Benchmark Your Machining Business

By taking the Top Shops benchmarking survey, you can see how your operation’s metrics and practices — both in the front office and shop floor — compare to leading U.S. machining businesses.

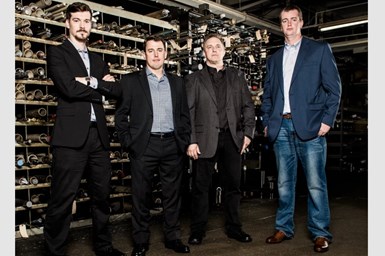

Representatives of two of the four Top Shops Honors Program winning companies in 2018 are Production Machining readers — Kylan Hastreiter, vice president of Hastreiter Industries (left) and Andy Reinwald, president of Ripley Machine (right).

I’m no stranger to sister publication Modern Machine Shop’s Top Shops benchmarking program. Before moving to Production Machining magazine, I helped manage our sister publication’s program with its annual survey for the first nine of its now 11 editions.

I know some Production Machining readers who aren’t strangers to it either, as I know of some who have participated in the survey in the past. Perhaps that’s you. But if you’re unaware of this free survey and the advantages of participating, please read on.

At the center of the program is a confidential survey divided into four main categories: machining technology, shopfloor practices, business strategies and human resources. It includes prompts for key performance indicators, best practices and technology applied in both the front office and shop floor.

The survey is currently live at survey.mmsonline.com/topshops and is open throughout the year. Shops that complete it will receive a free custom report comparing its data with all others that completed the survey. The report also indicates the areas in which the company is particularly strong, on par with others or should target for improvement.

Visit survey.mmsonline.com/topshops to take this year’s benchmarking survey and get a free custom report.

Shops that complete the survey by March 30 will be considered for the Top Shops Honors Program in which one participating company in each of the survey’s four aforementioned sections is honored and profiled in Modern Machine Shop.

What’s new to this year’s program is the chance to opt in on the Top Shops Sourcing Platform. More than just a sourcing database, this platform is a free sales and marketing tool designed to help U.S. job shops and contract manufacturers connect with sourcing, purchasing and procurement professionals looking to source parts and products from an exclusive and qualified list of U.S. manufacturers. You can learn more at topshopsevent.com/sourcing.

In addition, later this year, we will publish an article that breaks down the Top Shops data so that it better reflects manufacturers serving our high-production industry for a bit more apples-to-apples comparison to leading U.S. production machine shops.

Similarly, Steve Kline, chief data officer for our company’s Gardner Intelligence group, will be presenting his analysis of that high-production group at this year’s Precision Machining Technology Show (PMTS) held in Cleveland August 10-12. So, that makes it all the more important that shops like yours participate. For this survey, many more job shops that produce in small batches take the survey compared to high-volume operations that Production Machining readers own or manage.

Plus, Gardner Intelligence now can cut Top Shops data in a variety of different ways to present the precise information you might need. For example, perhaps you’re only interested in seeing your data compared with shops that serve the medical industry, or those that use Swiss-type lathes, or those that are located in the same region as you. It’s also possible for shops that don’t participate in the survey to purchase general reports from Gardner Intelligence at gardnerintelligence.com.

Know that the survey is lengthy, and you might not have some figures at your fingertips to enter online. That’s why it’s a good idea to print the survey so you can gather that info and input it all in one sitting, being sure to hit “submit” at the end.

Email me at dkorn@productionmachining.com if you have any questions. This program is still very fresh in my mind.

Read Next

Video: Adopting Continuous Improvement as Company Culture

Continuous improvement is an ongoing investment into identifying opportunities for boosting efficiency and reducing waste. This article shares advice from machine shop managers to other machine shop managers about continuous improvement plans that have worked for their companies and the benefits they are enjoying as the fruits of their labor.

Read MoreOur Precision Machining Industry Responds

This moment-in-time article describes the challenges multiple precision machine shops faced — and met — to support customers’ and employees’ needs during the COVID-19 pandemic.

Read MoreMeet Production Machining’s 2020 Emerging Leaders

This year’s 10 Emerging Leaders have many character traits in common that shine well beyond the buildings in which they are employed. Their leadership skills and willingness to help others grow within their skill sets has proven that the precision machining industry’s future is bright in the hands of these talented individuals.

Read More