Ceramic Inserts Can Boost Turning Productivity

When applied correctly, ceramic inserts can dramatically increase cutting speeds, providing shorter cycle times and cost savings compared to carbide for turning operations.

Ceramic inserts can be used to turn a range of materials. This non-coated IS8 grade from Iscar is designed for lightly to heavily interrupted cutting of cast iron for both roughing and finishing. It is said to offer high resistance to wear and thermal shock with good toughness. Photo Credit: Iscar

Carbide inserts are the most commonly used solution for many turning applications because they offer good performance at a reasonable price. However, ceramic inserts are worth considering as an alternative in some turning applications.

Ceramic is an advanced cutting material that, relative to carbide, is harder and enables machining at higher cutting speeds, but is suitable for only specific applications and workpiece materials.

Although ceramic inserts cost about two to three times more per cutting edge when compared to carbide inserts, the benefits are substantial in some applications and provide cost savings by reducing cycle times.

Advantages and Types

Made from aluminum oxide (Al2O3) or silicon nitride (Si3N4), ceramic inserts provide an advantage over regular carbide inserts. While a typical carbide grade has a hardness of 1,300-1,800 HV, ceramic grades have a hardness of about 2,100-2,500 HV (about 40% harder). Ceramic also has chemical stability in high temperatures as well as low temperatures. And with low thermal conductivity, most of the heat is transferred to the chip, not to the cutting tool.

.png;maxWidth=720)

Different types of ceramic inserts offer variations in color, composition and prove to be useful for different applications. Photo Credit: Eric Spencer

Ceramic inserts are divided into several sub-types. These types vary in color, composition and prove to be more useful in different applications. Ceramics provide excellent performance when machining hardened steel, cast iron and nickel-based alloys. Here are cutting recommendations for those materials.

Hardened steel. With coated carbide inserts, it is possible to machine steel up to a hardness of about 45 HRC if a low cutting speed of no more than 300 SFM is maintained. With ceramics, however, the cutting speed and machine material can be doubled, up to a material hardness of 60 HRC.

Using CBN inserts is another common solution for turning hardened steel. CBN can run faster than ceramic inserts and machine steel up to 70 HRC. But they are four times more expensive than ceramic inserts. Ceramic inserts offer a balance between price and performance for turning hardened steel in the 45 to 55 HRC range.

|

Cutting Speed with Carbide |

320 – 160 SFM (Up to 45 HRC) |

|

Cutting Speed with Ceramics |

660 – 330 SFM (Up to 60 HRC) |

|

Productivity Gain |

+100% |

|

Recommended Ceramic Type |

Black and Mixed |

Cast iron. Cast iron parts are primarily found in high volume production, where cycle time is critical. Ceramics can run at 2,600 SFM while cutting cast iron and can reduce the cycle time by 40-60%

|

Cutting Speed with Carbide |

1,000 – 600 SFM |

|

Cutting Speed with Ceramics |

2,600 – 1,300 SFM |

|

Productivity Gain |

+150% |

|

Recommended Ceramic Type |

Silicon Nitride, White and Black |

Nickel-based superalloys. Many nickel-based parts are used in jet engine components. Some of these components are large and can reach a diameter of 20 to 40 inches. The combination of the size with the slow speeds (around 150 SFM) yields long cycle times. It is not uncommon that a single part is machined over several days. Therefore, the fact that ceramic inserts can run up to six times faster makes them a popular solution in this industry.

|

Cutting Speed with Carbide |

200 – 60 SFM |

|

Cutting Speed with Ceramics |

1,300 – 500 SFM |

|

Productivity Gain |

+500% |

|

Recommended Ceramic Type |

Sialon |

Tips for Machining

The extra hardness of the ceramic material, however, results in extreme brittleness characteristics. Therefore, if proper guidelines are not followed, ceramic inserts can break. On the other hand, when mastering the proper techniques, machine shops can achieve a dramatic reduction in cycle time and maintain a safe process. Edge preparation, overall stability and chamfers at entry points are three key factors to consider when machining with ceramic inserts.

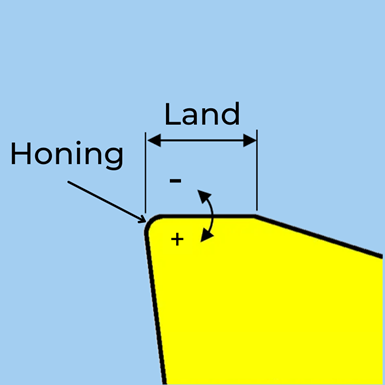

Edge preparation. Edge preparation is the term referring to the micro-geometry of the cutting edge. This tiny area stretching between 0.0005 inch to 0.008 inch has an important effect on the performance of cutting tools. In ceramic cutting materials (and CBN) it becomes a critical factor.

When an application involves heavy interrupted cuts, a wide K-land with a negative angle should be used. For a smooth continuous workpiece, honing might be enough. Photo Credit: Eric Spencer

When turning with ceramic inserts, it is important to match the edge preparation per a specific application. Therefore, a reputable supplier of ceramic inserts will have several edge preparations for each geometry in its catalog.

The edge preparation is composed of three parameters: land angle (zero or negative), land width, and honing size. The larger each parameter is, the stronger the cutting edge becomes. When an application involves heavy interrupted cuts, a wide K-land with a negative angle should be used. For smooth, continuous cutting, honing might be enough.

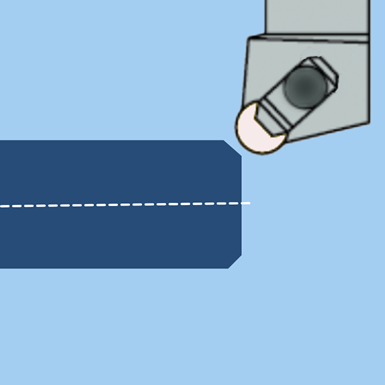

Entering the workpiece on a sharp corner can break a ceramic insert. Therefore, cutting a chamfer with a carbide insert is advised, and then the ceramic insert can enter into the chamfer. Photo Credit: Eric Spencer

Overall stability. Stability is crucial when turning with ceramic inserts. Every measure possible should be taken to increase it, which includes firm tool clamping, short overhang and good workpiece support.

Chamfers at entry points. A carbide insert should be used to prepare a chamfer on the end of the workpiece. Then, the cut should be entered with the ceramic insert. Entering the workpiece on a sharp corner can break a ceramic insert.

Eric Spencer is the founder of machiningdoctor.com, an online machining technical hub.

Related Content

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MoreData Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreRead Next

Measuring the Merit of Ceramic Cutters

In testing new ceramic microtools, a precision dynamometer ensures that cutting forces are measured precisely so tool performance parameters can be determined.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More

.png;maxWidth=300;quality=90)