Advances in Swiss-Type Technology

R&D efforts in recent years have led to higher efficiencies, increased agility and expanded capabilities for shops performing Swiss-type turning.

At a certain point in any machine tool’s life, it’s natural for a shop owner to wonder whether technology has advanced to the point that it’s time to invest in new equipment.

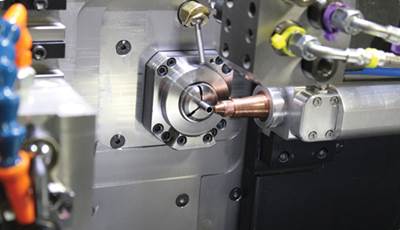

Take Swiss-type lathes: What advances have been made over the past decade that would justify such a capital investment? Plenty, as it turns out. Improvements include high-speed, chilled spindles for better material removal and machine stability, B-axis positioning for feature contouring, reliable automation for loading and unloading the lathe, high-pressure coolant systems for chip clearance and processes such as gun drilling, and the ability to hold tight tolerances repeatedly.

In addition, what were once expensive options—such as the ability to convert from a Swiss lathe to chucker mode quickly and easily—are now being included in standard machine tool packages, delivering a powerful array of machining capabilities. Add to that laser cutting, eliminating the need for a secondary operation, and sensors supporting data-driven manufacturing, and it becomes that much easier to achieve a timely ROI.

Keeping Your Cool

According to Graham Noake, vice president of Tsugami/Rem Sales (Windsor, Connecticut), about 10 years ago, the company observed the competitive landscape to identify improvements that could be made to both the design and the functionality of its Swiss lathes. Known for its commitment to achieving thermal stability in its machine tools, the company also realized this had resulted in a somewhat confined tool zone, since one way to control and stabilize the interior temperature was to keep the enclosure relatively small. However, a small tool zone limited the number of tools that could be used at once and shortened the length of tool travel.

To accommodate a larger cutting zone, which allowed more tools to be introduced into the cut at the same time, as well as longer tool travel distances for additional flexibility in approaching the workpiece, chiller units cooling the interior of the machine as well as the chilled spindles were implemented. Mr. Noake points out that this design is meant to achieve thermal consistency within the machine rather than the workpiece, since the parts are so small that little heat is generated. Glass scales can also be used to help detect temperature fluctuations.

The improvement of the high-pressure coolant system is another technological progression. While these systems have been around for years, the pressure has improved so they can now deliver 2,000 psi or more. The benefits of such a system include improved chip clearance, but more importantly, the system enables processes such as gun drilling—the deep hole drilling process that produces holes in metal at high depth-to-diameter ratios using a long, thin cutting tool. High-pressure coolant systems can also eliminate peck drilling, a time-consuming machining procedure in which the cutting tool is repeatedly introduced into the hole and then withdrawn in order to clear chips from the tool as well as the hole being drilled. Other benefits include extended tool life and the ability to cut more exotic materials such as high-temperature alloys and tool steels that once posed difficulties in the ability to break off chips cleanly. Systems can handle both oil and water-based coolants, although oil is typically used, and the cut is flushed of chips, both through the tool and using the flood method.

Mr. Noake estimates that approximately 75 percent of the Swiss machines the company installs now feature high-pressure coolant. A decade ago, only around 10 percent of its machines featured high-pressure coolant.

Improved Machining Processes

In addition to the sliding headstock, which performs double duty as the machine’s Z axis and main spindle, the guide bushing is central to the design of a Swiss-type lathe. The guide bushing provides support for long, thin workpieces by allowing the X-axis cutter to be close-coupled to the spindle nose. It feeds radially as the Z axis feeds axially.

When machining short, thick parts, however, with low length-to-diameter ratios that are typically smaller than 3-to-1, the support the guide bushing provides isn’t necessary since the workpiece is rigid enough to support itself without deflection. Non-guide bushing setups eliminate the need for purchasing a more expensive ground barstock, and it also results in shorter remnants. The ability to use a Swiss lathe in chucker mode is known as “convertibility,” which takes no more than 15 minutes, allowing for rapid change-overs as needed. Most Tsugami Swiss lathes feature this capability. It allows for the machining of non-barstock such as headed blanks, cut-to-length blanks and pre-cut tubes.

The introduction of a B-axis milling spindle is another improvement. This addition allows for cutting angle holes and improved contouring of features that might otherwise have to be machined separately, requiring moving the part to another machine. This ability enables machine shops to bid on parts with features that they couldn’t have machined before, especially since the B-axis spindle can be mounted with dozens of different tools, Mr. Noake says. The additional axis allows the Swiss lathe to have five-axis CNC machining center capability.

As any shop owner knows, one of the keys to successful production is to eliminate as many extra moves as possible, especially when it comes to secondary and even tertiary operations. The ability to machine a part complete in one setup is crucial to remaining competitive in today’s manufacturing environment, which Tsugami/Rem Sales has addressed with the addition of laser cutting to its Swiss-type lathes. Although the process is ideal for making medical components, more uses are being identified as operators become more familiar and comfortable with the concept of laser Swiss machining, according to Dale White, laser product manager at Innovative Machinery Group (IMG), a division of the Morris Group along with Tsugami distributor Rem Sales. IMG primarily handles systems integration. Applications are increasingly being found in markets including aerospace and automotive, where tight tolerances and the machining of intricate features are required.

Six models in the LaserSwiss line are available with 250W and 400W fiber laser cutting systems by SPI Lasers UK. One of the Swiss line models carries up to 36 tools plus the laser, while a second model has seven axes and includes a B-axis tool block containing the laser.

Seeking New Technologies

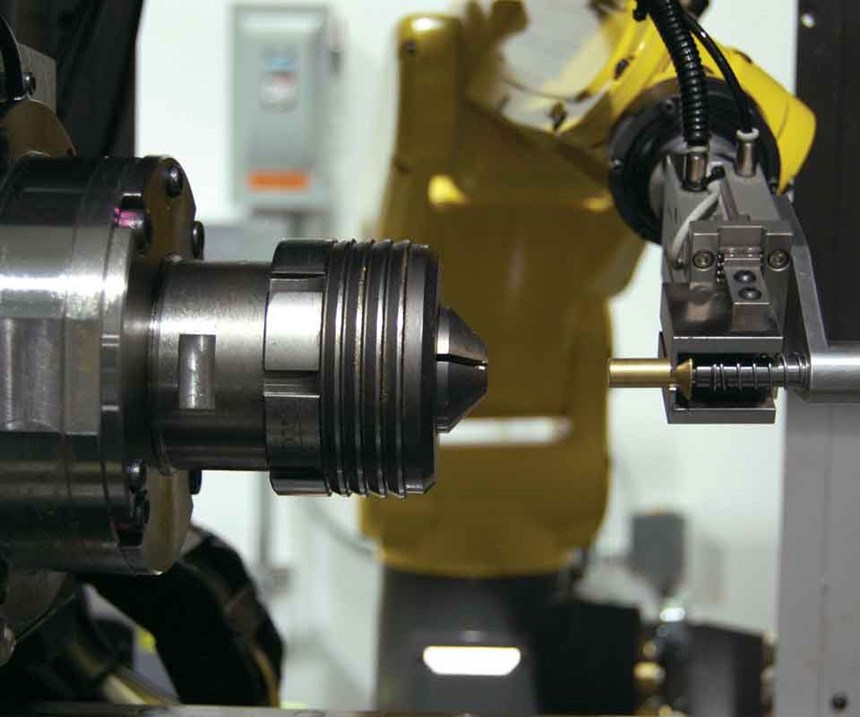

As Swiss-type technology has evolved, with new features and capabilities constantly being employed in the machine tool’s design, relationships with vendors have become increasingly important. Just as Tsugami/Rem Sales has chosen SPI as its laser supplier, it has also formed longstanding relationships with other partners. When it comes to bar feeders, its vendor of choice is Edge Technologies—a Hydromat company—because of the breadth and flexibility of its product line. Edge offers short bar loaders that can handle 4-inch bars as long as 60 inches in length to 6- and 12-foot magazine loaders that can feed up to 2 inches in diameter.

In the same way, the machine tool company relies on FANUC for both its automation and controls, and it works closely with a precision bearing manufacturer on the high-speed spindles it offers on its machines. As an example of the benefits associated with these longtime partnerships, the spindles mounted in the lathes have proprietary technologies and features developed at the company’s request.

A relationship with Caron Engineering has led to the development of machine monitoring systems for data-driven manufacturing. In short, data-driven manufacturing is the collection via sensors and application of data describing the machine’s operating conditions. Tsugami is making use of Caron’s Tool Monitoring Adaptive Control (TMAC) system, which is only one package among the company’s software suite. The tool monitoring aspect of the system monitors for excessive tool wear or even breakage, alarming out the machine and notifying the operator. This is especially helpful when conducting lights-out machining. The adaptive control function optimizes material removal and automatically adjusts feed rates in order to reduce cycle times by keeping the spindle motor power constant. Additional sensors enable the system to monitor coolant flow and pressure, machine vibration, spindle speeds and even the condition of micro-tools. The two companies have even worked together to develop a system that actually measures a part “in process,” or while the tool is still within the cut.

By leveraging the expertise of these various partners, Tsugami/Rem Sales delivers better outcomes for its customers, since each company’s philosophy and objectives are clear from the start.

Design Implications

In summing up how Swiss-type machining advances have benefited precision machine shops, Mr. Noake makes a powerful observation: Many of the parts now routinely being run across a Swiss lathe, he says, simply couldn’t be made any other way. While secondary processes such as wire and sinker EDM might be able to make the cuts, given time, laser Swiss machining is faster, more precise and more economical. It’s part of the drive toward multitasking that has been a Swiss-type machine hallmark for more than a century. And even beyond the process improvements, there are design implications that are leading to new ways of thinking about how a part can be made; in much the same way that additive manufacturing has freed design engineers from considering subtractive manufacturing as the only way to make parts, laser cutting—combined with the known benefits of Swiss-type machining—offers fresh approaches to making medical, aerospace and automotive parts more quickly and with more precision than ever before.

For more information from Tsugami/Rem Sales, call 860-613-6393 or visit remsales.com.

For more information from SPI Lasers UK Ltd, call +44 (0)1489 779 696 or visit spilasers.com.

For more information from Caron Engineering, call 207-646-6071 or visit caroneng.com.

For more information from FANUC America, call 888-326-8287 or visit fanucamerica.com.

For more information from Edge Technologies, call (888) 635-6057 or visit edgetechnologies.com.

Related Content

Sandvik Coromant Inserts Provide Stable Turning of Aerospace Components

The new insert grades GC1205 and GC1210 cover a large application area within last-stage machining and intermediate-stage machining when turning aerospace engine components.

Read MoreT.J. Davies Retention Knobs Harden Over Time

Each retention knob is magnetic particle tested and pull tested to 2.5X the pulling force of the drawbar it is designed for.

Read MoreHow Small Machine Shops Can Fight Supply Chain Problems

Supply chain disruptions are still presenting challenges in manufacturing. This article examines the effects on aerospace, automotive and medical industries. It also covers ways that machine shops can be successful securing work despite the challenges created by the supply chain.

Read MoreForkardt Hardinge Swiss Workholding Provides Reliable, Consistent Performance

The company’s Swiss collets are designed to securely hold parts without marring surfaces, minimizing vibration to ensure smoother machining, enhanced accuracy and extended tool life.

Read MoreRead Next

Swiss-Type with Laser Cutting Capability

New capability for Swiss machines uses a laser.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)