Czech Out This New CNC Multi-Spindle

A new CNC multi-spindle is available in the U.S. for the first time. Manufactured in the Czech Republic, it has a long pedigree in Europe, but has been reletively unknown here--until now.

Through the years we have reported how the application of CNC to the venerable multi-spindle platform has changed the production process usually associated with this class of machine tool. Everybody knows that automatic multi-spindles are best applied to high volume/low mix applications. Many shops built their business using cam-driven machines that could effectively be set up to run a job for months and sometimes years.

That’s much less true in today’s industrial marketplace where the work available to run on these machines is increasingly complex, lower volume/ higher mix runs. This reality has opened the door for CNC multi-spindle builders to develop and sell machine tools that can profitably process parts that fit this new reality.

It is this environment that caused industry veteran Olaf Tessarzyk to step into the breech by offering the ZPS line of CNC multi-spindles to the North American market for the first time. Under the name ZPS America LLC, the Indianapolis-based headquarters will sell and service its line of ZPS CNC multi-spindles. “Over the last 5 years, high-precision, relatively high-volume parts production is increasingly being handled by CNC multi-spindle machines, which can offer shops the advantages of quick cycle times, the precision of single-spindle turning centers and rapid change-over to handle a range of complex parts, “ Mr. Tessarzyk says.

Of course, the elephant in the room is the recession during which many businesses “go to ground.” However, there are some forward-looking shops that continue to invest in machines to more efficiently process work despite the economic conditions and be in a better competitive position when we emerge from this morass. One such shop is highlighted in the accompanying sidebar “Somebody Has to be First.”

What is ZPS?

ZPS is the CNC brand of multi-spindles built by Milan, Italy-based parent company TAJMAC (pronounced “TIE-mock”). Formed after World War II, TAJMAC is a multinational group of machine tool building, distribution and sourcing companies. Its manufacturing arm for the line is ZPS (a Czech acronym that translates to Precision Engineering Plants), a century-old machine builder located near Zlin in the Czech Republic.

While most multi-spindle users in the United States haven’t yet heard of the company’s CNC brand, it has successfully installed multi-spindles throughout Europe since the 1980s. Some other TAJMAC brands that have had North American exposure include Wickman, Euroturn and Manurhin K’MX as well as private labeled machines made for well-known U.S. and Japanese builders.

The point is that although the ZPS CNC brand is new to most shops in the United States, its multi-spindle and machine tool roots are planted deep. And while many of you are less familiar with ZPS, many of you may already own its machines under a different brand.

Changing Mind Sets

It’s a fair assessment that within too many multi-spindle and single-spindle machine shops there is a certain amount of inertia to rethink potential use of CNC multi-spindles in production. “The old ‘set it and forget it’ mentality dies hard. I have missionary work to do in this regard,” Mr. Tessarzyk says.

New generation CNC machines, like the ZPS, are not really designed to replace the old cam multi-spindles directly. Rather, they represent a new machine tool class that can enable willing shops to rethink traditional processes and practices with an objective eye on how to lower costs through improved productivity.

The concept of multi-spindle machining is as valid today as it was a century ago. Simply put, the ability to perform simultaneous cross-feed and end-feed cuts progressively on five, six or eight stations is still an excellent way to manufacture. The problem is, the parts now available for manufacture require much more capability than traditional multi-spindle machines can deliver.

This new reality has created an opportunity and a challenge for Mr. Tessarzyk and his ilk to help shops accept these new machines as multitasking production centers rather than multi-spindle turning centers and rethink how they process workpieces. The kind of parts that process well on these machines require much less turning and much more drilling, tapping, hobbing and milling operations than has been traditional. The end game for production is to drop quality parts complete with no secondary operations.

With the processing flexibility available in new generation CNC multi-spindles, Mr. Tessarzyk believes one potential market for the ZPS CNC multis is shops that are currently producing parts across turn-mill machines or multi-machine production cells. The CNC multi-spindle platform competes in both operational flexibility and quick change-over with these machines with the added advantage of higher volume production capacity to process more jobs in less time.

Under the Hood

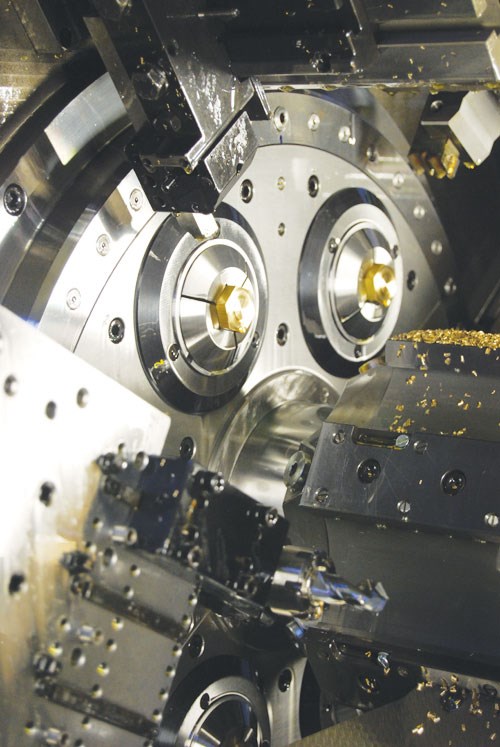

The first in the series from ZPS CNC is the TMZ 642. Equipped with dual Siemens 840D controls, this six-spindle multi can have as many as 72 discrete axes under full CNC control.

Some of the standard features include compound slides (X and Z axes) on each cross-slide station that can interpolate for single-point turning. The machine also can bring six tool carriers, each with driven tools, into the cut.

There are five backworking tools available; three of these tools are driven. While VDI toolholders are standard, Capto quick-change toolholders are available. To further expedite quick change-over, the machine’s tools can be preset off line.

Often on CNC multis, backworking operations, depending on their complexity, slow the overall cycle time. To help alleviate this, the machine’s cutoff tool station operates on a separate slide to expedite

backworking.

New Spin on Spindles

One of the most important differences between a CNC

multi and a traditional cam machine is the multi’s abil-

ity to program each main spindle independently. With this important feature, it is no longer necessary to compromise cutting data. Rather, each station can machine at the optimum feed and speed for the operation and provide ability to use each spindle as a full C axis.

The engineering challenge of independent spindle speeds is driving each spindle while allowing the spindle drum to index from station to station. Typically, this is accomplished by mounting direct drive servomotors on each spindle.

Of course, each of these motors has an umbilical—its power cables—which somehow must be accommodated as the spindle drum rotates. To date, the most common solutions to this problem are to rapidly reverse the drum at the end of each 360-degree rotation or use a slip ring connector to supply power so the drum indexes uni-directionally.

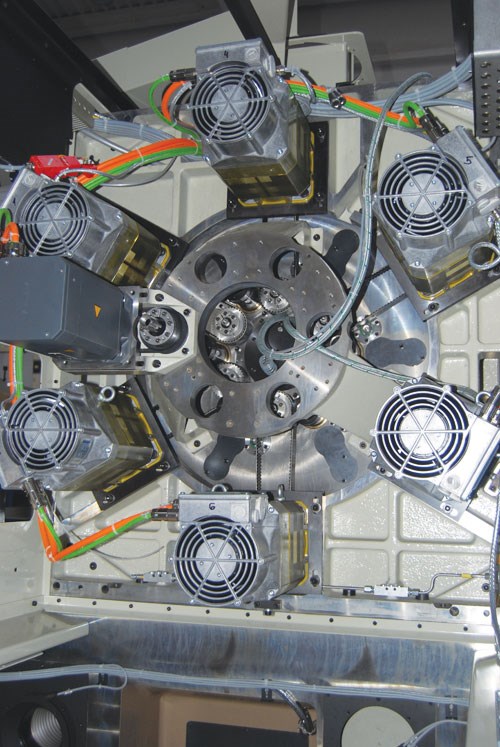

ZPS has come up with a unique approach to this problem. On its six-spindle model (TMZ 642), each spindle is driven by a 10.5 kW programmable motor. On its eight-spindle model (TMZ 867) introduced to the North American market at PMTS 2009 in May, each drive motor is rated as high as 30 kW.

Rather than use direct drive motors mounted on the headstock end of the machine, ZPS attaches its main spindle drive motors around the periphery of the tailstock end of the machine, outside the cutting zone. The motors are fixed and do not rotate with the drum, eliminating the power cable problem.

So with the drive motors bolted outside the endworking side of the machine, and the rotatable spindle drum and its spindles at the opposite end of the workzone, how does one transmit power to the six or eight spindles?

The ZPS design uses six or eight concentric drive shafts, which run through the hollow centerline of the center block, to transmit power from the drive motor to each spindle. The transmission setup uses belt idle shaft take-off from the drive motor, which connects by gear to one of the drive shafts.

At the spindle drum, a gear at the opposite end of the drive shaft engages its spindle. This geared drive system is constant mesh and allows the spindle drum unlimited, bi-directional indexability. Because the spindle drive motors are directly connected to the spindles, programmed speed changes from one station to the next can use the indexing time for free to accelerate or decelerate, saving cycle time.

According to Mr. Tessarzyk, removing the drive motors from the workzone eliminates a significant heat source. The ZPS spindle drum needs no inter-cooling system for thermal stability. Another benefit he cites is the ability to use conventional collet actuation systems that provide cam-machine-like (very strong) clamping forces because the units mount on the spindle shaft without interference from a direct drive motor. This also eliminates the need for a hydraulic system to be brought into the drum for clamping.

Torque is another benefit this drive system brings to the party. On the TMZ 642 for example, the drive motor is rated at 12,000 rpm, but is geared down, by virtue of the drive system design, to 6,000 rpm, effectively doubling the torque available at the spindle and thereby reducing the motor’s ramp-up time.

Is This for You?

These new CNC multi-spindles, ZPS and others, have evolved beyond their traditional root into very capable, flexible and highly productive production centers. Yes, they are expensive, but according to Mr. Tessarzyk, there is a relatively simple ratio that can be applied to the justification process.

Basically, he says, if a shop is running a job on three or more single spindles, the multi-spindle under con-sideration should be able to produce four times the volume of one of the single-spindle machines. That

represents a 4 to 1 ratio and, on average, is a good justifi-

cation starting point to consider a CNC multi-spindle.

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreCAM-Driven Lathe Questions

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

Read More5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)