Cutting Tools

Sandvik Coromant Parting Tool Provides Improved Surface Quality

CoroCut QD Y-axis parting tools feature upgraded blades with no Y offset, providing easier programming and increased stroke.

Read MoreKyocera Turning Inserts Provide Fracture, Wear Resistance

The KBN010 high-speed CBN grade gives users more flexibility, range, performance and tool life when turning hardened materials.

Read MoreTungaloy Boring Bar System Features Vibration Dampening

The BoreMeister boring bar system features a variety of exchangeable heads and shanks for internal turning, profiling, threading and grooving.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

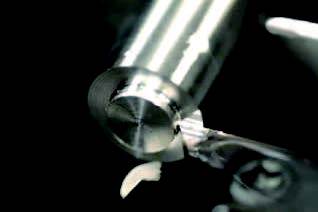

WatchAddressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

WatchParting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreWalter Indexable Drill Inserts Provide High Wear Resistance

The WNN15 drilling grade features a hard substrate, which provides high cutting-edge strength and sharpness on indexable inserts.

Read MoreThe Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read More

.png;maxWidth=300;quality=90)