Precision machining manufacturers in the Northeast are gearing up for the area’s biggest manufacturing event at Eastec 2023, which is set for May 16-18 in West Springfield, Massachusetts. This event is a great opportunity to do in-person research on the latest technology and trends that can strengthen your business.

For our May Technology Showcase, we’re focused on products that will be spotlighted at Eastec. This preview includes a form tool system for producing individual tools in very small series; an electronic bore gage for flexible measurement; a monitoring and control system for reducing cycle times; and much more.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Click on each link below to read the full product post:

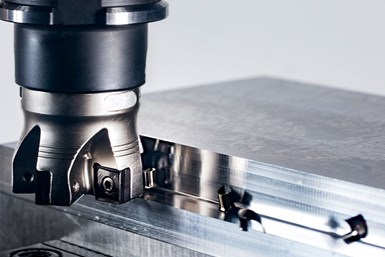

Schwanog manufactures custom insertable and solid carbide form tools made to order per customers’ part prints. Applications include grooving, drilling, milling and threading. These tools, which are manufactured in the United States, can reduce cycle times by as much as 40%, the company says. Tools are ground individually according to customer specifications, and can hold a tolerance of as low as ±0.01 mm.

Photo Credit: Sunnen Products Co.

Sunnen Products Co.’s PGE-6000 Electronic Bore Gage enables precise control of final bore size and quality of purchased or semifinished parts, with an instant digital or numerical readout. The electronically amplified comparative bore gage is said to be well suited for quick, simple, economical process control in almost any manufacturing environment. An onboard computer can store serialized part measurement data for use in Statistical Process Control (SPC) analysis.

Ceratizit’s ToolScope and KOMtronic U-axis systems, as well as its line of indexable milling tools and range of Klenk solid-carbide drills are designed to improve machining efficiency. The Ceratizit ToolScope monitoring and control system consists of a suite of specialized modules — process control, machine protection, digitization and documentation — aimed at measuring and optimizing particular aspects of machining operations.

Photo Credit: Tsugami America

Tsugami America, the exclusive North American importer of Precision Tsugami Machine Tools, offers the BW129Z Swiss-type independent-gang slide lathe which is a chucker-convertible, high-performance machine tool with a FANUC 31i-B control. The BW129Z uses its three-path control system and dual independent-gang slides to reduce cycle time and produce complex parts quickly.

Cosen Saws’ V-1822 Tilt-Frame Band Saw is said to deliver exceptional quality for both everyday use to help automate workflows or serve as a small band saw to keep in the shop for one-off cuts. The V-1822 takes Cosen’s tilt-frame design and applies it to a rigid, yet small, footprint with an 18" × 22" capacity. Developed to be a more affordable option for those in nonproduction settings, the saw features a manual design and enables miter cuts ranging from 0 to 60 degrees in both directions.

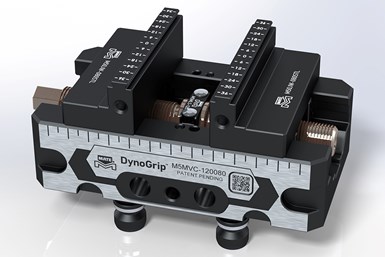

Photo Credit: Mate Precision Technologies

Mate Precision Technologies’ 52/96 workholding system is engineered to maximize holding power for 3-, 4- and 5-axis machining centers. The company says the system reduces setup times and process variability, while providing accuracy and repeatability in a compact, quick-change, modular design. The system is also compatible with similar 52- and 96-mm, four-post pull stud configurations from Lang, Jergens, 5th Axis, Gerardi and more.

Photo Credit: Platinum Tooling

Platinum Tooling is the North American importer of REV motorized broaching tools. REV S.R.L., located in northern Italy, is the manufacturer of broaching solutions for CNC live tool lathes. These tools are well suited for machining simple keyways or internal and external profiles, both teeth and splines. The company says it is possible to achieve many common profiles, including square and hexagon as well as custom profiles when required. Depending on the material, keyways can be machined up to 16 mm.

Photo Credit: SMW Autoblok Corp.

SMW Autoblok Group, a designer and manufacturer of premium workholding solutions for the industrial market, offers a MillTec circular magnetic chuck for precision five-axis machining. With MillTec, the workpiece is clamped from the base without any obstacles to the tool such as brackets, making it is easier to carry out complex operations with five-sided access to the part, including complete profiling and undercut working, as well as creating through holes and pockets.

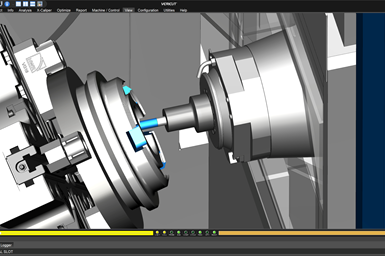

CGTech’s Vericut simulation, verification and optimization software is capable of simulating multiple types of machining operations such as traditional milling and turning to additive or hybrid manufacturing, as well as composites. Vericut detects errors and potential collisions in NC programs prior to running them on machines for the first time, so programmers can send programs to a machine with the confidence they’ll run without incident.

Photo Credit: Mitutoyo America Corp.

Mitutoyo America Corp.’s LH-600F Linear Height Measurement System is the latest model in the Mitutoyo Linear Height Gage line. It has several new features, including a high-accuracy scale unit and guiding mechanism. The LH-600F now features a touchscreen interface that is designed for easy and intuitive operation, enabling users to measure with the press of a button or through touchscreen icons.