Cobots Are Coming to the Precision-Turned Parts Industry

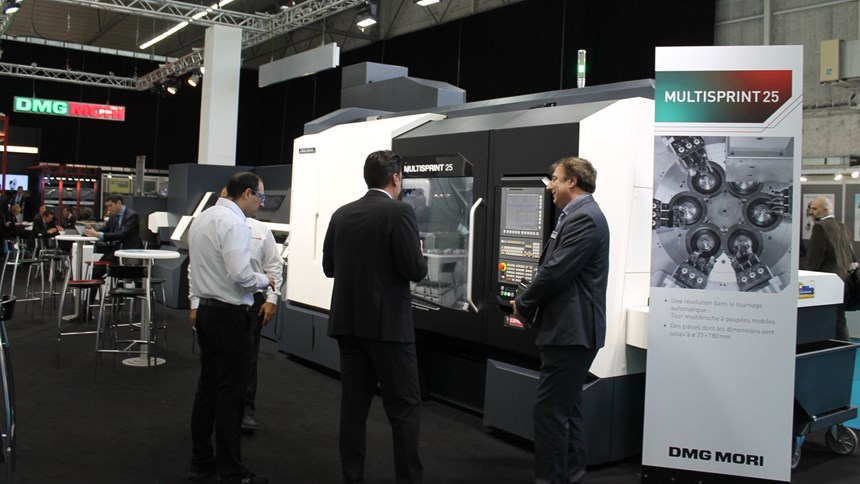

The international bar turning machine tool show, Simodec 2018, held March 6-9 in La Roche-Sur-Foron, France, focused on man-machine interaction, connected machining, Industry 4.0 and automation, robotics and particularly cobotics.

Simodec 2018, the international bar turning machine tool show located in La Roche-Sur-Foron, France, came at the right time. Held from March 6-9, the busy halls that hosted more than 300 exhibitors were buzzing, reflecting the healthy state of the French precision-turned parts industry. According to the French association, SNDEC (Syndicat National due Décolletage), turnover increased by 5 percent in 2017 compared with 2016, and the association expects similar growth figures when comparing 2017 with 2018.

Created in 1954, Simodec reflects the dynamic nature and high performance of the Rhône-Alpes Auvergne region, France’s top mechanical region, in particular, the “Technical Valley” in the Arve Valley between Chamonix and Geneva. This houses more than 800 small and medium-sized industrial companies in mechanical and bar turning subcontracting.

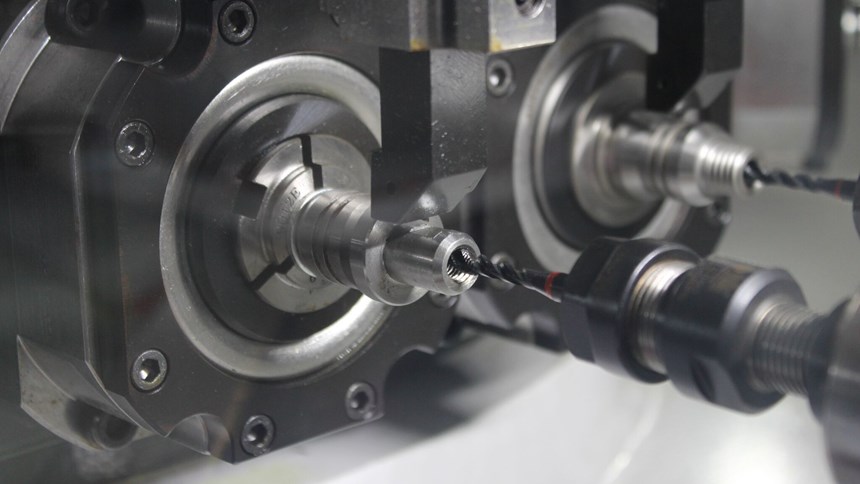

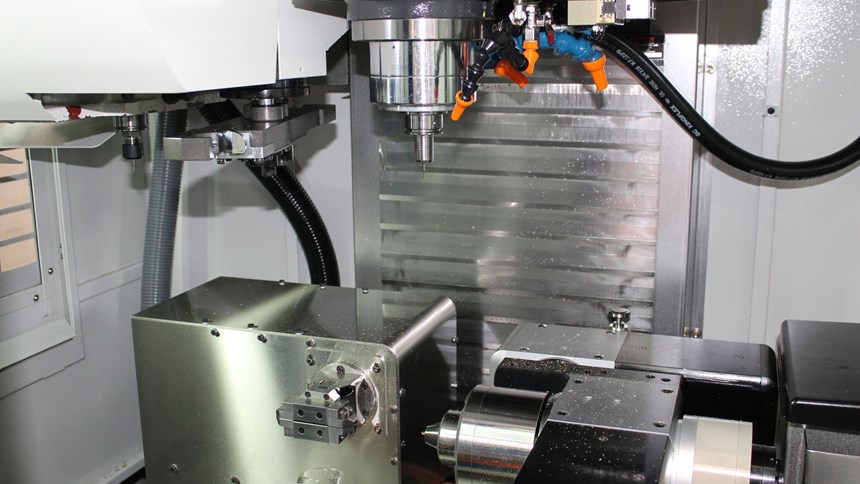

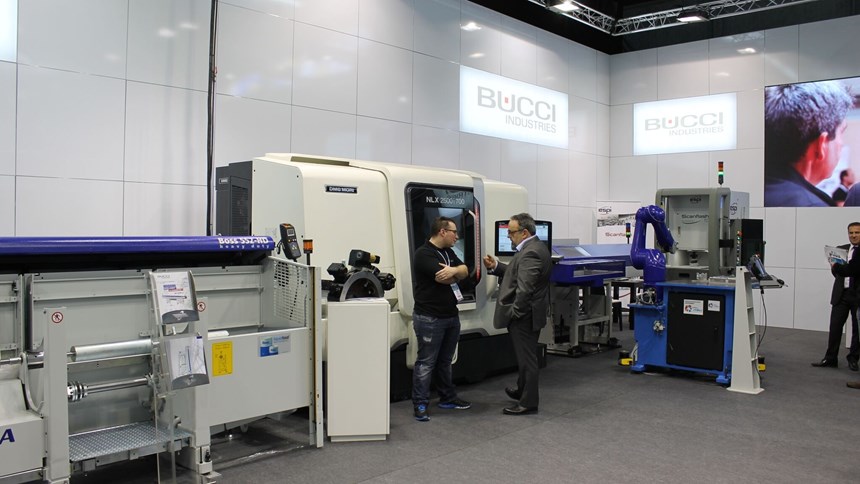

Themed “The Human at the Heart of the Industry,” this year’s show focused on people, recruitment and education, but also on man-machine interaction, connected machining, Industry 4.0 and automation, robotics and particularly cobotics. The industry is experiencing a rapid increase in quantity and capability of robots on shop floors. By integrating them into existing production environments, robots directly collaborate with humans, becoming a crucial part of the team.

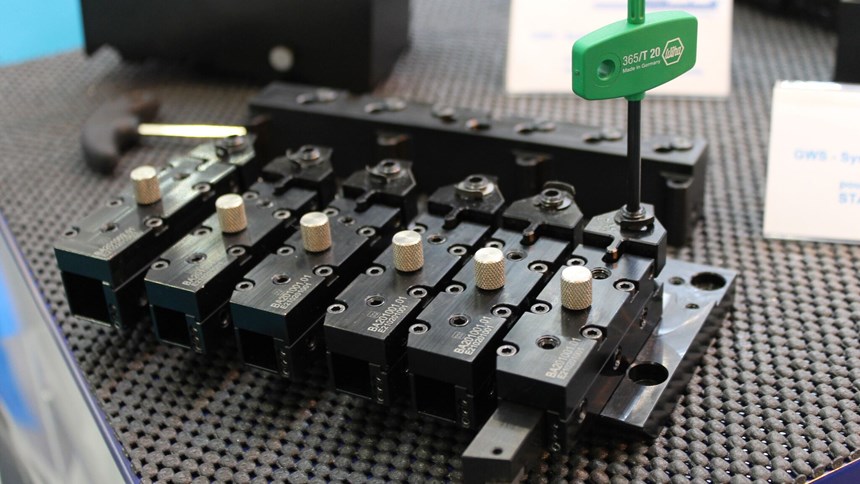

Click through the slideshow to see the many robots, cobots, and automation solutions on show, as well as the latest bar turning machines, multi-spindles and rotary transfer machines.

Related Content

-

Reinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

-

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

.jpg;maxWidth=300;quality=90)