Breathe Easier With Oil Smoke And Mist Filtration System

Removal of the smoke and mist created by machining oils results in a cleaner plant and a healthier working environment for employees.

If the system you have in place for extracting oil smoke or mist from your shop air isn't doing the job, you may want to consider an oil smoke and mist filtration system from Sweden that the manufacturer claims is 99.9 percent effective in trapping airborne particles as small as 0.3 micrometers in diameter. Oil extracted from the air can be recovered and recycled. In most cases, the unit returns the filtered air directly to the shop, reducing energy costs and making for more balanced ventilation. Is "too-frequent" maintenance a problem with your existing system? This new system reportedly can go for up to 5 years without a filter change.

Called the Absolent system and available in the United States from Industrial Air Quality, Inc. (IAQ) (Youngsville, North Carolina), a number of basic vertical units are combined to create a filter sized to the customer's plant requirements. For example, the ODR 9000 oil smoke filter model shown, which can filter shop air at rates up to 7,050 cfm, is made up of three filter units operating in parallel.

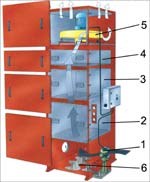

Each unit is a three-stage filter. The figure on the opposite page shows the major components of the filter and the flow of air through the unit. Here's how it works: First, contaminated air is sucked into the inlet (1) in the bottom section of the assembled unit and passes through the first pre-filter (2) where most of the oil particles are trapped. The pre-filter becomes saturated with the oil, which drains into a collection tray and is pumped into a return oil tank (6). The air proceeds through a second pre-filter (3) where any remaining large particles are filtered. Finally, the air is drawn through a third-stage HEPA filter (4) that traps anything larger in diameter than 0.3 micrometer. The top-mounted fan (5) draws oil-laden air through the filter and typically returns the clean air back to the plant or vents it to the outside.

Pressure gages for reading the pressure drop across the filter are standard with the unit as are lifting lugs. Options include an external fan (in place of the individual fans for each filter unit, as shown in the Figure 2), a fan control, a pump for pumping oil collected in the return-oil tank, a pump control, duct connections and more. This illustration shows the major components of the basic filtration unit and the air flow.

An efficient oil smoke/mist air filtration system can eliminate a number of problems at once. Oil smoke causes slippery floors and traps dust on machines and walls. It also can coat ventilation ducts, creating a potential fire risk. Removal of the smoke and mist created by machining oils results in a cleaner plant and a healthier working environment for employees.

The separating efficiency of the Absolent filter remains constant and does not deteriorate over time. The time between servicing is years long, making for low maintenance costs. The unit's pre-filters are self-draining and require little or no attention and facilitate continuous operation.

Absolent's ODR oil smoke filter can be assembled from basic units to satisfy any area or whole-plant air-filtration requirement. In addition to oil smoke filters, the company offers ODF oil mist filters for machining facilities using high-pressure coolant and its TSF dust filter units.

Although the oil smoke and oil mist filters have been available in the United States for only a few years, IAQ reports brisk sales, particularly in the automotive industry. Customers include Hyundai and Honda plants in the United States (European customers include Volvo and Rolls Royce). Non-automotive U.S. customers include a Robert Bosch Corp. plant in Charleston, South Carolina, which purchased several oil smoke and oil mist filters. The units reportedly proved highly effective in collecting small oil particles produced in machining operations combining high-pressure cutting fluid and high spindle rpm.

Related Content

Overcoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

Read MoreParts Cleaning Sector Shifts Energy Toward Regulatory Changes

With changes in EPA regulations regarding the use of some popular cleaning fluids, cleaning suppliers and end users are readjusting business strategies and/or cleaning processes to meet new requirements.

Read MoreA ‘Clean’ Agenda Offers Unique Presentations in Chicago

The 2024 Parts Cleaning Conference, co-located with the International Manufacturing Technology Show, includes presentations by several speakers who are new to the conference and topics that have not been covered in past editions of this event.

Read MoreKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More