Dressing Technique for Truing Up Diamond Grinding Wheels

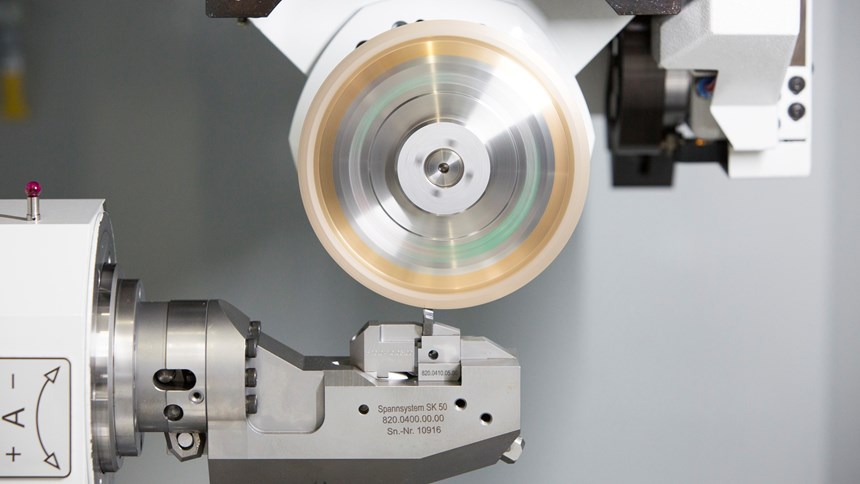

This tapered diamond grinding wheel dressing technique, which takes place inside the machine, is used in production of high-precision profile inserts.

It is not unusual for grinding wheels and dressing wheels to wear with use. Haas Multigrind LLC has encountered this issue with shops in several industries, including medical engineering, precision tool manufacturing, gear manufacturing, the aerospace industry, the energy industry, and particularly with those that manufacture profile inserts. To support their need for dimensional accuracy, these customers use Haas’ Multigrind CB, Multigrind CA, and Multigrind CU high-tech CNC grinding machines.

For carbide insert manufacturers, Haas uses diamond grinding wheels that must be dressed (a slight trimming process to bring a tool into correct geometric form) on a regular basis to ensure grinding results. If not dressed regularly, high rpm can cause grinding wheels to become misshapen, resulting in negative effects both on quality and productivity. Faced with the challenge of chasing geometry, 18 months ago Haas started developing a new dressing process called XING (short for “cross”) dressing.

The Truth about Truing Up

Each abrasive particle on a grinding wheel is a small cutting tool. “The XING dressing process is just one—although important—piece of the puzzle for producing high-precision, carbide inserts,” says David Drechsler, business development manager, North America at Haas Multigrind. “In order to grind carbide, we need to use a diamond abrasive wheel.”

Haas’ grinding machines often use the tapered or V-shaped diamond grinding wheel to machine profile inserts. These precise tapered diamond grinding wheels frequently feature an edge radius of a few hundredths of a millimeter and are correspondingly sensitive. “The geometry is very precise,” Mr. Drechsler says, “so we must produce and maintain a precise radius or precise geometry on that grinding wheel.”

When the edges of the grains of a grinding wheel (even one as hard as diamond) have been dulled, the grinding process can suffer. The grinding wheel does not cut as freely, thereby producing more heat in the grind zone. More important, the profile of the grinding wheel wears so that the geometry and precision of the workpiece suffers. Haas uses a silicon carbide or corundum wheel as the dressing tool for its tapered diamond grinding wheels.

This sharpening process, known as truing or dressing, returns a wheel to its original profile shape and performance characteristics by cleaning away clogged areas between the diamond grains and by restoring the original profile, or cross-sectional shape, on the wheel’s edge.

Dressing with Profile Accuracy

“Traditionally, a dressing wheel spindle axis is parallel to the grinding wheel spindle axis, and we interpolate the profile on the wheel,” Mr. Drechsler says. “But then the dressing wheel wears so it’s no longer the profile that we think it is. So what we’ve done is turned that dressing spindle 90 degrees, now perpendicular to the grinding spindle.”

This positioning of the dresser wheel axis at a 90-degree angle is the XING dressing technique. “For diamond wheel dressing, the dressing wheel still wears as much as or more than the grinding wheel, but now the dressing wheel is always a perfect radius,” Mr. Drechsler says. “So that eliminates one of the huge variables in that process.”

With the NC-controlled process, the profile of the grinding wheel can be generated with the circumference of the dresser wheel. This maintains a consistent contact surface and pressure between dresser wheel and grinding wheel. A lower pressure load and higher profile accuracy for the grinding wheel are other benefits of XING dressing.

Dressing without Unclamping and Re-Chucking

Like all other dressing techniques at Haas, XING dressing is also carried out inside the grinding machine, so there’s no need to unclamp and re-chuck the grinding wheel. This setup has a positive effect on dimensional accuracy, while the grinding wheel boasts better radial and axial runout, making it possible to generate better surfaces.

In current projects, the technique has been applied to profile grinding wheels, grinding pencils or quills, and grinding wheels with other grain types, as well as ceramic and hybrid-bonded grinding wheels. As a result, many different wheel contours can be dressed using the Multigrind grinding machines.

This level of flexibility is only possible, however, if the option for direct or indirect wheel probing is available. A noise sensing system is always required for setting up, optimizing and operating the dressing process. When it comes to V-shaped wheels with a 30-degree included angle, the wear is highly dependent on previous wheel damage, meaning the existing wear behavior needs to be measured and compensated for.

Customers Demand Quality and Efficiency

The regular and proper dressing of the grinding wheel is important to both reestablish a precise geometry and to create optimal grinding wheel topography. Customers demand this precision, surface quality and efficiency, and Haas responded by expanding the XING dressing technique for use in additional applications.

“In the cutting tool world, this is a really strong point for Haas,” Mr. Drechsler says. “There are a lot of people who make tool and cutter grinders, but we have a strength in the formed insert niche. So we’re continuing to develop and advance the technology required: the wheel, wheel dressing, programming, and workholding.”

Considering Haas’ CNC grinding machines can be found in manufacturing facilities all over the world and are used in almost every industry that processes metal, it is important to keep them in top form.

For more information from Haas Multigrind LLC, call 574-268-0053 or visit haas-schleifmaschinen.de/en/.

Related Content

Studer S100 Grinding Machine For High-Precision, Flexible, Reliable Grinding

The machine is well suited for a wide range of internal, surface and external grinding applications, making it well suited for the entry-level market.

Read MoreWhat is CNC Peel Grinding?

It resembles single-point turning on a lathe because, similar to a lathe’s tool, the grinding wheel moves in the X and Z axes to grind contours, diameters and other features.

Read MoreTooth Flank Grinding Technology Minimizes EV Drive Noise

Drives for electric vehicles require gear components with tight tolerances and excellent surface finishes. Even minimal ripples in the surface of tooth flanks on shafts and gears can cause interference noise in drive performance.

Read MoreCarbon Fiber Spindles Aim to Eliminate Grinding Variance

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More