Automation System Loads up Expandability, Scalability and Precision

Determining the scope of an automation system involves trying to anticipate a facility’s future needs, and system design, assembly and installation can include long lead times and significant expense.

Manufacturing automation technology boosts productivity, profitability and global competitiveness. However, many shops are reluctant to commit to an automation system because of concerns about flexibility and cost. Determining the scope of an automation system involves trying to anticipate a facility’s future needs, and system design, assembly and installation can include long lead times and significant expense.

The System 3R Transformer modular automation system from GF Machining Solutions addresses those concerns. The system is expandable and scalable; a shop can begin with automation of one or two machines and then easily expand the cell to include as many as 12 stations. The system’s adaptability and flexibility ensure that it will never be too specialized or too small to meet a facility’s future requirements.

OEM automation systems often are designed to integrate certain machine tool brands or styles. The open architecture approach of the Transformer system permits integration of differing manufacturing technologies including mills and turning centers, EDM machines, measurement devices and even parts cleaning equipment. Unconstrained by compatibility issues, individual operations can be optimized and incorporated to achieve full automation of an entire process.

Breaking it Down

The basic components of the system are a robotic pallet changing unit and modular racks or rotating magazines that store pallets fitted with referencing chucks from System 3R. The chucks provide repeatability of 2 microns and enable the transfer of parts from one machine to the next without the need to check positioning or repeat setups.

System 3R tooling allows palletization of workpieces and EDM electrodes of a range of sizes. Different versions of the system feature pallet sizes from 54 mm × 54 mm to 700 mm × 500 mm, and the pallet-changing robot can handle part/pallet combinations weighing as much as 440 lbs (200 kg).

In a one-, two- or three-machine cell, a stationary robotic changing unit accesses either a bookshelf-style or a rotary pallet magazine. A rotary magazine provides 3 times the capacity of a bookshelf magazine, in the same amount of space.

To handle as many as 12 machines, the pallet changing robot rides on a modular rail system. The rail system is made up of standardized sections that can be quickly added and linked to produce the length needed to service the number of machines desired for the cell.

Flexibility for the Future

Most automation arrangements are engineered to meet the requirements of specific part production and shop environments. Expanding or changing the system requires dismantling the prior setup and building a new one from scratch. With the Transformer system, on the other hand, the standardized modular components combine to create customized automated solutions. Together, the modular nature of the robotic handling, rail and magazine components and easily updated software enable the system to be expanded or modified in a matter of a few days rather than in the weeks or months required with traditional automation arrangements. Plus, modularity and simple connectivity enable a shop to expand a Transformer rail system while the rest of the system continues to operate. Standardization of components also contributes to lower equipment costs.

There are two control modes for the system. It can be operated as what is called a simple system, which works much like a toolchanger in that the machine tool sends direct commands to the robot. Or for multiple machine cells, full capability and flexibility is achieved with the use of WorkShopManager software, which links all machining processes together in a clearly arranged production system. The software’s CellManager engages with pallet identification systems, including visual labels or RFID technology, to record the position of every pallet at any given moment. This process permits control of every aspect of the cell, from automatically loading jobs to each machine to recording and monitoring cycle times for each operation. Production data can be entered manually or imported through a data exchange interface with major enterprise resource planning (ERP) systems.

The software permits random loading of pallets and on-the-fly modification of work order and priorities. As a result, the system handles small and large production lots with the same level of efficiency, to the extent that automated one-piece production is possible. When a cell houses a variety of processes, the WorkShopManager software is especially effective in maintaining production flow.

A Good Fit

According to GF Machining Solutions, payback on the investment in a Transformer system is rapid—a result of significantly increased machine utilization. The system’s accuracy and reliability permit lights-out operation that multiplies machine utilization by a factor of three or four.

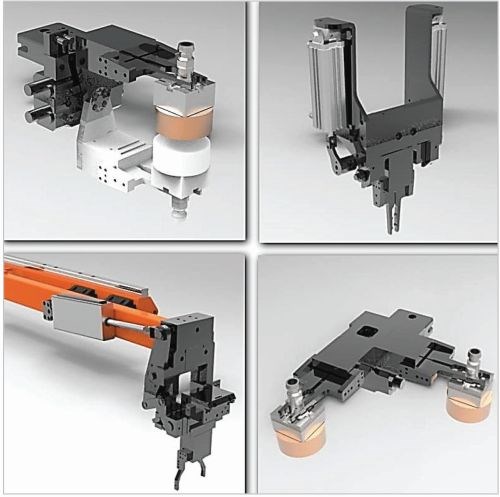

A selection of grippers, including turning, tilting, tipping arm and double-effector units is available to maximize flexibility of the pallet-changing robotic unit. In-process accessories that enhance system capabilities include in/out loading stations for larger pallets that can be operated without stopping production, a station for draining workpiece cavities after they are machined and a cleaning station that prepares a part for precision inspection on a CMM.

The automation system is especially suited for lights-out production of small- to medium-size precision components in tool and die and moldmaking operations, as well as any other tight-tolerance manufacturing applications.

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreJob Shop Discovers and Fills a Fishing Need

The promise of a product line for improved mounting of electronic fish finders led this Missouri job shop to an automated turning process.

Read MorePursuit of Parts Collector Spearheads New Enterprise

While searching for a small parts accumulator for Swiss-type lathes, this machine shop CEO not only found what he was looking for but also discovered how to become a distributor for the unique product.

Read MoreAutomation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

Read MoreRead Next

Technology Advances Automation Trends

Shops of all sizes looking for better efficiency are realizing the benefits of a deeper investment into automation.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)