A Multi-Spindle and Swiss Combination

At the recently completed EMO show in Hannover, Germany, the world’s machine tool and metalworking industry put on the biggest exposition on earth.

At the recently completed EMO show in Hannover, Germany, the world’s machine tool and metalworking industry put on the biggest exposition on earth. Production Machining’s plan is to bring several reports in the coming months on some of the new things that were on display at this huge trade show.

First is a new multi-spindle concept that had its world premiere at the show. “New” and “different” are often overused terms, but this new machine tool introduced by Tornos fits the bill. It’s a concept the company calls “Multi-Swiss.” The machine is a six-spindle CNC, but with the added benefit of providing sliding headstock capability on all six spindles.

Like a conventional Swiss-type, the Z-axis motion is generated by the stroke of the main spindle or, in the case of the Multi-Swiss, all six spindles working independently. The Z-axis stroke of this 14-mm-diameter machine is 50 mm with a maximum part length of 40 mm. Some may argue that because the machine lacks a guide bushing it is not truly a Swiss-type. But the point is that the Z axis is generated by the linear motion of the machine’s spindles, eliminating the need for compound slides on the cross slides.

The engineers at Tornos started this project with a clean sheet of paper. At the beginning of 2008, the company’s multi-spindle department began development of the Multi-Swiss 6 × 14 with the goal of providing a cost competitive, entry level CNC multi-spindle machine tool to aid shops that are transitioning from conventional cam actuated machines to CNC with no appreciable loss of performance or those that need more production capacity than can be delivered by single-spindle machines.

Therefore, they developed a fully integrated machine, which included the bar feeder, electronics, chip conveyor and ancillary equipment. According to Rocco Martoccia, the project manager for this machine at Tornos, “The decision was made early on to use 1.5-meter bars instead. There were several advantages to this choice: It reduces the machine’s footprint by 35 percent, it makes the handling the bars easier, and we can reduce the level of noise and vibration produced by running the machine.”

He continues, “However, we had to overcome certain obstacles such as the loss of efficiency owing to the number of feeding options required (twice as many for the shorter bars). We resolved this issue by feeding the bars four times faster than conventional bar feeders. Another point was to deal with double the amount of remnants that were generated with the shorter barstock. This problem was solved by generating remnants that are three times shorter than conventional machines.”

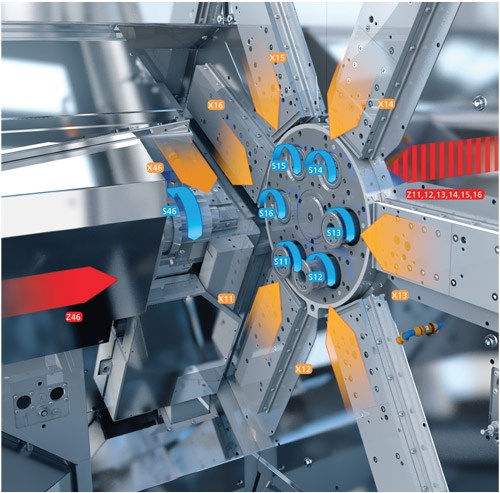

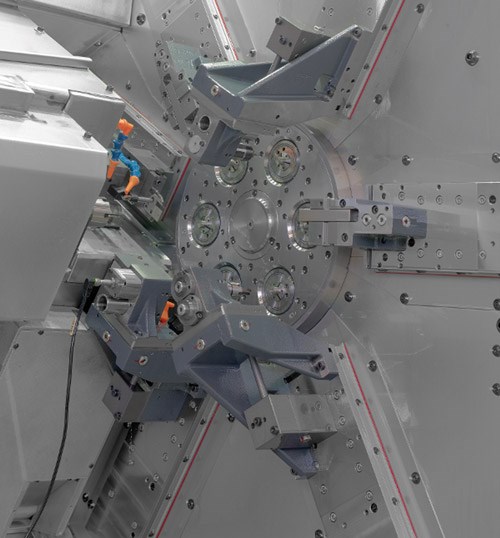

The heart of the machine is the spindle drum. Integrated 5.6 kW spindle motors with active cooling can rotate as much as 8,000 rpm, and each is independently programmable for the ideal cutting speed for the application. Instead of a coupling system to lock the drum in position, the machine uses a torque motor for indexing (0.3 seconds) and locking the drum in place at each station. The drum is hard wired, so a reverse unwind is part of the machine cycle.

In addition to its Z-axis stroke, each spindle has its own C-axis motion for interpolation with the X-axis cross slide. The spindle’s Z axis is ballscrew actuated and all six spindles use hydrostatic bearings for better damping during cutting operations.

Up to a maximum of 18 tools can be mounted on the machine with as many as three tools per position. It is also possible to mount various attachments for polygon milling and high-frequency drilling for main and backworking operations.

There is an independent backworking slide with capacity for two tools, which, when combined with the second operation drive spindle, allows for complex turning or milling operations that can be sequenced for zero cycle time impact.

The Multi-Swiss uses an integrated PC based control that is programmed using the company’s TB-Deco ADV software system. Designed to imitate the setup sheet used on conventional multi-spindle machines, this system simplifies programming on even complex workpieces using an easy to understand graphic interface. Programming can be done off-line or at the machine.

To date, some of the production parts that have been successfully processed across the machines include parts for the watch making industry, electronics, automotive and aerospace. The company has placed several beta test machines in shops around Europe, and the results have been good. The machine produces dimensional variations of 4 to 5 microns. Accuracy is consistent in large part because the machine uses an active oil circulation system that quickly gets the machine up to operating temperature and maintains that temperature throughout the run.

Although the new machine has a capacity of 14 mm, the concept is scalable to larger sizes, according to the company. Plans for delivery of these machines called for an October 2011 availability in Europe with North America scheduled later in 2012. However, if a shop is in the market for a CNC multi-spindle, this machine may well be worth a look.

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreGetting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)