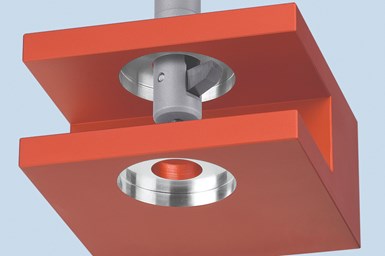

The BSF Air tool was designed to machine a flat spot on the backside of a part for a fastener or washer to set. Usually, the tool is used for truing up material. Photo Credits: Heule Precision Tools

Although there are a few methods for actuating an automatic back-spotfacing and back-counterboring tool, one Swiss tool manufacturer has discovered a way to actuate this cutting tool which its customers say helps decrease cycle time. With its BSF-Air air-actuated tool, Heule Precision Tools has expanded its offering that, until recently, was only available as a coolant-through tool from the company.

The coolant-through version of the tool offers the benefits of chip-guiding geometries that continuously flush the tool’s blade window and the blade itself with coolant for optimal chip removal, the company says. However, the BSF-Air is a back-spotfacing tool option for machine tools that do not offer through-tool coolant delivery or for parts that can’t be machined using coolant due to cleanliness reasons. This air-actuated tool provides many of the same advantages of the coolant-through tool, with the added advantage of faster tool activation. Because of its quicker tool functionality, especially high production machine shops are benefitting from the air-actuated tool, according to Bill Hargrove, national sales manager at Heule.

“Many times, to fire coolant through the spindle, the machine goes through a cycle that takes several seconds to turn on and turn off,” he explains. “It can take a little bit of time for the coolant to build up enough pressure to activate the tool. Conversely, the air activates quicker, helping reduce cycle times.”

The Mechanics

Like the company’s BSF tool, the BSF-Air does both back-spotfacing and back-counterboring in one operation without the need to flip the workpiece. Designed to be used vertically or horizontally, it is also an automatic tool that functions without an anti-rotation device, change of spindle direction or contact mechanism.

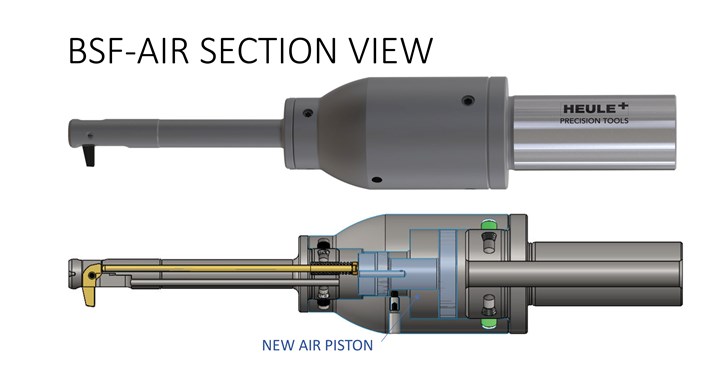

The air-actuated tool is mechanically designed the same as the coolant-through tool, Hargrove explains. However, a different shank is used for the air-actuated tool that enables it to activate with air instead of coolant pressure.

After the tool enters a through-hole and spindle rotation starts, centrifugal force opens the carbide retractable blade. The tool with blade open then moves back toward the hole to proceed with the back-spotfacing and/or back-counterbore process. When the cut is complete, the blade retracts back into the tool body via air pressure. This occurs when the air pressure running through the tool forces the piston (at the top of the inside of the tool) to push the blade on the other end of the tool back into the tool body, completing the process.

Like any cutting tool, the carbide-coated blades of the BSF-Air will eventually wear down with use. However, the blades can be easily replaced by the user, so the entire tool does not need to be replaced.

The air-actuated tool is mechanically designed the same as the coolant-through tool. However, a different shank is used for the air-actuated tool that enables it to activate with air instead of coolant pressure.

Applications, Materials, Sizes

The BSF and the BSF-Air are critical tools for the processes they perform. Hargrove explains that back-spotfacing and back-counterboring processes can only be accomplished using a tool specifically for that operation — no other cutting operation can perform these processes.

These types of applications include machining a flat spot on the backside of a part for a fastener or washer to set. “There are some instances where they put large, deep holes in the material, but typically that’s not the case,” Hargrove says. “Usually, the tool is used for truing up the material.”

These tools are designed to not only complete these specific processes but also to eliminate the need for secondary operations. The back-counterboring operation cuts the backside of a part without having to stop the operation, flip over the part, reclamp it and machine the other side. This saves a significant amount of time for any operation.

The tool — which can cut simple, light-duty metals as well as aerospace nickel-based materials and anything in between — is available in sizes from 6.5 mm (0.256 inch) to 20.5 mm (0.807 inch). It produces counterbores up to 2.3 times the diameter of the through-hole as well.

A Short Success Story

One high-production automotive machine shop had been using Heule’s BSF coolant-actuated tool on at least seven of its machine tools for many years, Hargrove explains. But when the machine became a bottleneck, Heule offered the company the BSF-Air tool and tested it on the shop’s machines.

By switching to the air-actuated tool, the shop saved 2 seconds per hole, and each part contained eight holes that needed to be back-spotfaced. Therefore, the company saved 16 seconds per part on one machine.

Related Content

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreNew Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

Read MoreWhat Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreRead Next

Automated Deburring Made Simple

With its X-Bores series of deburring tools, Switzerland-based Heule has developed solutions for the automated deburring of cross bores.

Read MoreDebunking the Deburring Process

A car manufacturer struggled with a complex and unreliable deburring process for its crank case production line until it was introduced to a tool designed specifically for cross-bore deburring.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.JPG;maxWidth=150;quality=70)

.png;maxWidth=300;quality=90)

.JPG;maxWidth=400;quality=70)