Workholding

Dillon Soft Top Jaws Improve Concentricity, Chuck Balance

The soft jaws are designed to provide better concentric performance chuck balance, as well as enable a longer jaw life because of the increased jaw accuracy.

Read MoreFixtureworks Clamps Enable Heavy-Duty Machining

Nutrunner clamps are an alternative to hydraulic clamps and provide robotic clamping, automated clamping and unclamping on automated and robotic production lines.

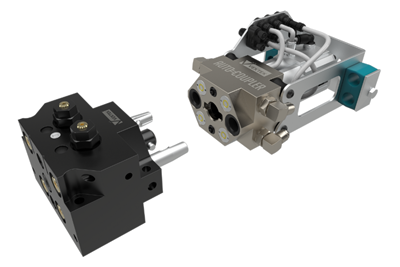

Read MoreVektek Automatic Coupling Device Provides Flexible Fixturing

Vektek’s Auto-Coupler features two independent air pass-thru circuits and provides the option of part present sensing and part confirmation.

Read MoreDillon Claw Jaws Enable Aggressive Turning

The jaws are designed to securely grip workpieces and minimize jaw clamping force losses.

Read MoreKurt Workholding Vises Provide All-Directional Alignment

The DXH Hydraulic vise lineup features the proprietary Kurt AngLock spherical segment to reduce jaw lift and improve performance.

Read MoreVideo Tech Brief: Bar Feeder Technology Optimized for Swiss-Types

This bar feeder design is said to offer high guidance quality with minimum vibration and noise development for sliding-headstock machines.

WatchDillon Workpiece Stops Reduce Setup Time

The workpiece stops enable short parts to be set above the jaws, providing clearance.

Read MoreRadial Pole Magnetic Chuck for Vertical Turning, Grinding

The system enables faster setup times, while pole extensions enable users to raise the piece from the magnet surface, making the top, inner and outer diameters fully machinable.

Read MoreDillon Extruded Aluminum Pie Jaws Are Stronger, Safer Than Castings

The pie jaws are machined from aluminum barstock, which means these large-diameter, full-grip pie jaws have none of the porosity inherent with castings, making them stronger, more reliable and safer than cast aluminum.

Read MoreWorkholding Facilitates Fast Changeovers for Robotic Surface Finishing Systems Manufacturer

This manufacturer finds value in modular workholding technology to speed production of toolholders and other components used in its automated surface finishing systems.

Read More

.jpg;maxWidth=300;quality=90)