Beyond One and Done

Rotary transfer machining is one proven solution for high volume machining. Today’s CNC rotary transfer machines provide more than “set it and forget it” production; they are flexible enough for high mix and low volume production demands.

Despite the current political rhetoric about international trade agreements and lack of an even playing field, manufacturers do, indeed, compete in a global marketplace. The fact is, competition is everywhere. It not only comes from across the seas, but also from down the street and around the corner as all manufacturers vie for their share of jobs.

This is especially true of high volume production where winning a major contract can come down to a difference of pennies per part. Add to this the need to achieve increasingly tighter tolerances, and few in manufacturing would argue that we live in challenging times.

Reducing the Cost per Part

The accepted way to bring down high volume production expenses is to reduce labor and material costs, while maintaining mandated tolerances. To make large quantities of parts that require multiple machining operations, the best solution may be a CNC rotary transfer machine. These versatile machines enable true “one-and-done” machining from raw material to finished product, all without operator intervention. This is as true for simple parts such as plumbing fittings, as it is for highly complex parts used in motor vehicles and home appliances.

Not your Old School Transfer Machines

Popular misconceptions stem from memories of older transfer machine technology that was dedicated to producing a single part, required a lot of time and labor to make adjustments or part change-overs, and performed each machining operation in a linear sequence that resulted in long production times.

However, modern rotary technology has improved greatly. According to Mark Walker, industry veteran and president of Gosiger High Volume, “Modern CNC rotary transfer machines are highly flexible, provide quick change-overs within part families, and simultaneously perform multiple operations on as many as three sides of a part, thus significantly reducing cycle times.”

Moreover, eliminating manual transfer of parts between a succession of stand-alone machine tools not only reduces labor expense, but it also increases throughput while eliminating the quality problems associated with manually moving parts from one fixture to another. “This reduced part handling cost, plus consistent part quality with less scrap or rework, yields a much lower cost per part, which makes users (of transfer machines) far more competitive,” Mr. Walker says.

The Process

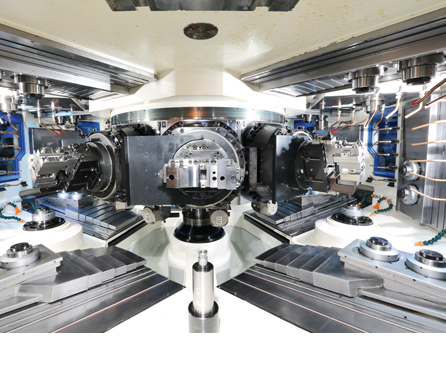

As the name implies, rotary transfer machines are based on a circular table that rotates either vertically or horizontally. A number of workpieces are clamped into positions on the table’s surface.

The number of parts loaded on a particular machine depends on the number of stations available to perform machining operations. Gosiger High Volume sells BTB CNC rotary transfer machines that, depending on the model, accommodate from four to 16 parts on a table.

If there are eight clamping positions on the table, the first position is used for loading and the other seven positions can each perform multiple operations on a part. As the table rotates incrementally, each part moves to another workstation where machining operations are performed on as many as three sides of the part.

The operations at each station happen simultaneously, which means that all seven parts on the table are being machined at the same time. Therefore, as many as 21 tools (parts in seven stations are each being machined on three sides) are working on these parts. The combination of automated part feeding and simultaneous machining operations is why a rotary transfer machine can produce an abundance of parts quickly.

For maximum efficiency, the various operations should be split across all available positions on the rotary table. The overall cycle time then is determined by how long it takes to complete the slowest operation. Thus, if the longest operation takes 10 seconds, that becomes the total cycle time.

The CNC “brains” of modern rotary transfer machines ensure that every movement is precisely controlled for consistency and accuracy, while making it easy to modify programs to accommodate changes in specifications or the addition of new members to a parts family.

Making Parts from Barstock

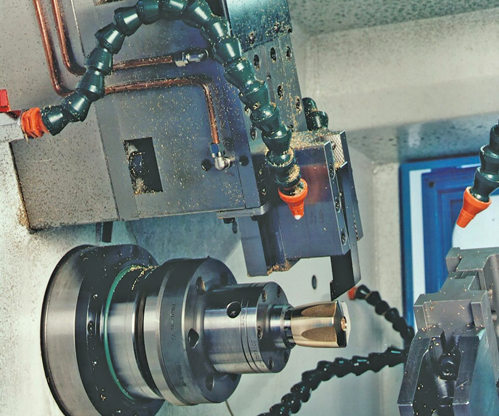

A different type of CNC rotary transfer machine is a version that enables machining of non-rotating steel, brass or aluminum barstock rather than discrete workpieces. The multi-spindle system uses an integrated bar loader to automatically feed the barstock that can be round, hexagonal, extruded or have a special profile. This makes it an excellent alternative to multi-spindle lathes or screw machines for high-volume applications.

The machine provides one-part clamping of the barstock so it can machine both sides of the bar blank. This saves time and eliminates the potential for repositioning errors that can occur in conventional lathes that machine one side of the workpiece and then rotate or relocate the part to machine the other side.

BTB bar transfer machines have 360-degree rotating chucks that allow for machining five sides of a workpiece and 1-degree chuck rotations to achieve specially angled machining operations. Rotating jaws allow machining of four sides of a workpiece without any external control.

What about Part Quality?

Replacing multiple machine tools with a CNC rotary transfer machine also provides better control over product quality. Moving a workpiece from one machine to another to perform a series of operations means taking the part out of one machining environment and into another that includes different fixtures and machine characteristics.

Such refixturing can also introduce the opportunity for human error, which can lead to difficulties holding dimensional tolerances, achieving required surface finish and preventing workpiece damage when moving from one machine to another.

While performing all of the required operations on a multifunction machining center eliminates many of these issues, to achieve volumes of 1 million parts per year or more will require 15 to 20 of these machine tools. Each of these machines—even if all are the same brand—has its own unique characteristics, and each requires a dedicated set of fixtures.

Since each machine is different, setting up a production run requires carefully tweaking the programming of each machine tool to ensure consistent results that reduce the possibility of variances in part quality. A CNC rotary transfer machine, on the other hand, sets up and manages all phases of production from one control station using a single part program.

Improved Workflow

In addition to taking up less floor space than multiple machine tools, rotary transfer machines simplify workflow as raw material is loaded at one end and finished product emerges at the other, without operator intervention or movement of workpieces in between.

“We all know that every touch of a workpiece interrupts workflow, adds cost to the part and opens the door for human error that can impact quality,” Mr. Walker says. “By minimizing operator involvement and smoothing workflow, CNC rotary transfer machines allow users to successfully compete against manufacturers who use cheaper labor. This is one of the reasons companies who were having parts made offshore are bringing that work back to the U.S.”

Justifying the Investment

Regarding the cost of rotary transfer compared with machining centers, Mr. Walker offers this perspective: “If a manufacturer produces at least 1 million parts per year, whether an individual part number or a family of parts, a CNC rotary transfer machine will reduce the cost of each part significantly, as opposed to using individual machine tools.”

Mr. Walker says although the initial investment of $1 million to $3 million for a CNC rotary transfer machine may be daunting, the payback for high volume producers is not only realized from the lower cost per part, but also from reduced capital investment in individual machine tools and labor costs.

“Consider a not uncommon scenario in which one CNC rotary transfer machine does the work of a dozen stand-alone machining centers. If each of those machines has a price tag of $250,000, you’ve already spent $3 million, not to mention taking up more floor space than does a single rotary transfer machine. If you add robots to load and unload all of the machining centers, you drive your capital expenditure even higher,” Mr. Walker says.

“Add to these costs the expense of having six machine operators tend those 12 machine tools over three shifts. That amounts to 18 operators working a total of 144 labor hours per day. In contrast, one operator per shift, or 24 labor hours, is all you need to oversee a rotary transfer machine for the same period,” he says.

Other Purchase Considerations

The true cost of owning any production machine goes well beyond the price tag. This is particularly true of sophisticated equipment such as a CNC rotary transfer machine. That’s why it’s important to consider a number of factors beyond the initial cost and specifications.

Does the brand have a solid reputation for robustness and reliability? Suppliers should be willing to provide references from existing customers. As said in an old Packard advertising slogan, “Ask the man who owns one.”

Are replacement parts readily available? All machines, no matter how well built, require periodic maintenance. If the machine doesn’t have readily available parts, or if they must be ordered from outside the country, there could be considerable downtime. Make sure the people who sell the equipment also maintain a substantial spare parts inventory.

What kind of technical service and customer support is available? It’s critical that the supplier has a local service and support staff, not simply a sales office with all other personnel located outside the U.S. There should be someone customers can call to ask technical or service-related questions as well as someone close by to make a service call when needed.

Is training included in the purchase price? If not, what will it cost to get operators up to speed? If training is included, how convenient and thorough will it be, and is future training readily available for new hires?

According to Mr. Walker, “If the essence of lean manufacturing is to eliminate any activities from the process that don’t contribute to customer value, CNC rotary transfer machines could be the poster child for that concept. That’s why if high-volume manufacturers are serious about achieving true one-and-done production, they should consider the lower cost-per-part advantages of CNC rotary transfer machines.”

Related Content

Moen’s Flowing Success with Rotary Transfer Technology

The popular faucet manufacturer has adopted new CNC rotary transfer equipment to produce valves for its new generation of Widespread faucets.

Read MoreCNC Rotary Transfer Machine Offers AI-Learning, Chipbreaking

Hydromat’s Force CNC Rotary Transfer Machine comes equipped with Force 50/150 tool spindle units, which are FANUC-controlled and offer advanced technology for AI-learning and chipbreaking functions.

Read MoreIndependent Turning Cell Enables High Concentricity Precision

PMTS 2023: The RV 10 Flexmaster rotary transfer machine’s precision turning cell (PTC) is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations.

Read MoreHigh-Production Multitasking Becoming More Flexible

Rotary transfer machines remain well-suited for high-volume production, but are now more accommodating to smaller batch sizes.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More