Ban The Burr—A Look At ECD

Deburring is a consideration, and often a problem, for all manufacturing engineers. The burrs resulting from a metalworking operation may be tolerable; however, burrs are always present.

Deburring is a consideration, and often a problem, for all manufacturing engineers. Many engineers will claim a part is produced “burr-free.” This is usually a fallacy. The burrs resulting from a metalworking operation may be tolerable; however, burrs are always present.

When the engineer determines a burr must be removed, numerous manufacturing processes are available from which to choose. An important element of this decision is the “make or buy” decision regarding the purchase, operation and maintenance of specialized in-house deburring equipment versus sending parts to a qualified contract deburring job shop.

Electrochemical deburring (ECD) is a localized deburring process that uses electrical energy to remove burrs in a specific location. The part to be deburred is placed on a nonmetallic holder that locates an electrode in the exact vicinity of the burr or burrs.

The workpiece, which functions as an anode, is charged positively, the electrode (cathode) is charged negatively and an electrolyte solution is directed under pressure to the gap between the burr and the electrode.

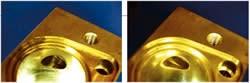

The flow of electrolyte precedes the application of the current to flush out any loose chips that may cause a short in the system resulting in damage to the part, the tooling and/or the equipment. A very controlled radius is generated as the burr is dissolved. ECD is often thought of as reverse plating in a localized area. The ECD process is extremely consistent from part to part and from lot to lot.

Fixturing is always required for ECD. The typical fixture, unique to the part, consists of a plastic locator (to hold the part and to insulate or “mask” areas of the part not requiring ECD) and a highly conductive metallic electrode. The electrode is designed with a contour that conforms to the desired dimensional characteristics of the area to be deburred. The flow of electrolyte is directed by the locator and/or the electrode, depending largely on the specific techniques used by the fixture design engineer. The manufacturing engineer has precise control of the ECD process through the variables of voltage, current, electrolyte flow and cycle time.

ECD will change the dimension of a part only to the extent of removing the burr, leaving a controlled radius. Thus, the dimensional change is desirable and is generally required to make a part “to print.” The process will only affect areas of the part in the vicinity of the electrode if the fixture is properly designed and maintained.

As previously mentioned, the locator can be designed to protect critical areas and/or surfaces, including threads, although ECD is extremely effective in removing burrs in threads, which are the result of milling and drilling through the thread form.

ECD is another manufacturing operation to be used as a “tool” by the manufacturing engineer. Fast production and consistent results are major advantages of ECD. Some other benefits should be noted about ECD:

- Eliminates costly and time-consuming hand deburring

- Achieves a controlled and blended radius at intersections

- Removes otherwise inaccessible burrs

- Ensures that all burrs are consistently removed on every part

- Increases quality and reliability

On the downside, because ECD is only effective on electrically conductive workpiece materials, other deburring processes must be used for processing plastics and other non-conductive materials. Also important to consider, the workpiece must be cleaned prior to ECD. All oil and other metalworking fluids, as well as all loose and/or unpacked chips, must be removed. Metalworking fluids will contaminate the electrolyte and will also mask the ECD action. Chips can cause electrical shorting, resulting in damage to the workpiece and the fixture.

The burrs are electrochemically dissolved and the metal becomes a sludge that must be properly disposed of in accordance in with local, state and federal environmental laws and requirements. Depending on the material involved, this could include handling heavy metals such as chrome and nickel.

Make Or Buy

ECD is a specialized process requiring planning and up-front engineering to be successful. When the application is correct, ECD can save time and money and ensure consistent, quality burr removal. The question for precision machined parts manufacturers is whether to perform ECD along with other in-house deburring operations or vend the work out to specialty shops.

Generally, the justification to invest in deburring equipment is based on the quantity of parts to be deburred and the security of the job being run. ECD requires tooling and fixturing, so run quantity and job life are key deciding factors. For companies that cannot justify the purchase and associated costs for in-house equipment, contract deburring job shops can provide a cost-effective alternative.

Many companies will begin by using the services of a job shop for one or two batches of parts. This early experience provides the shop with a certain level of confidence in the deburring processes. As this confidence increases, more and more parts are sent out to the job shop for processing. At a certain point, it may make economic sense for the shop to consider the purchase of the equipment.

Although the economics may dictate the purchase of deburring equipment, other factors need to be considered. With the current trend toward specialization—and ECD is specialized—it has become virtually impossible for most companies to be experts in all aspects of producing their product.

Contract deburring job shops offer a hassle-free turnkey solution for most deburring problems. If for some reason the job shop solution does not work out for a particular company, the equipment can still be purchased. If it does work out, the company has saved considerable capital resources that can generate additional profits, which is what we are all here to do.

— Vectron Inc.

Read Next

Ceramic Fibers For Precision Deburring

Removing burrs from precision machined parts is the bane of every metalworking shop. These pesky residuals add to the cost and complexity to most production processes. Moreover, most customers for precision parts mandate a zero-tolerance policy for burrs.

Read MoreBolt On Deburring

Burrs are a nemesis for most metalworking shops. And cross-hole burrs are among the worst cases that shops encounter. For most applications, deburring must be done off-line as a secondary operation.

Read MoreNew Tools Automate Hole-Deburring

New tools increase the efficiency of automatic hole deburring. Some can handle holes as small as 0.030 inch diameter.

Read More

.jpg;maxWidth=300;quality=90)