Vektek Automatic Coupling Device Provides Flexible Fixturing

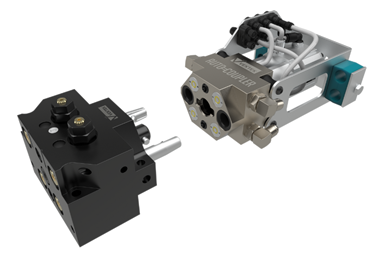

Vektek’s Auto-Coupler features two independent air pass-thru circuits and provides the option of part present sensing and part confirmation.

Vektek’s Auto-Coupler is designed to offer a variety of ways to couple fixtures and power sources, including manually loading parts and full robot automation.

Vektek’s Auto-Coupler features two clamp/unclamp circuits per pallet, which enables the use of other Vektek components to provide users the ability to sequence and reduce pressure of clamps on their fixture. In addition, two independent air pass-thru circuits are available and provide the option of part present sensing and part confirmation.

Vektek’s Auto-Coupler actuates its mechanical closure and lock with pneumatics. The mechanical lock separates and holds hydraulic force, and the two clamp/unclamp circuits feature cartridge-style pilot operated check valves — hydraulic circuits with SAE6/manifold ports conveniently located on the back or bottom of the Auto-Coupler. It also features two independent air pass-thru circuits — with 1/8 NPT / manifold ports on the back or bottom of Auto-Coupler. Integrated air blow off and filtration are included, as well as accumulators needed for any decoupled circuit.

Related Content

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

-

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

-

The Value of Swiss-Types Milling Rectangular Medical Parts

High-speed spindle technology was key to effective milling of small cardiac monitoring components complete on a CNC sliding-headstock machine platform instead of running them across two mills.

.jpg;maxWidth=300;quality=90)