When I woke the morning of May 4, I asked Siri for the weather report on my iPhone, and then asked Alexa on my Amazon Echo to play a music playlist while I got ready for an on-site visit to compile information for this article. Later that morning, I drove to a machine tool rebuilder’s location close by and asked Athena to “cut wire” on a wire EDM.

Who is Athena, you might ask? “It” is a voice-operated system for machine tools and works much like Siri and Alexa. Athena’s developer set up a demonstration in Cincinnati, Ohio, where I live, which gave me an opportunity to experience the technology hands-on.

Although I know many precision machine shops do not own wire EDM units, my contact for the article offered the Athena demo on a Makino wire EDM, so I took him up on it.

As voice-assistance technology becomes a popular way to search for everyday information for anyone with a smartphone, smart speaker and even a smart automobile, Athena’s developer, iTSpeeX LLC, is working toward perfecting voice-operated assistance for CNC machine shops, specifically for machine tool operation. iTSpeeX’s Athena listens to and follows simple voice commands. However, Athena is much more advanced in its abilities because it can not only initiate physical tasks on a machine tool such as setup, calibration and maintenance but can also run programs and reports, send emails, record and play back messages, and much more. Athena's functionality could save both experienced and inexperienced operators time and boost efficiency by guiding them through simple and complex machining tasks, simplifying machine tool training and reducing errors with optimization.

iTSpeeX, a startup company consisting of private investors with manufacturing backgrounds, began in 2018 with the idea of helping remedy manufacturing’s skilled worker shortage problem. The company initially created Athena as an aide for unskilled operators, but since then the system has grown in its list of capabilities to assist skilled machinists as well. The company works directly with machine tool OEMs to understand their operating systems and how their controls communicate with their machines.

“We want to ensure that the OEMs know and feel comfortable that we are not overriding any safety features and are working directly with their interfaces.”

“If we worked with individual shop owners in the beginning, we’d still need to go to the OEM to get those communication pieces in place,” says Jerry Rex, iTSpeeX chief revenue officer. “Plus, we want to ensure that the OEMs know and feel comfortable that we are not overriding any safety features and are working directly with their interfaces.”

Athena resides on either a machine’s PC-based control or a separate PC that is intentionally not connected to the internet. According to Rex, there are a lot of machine shops whose IT departments will not allow internet connection. There are safety and security risks that come with an internet connection, so the company has designed Athena to function on-premises.

In addition to machining centers and EDM, iTSpeeX is working with several machine tool OEMs to implement Athena on a range of CNC turning centers, according to Rex. He notes that Athena’s potential to move into the precision machining market is promising, though. Machine tool builder Makino was the first adopter of Athena that saw the potential and opportunity within the technology, and has so far made it available on the company’s wire EDM units.

To understand Athena’s functionality, value and promise for the precision machining industry, this article answers three questions about the technology that I learned during my demonstration, written as Athena commands.

‘OK, Athena. What Can You Do?’

Athena has a long list of functions that are helpful to an operator, including completing a startup checklist, machine setup, tool setter initiation, machine and tool status updates, alarm reports, run programs, guiding new procedures, learning new skills, sending email reports and showing part drawings. It also plays how-to videos on its touchscreen when commanded and can locate pages in a machine’s extensive operator’s manual or do a search within the manual for a specific topic.

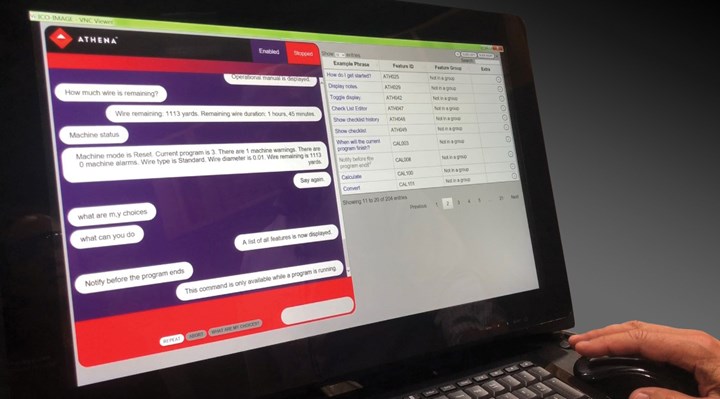

This screenshot shows examples of commands for Athena and responses from Athena in the purple and red box. An operator can choose to type a question or number into the space instead of using voice commands.

Simple commands from the machine’s operator given through a headset (or a keyboard) direct Athena to guide the operator through a process or have the machine do the process itself. “Ok, Athena,” are the wake words that tell the system to listen to the command. After a pause, the operator then tells it what to do. “Edit program 3,” “Close program,” “Machine status,” “Estimated cycle time or feed rate” and “What are the M codes” are some of the commands to which Athena responds. An operator can also say, “OK, Athena. What can you do?” and a list will show available commands.

As I realized during my demo, getting used to the speech rhythm and properly responding to Athena takes some patience and practice. Rex explains that the technology has all the information needed and will guide the operator and protect him or her from making mistakes at the machine tool.

Athena’s checklist capability is another option that Rex thinks can be an asset to an operator. OEMs have the option of creating built-in checklists, but an end-user can create their own checklist as well that can include daily, weekly or monthly preventive maintenance or startup tasks, for example.

‘How Do You Add Value?’

Athena guides, simplifies and optimizes the machining process for operators, saving time and money, while increasing accuracy, consistency, communication and awareness. Athena also helps a machine shop avoid downtime, predict repairs and identify issues on a machine.

Because shops might have a limited amount of talented, knowledgeable workers, Athena is designed to empower the person in front of the machine, Rex says. Because it is easy to use and supports not only English but also Japanese, German and Spanish, it can give a novice operator a chance to learn how to use the machine, and it can also remind an expert to do certain tasks that he or she might not remember to do.

“A shop may have one setup person for five or 10 machines,” Rex explains. “And, if that person is busy on another machine, the ability to have a piece of that person's brain or knowledge at the machine tool control is pretty powerful.”

Athena can reside either on a machine’s control PC or a separate PC that is not connected to the internet. Jerry Rex, chief revenue officer, iTSpeex, says the company purposely doesn’t connect Athena to the internet for safety and security reasons. Here, Rex is showing Lori Beckman, senior editor of Production Machining, how Athena works.

The time savings and efficiency the technology offers can be quite beneficial to a machine shop. “Whether an operator is a novice or an expert, Athena quickly retrieves the latest information from the machine tool,” Rex explains. “Also, simplifying complex processes/procedures/

functionality, whether they are multiscreen deep, very complex or proprietary features that an OEM might have built in, getting to those and getting to them quickly are the biggest advantages.”

He also believes Athena will help reduce call support volume and OEM visits to customer locations.

‘What Else Should Machine Shops Know About You?’

Athena is not limited to talking to the machine and having it answer or move in response to a command. An operator can type on a keyboard what he or she hopes to accomplish, can say, “What are my choices?” or click on an item on the screen or do a search. It can pull up a PDF, remind the operator to complete a critical machining step, guide him or her through steps, or immediately find a short how-to video. Rex says these are all important features, especially for operators who might not be regularly working on that particular machine.

Athena can be retrofitted. For machines already on the shop floor, no matter their ages, Athena can be added to it, according to Rex. “We see retrofitting as one of the biggest opportunities for OEMs and end-users,” he says. However, he stresses the importance of working closely with the machine tool builder to do so. A shop could have Athena retrofitted to the same brand machines on the shop floor, so it is not only available on the newest machine.

Athena can record messages. An operator can record a note for the next operator on that machine to provide critical or helpful information — for example, “You better check tool 12. I noticed a little bit of noise.”

Beckman talks to Athena on a machine tool as she learns about what questions to ask the voice-operated assistant.

Always considering ways to improve and grow Athena’s competency, iTSpeeX is currently developing Athena 2.0, with the goal of making the interface more user-friendly. The company is creating access to work orders, part information and renderings on Athena’s interface. Although it will not go as far as writing an ERP system, the company aims to add value by interfacing with ERP tickets and systems.

Related Content

Reinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreRead Next

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

Read MoreA Beginner’s Guide to Automation

While many shops are enjoying the production benefits of robotic part handling, others are struggling to tackle the first steps of implementation. Here’s a basic guide to help provide clarity on where to begin.

Read MoreInterest in Robotic Automation for CNC Machine Shops Increasing

Have you considered how robots can be beneficial to your shop?

Read More

.jpg;maxWidth=300;quality=90)