It’s time to reunite with the precision machining industry at the Precision Machining Technology Show (PMTS) 2023 set for April 18-20, 2023, in Cleveland, Ohio, at the Huntington Convention Center. It’s the perfect place to look for new ways to make your business more efficient and productive. PMTS brings a broad range of technologies together all in one place to make your research time more effective.

Production Machining wants to help kick off your research with a series of PMTS Product Previews. In this group, we’re taking a look at measurement solutions, including handheld digital microscopes that offer fast frame rates and high image quality; portable CMM arm for measuring complex tools; a compact, self-centering bore alignment system; and more.

Before you go to the show, don’t miss PMTS show highlights in Derek Korn’s PMTS feature article and look for more PMTS Product Previews each week until the show! And don’t forget to register for the show.

For all the latest PMTS product highlights, please visit our extensive PMTS Preview Section which includes new PMTS products posted every weekday up through the show’s opening day.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining’s free monthly print magazine.

Click on each link below to read the full product post:

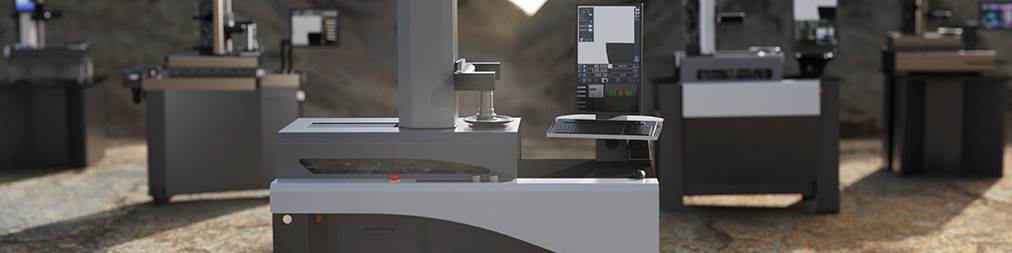

Renishaw says its Equator is a low-cost option for high-speed, comparative-gaging inspection of manufactured parts developed and proven on the shop floor in collaboration with industry-leading companies in the automotive, aerospace and medical sectors. Based on an easily scalable and adaptable “parallel kinematic” structure, Equator's principle enables high-speed scanning and rapid moves between features, while retaining stiffness that delivers point to point repeatability, critical for accurate gaging, the company says.

Dino-Lite’s handheld, digital microscopes now offer both USB 2.0 and USB 3.0 options. The company says the hardware and software deliver fast frame rates without sacrificing image quality. USB 3.0 uses a transfer mode called “SuperSpeed” capable of transferring data up to 5 Gbits/s (625 MB/s). With this improved speed comes improved quality. Dino-Lite models with USB 3.0 enable an increase in smooth high-quality imaging up to 45 FPS at 1280 × 960 resolution. SuperSpeed enables users to take advantage of the full power of the Edge Series optics, including improved color accuracy and image quality.

Photo Credit: Faro Technologies

Faro Technologies’ Quantum Max ScanArm with laser line probes (LLPs) is said to capture all the measurements of complex tools with speed and accuracy. The unit combines the measurement capabilities of a Quantum Max FaroArm portable coordinate measuring machine (CMM) with the noncontact functionality of an LLP. The Quantum Max offers three LLPs that optimize accuracy, speed or a blend of both, depending on the project need. Whichever LLP users choose, 3D ScanArms capture precise measurements in nearly any environment, from the factory floor to the field.

Photo Credit: General Inspection

General Inspection’s VisionLab 3D measuring system can handle versatile applications, including first-piece inspection, SPC sampling, final audits or 100% inspection using pick-and-place automation to streamline inspection processes. It can all be accomplished in a fraction of the time compared to manual gauges. The system measures all profile characteristics. The company says it is the only true 3-dimensional gauging system that provides complete part measurements in less than 7 seconds.

Photo Credit: Hamar Laser Instruments

Hamar Laser Instruments’ L-703B Self-Centering Bore Alignment System is an upgraded system that uses the variant of Hamar Laser’s compact and versatile L-703 Laser. The company says this system makes bore alignment easier and up to 75% faster than competing systems. It replaces the L-705 Laser for applications where the laser is mounted externally. The system is smaller and lighter than the L-705, and works with Hamar Laser’s self-centering targets that require only one measurement per bore.

Photo Credit: Lyndex-Nikken

Lyndex-Nikken/Elbo Controlli Tool Presetters are said to combine the best of both worlds for thermal stability and optical precision. The combination provides the highest level of repeatability and reproducibility making Elbo Controlli Presetters well suited for most tool measuring and inspecting applications. The Tool Presetters incorporate custom optical scales and vision systems that are geared for measuring and inspecting cutting tools. They measure tools offline which optimizes spindle uptime.

MSI Viking’s advanced metrology services include accredited 9001:2015 and ISO/IEC 17025 calibration and inspection services as well as engineering services and support for CMMs. Its Midwest and Southeast inspection facilities, equipment, practices and personnel are audited annually to maintain the ISO/IEC 17025 accreditation needed in today’s advanced technological environment. With fully equipped and accredited labs, it is able take on projects large and small, whether it be a first article inspection or picking up the overflow from regular operations.

Omega TMM says its entry-level, table-top EVO is the most well-optioned presetter of its size on the market. Using the latest software and mechanical technologies, the EVO is the easiest, most accurate entry-level machine, targeted to any industry. The presetter standard features include a cast iron construction, a 10.5" touchscreen and a match-ground, 50-taper spindle. It also has an integrated spindle brake, LED surface inspection light and a new and improved EVO control system with new software.

Photo Credit: Six Sigma Concepts

Six Sigma Concepts’ InGage Discovery is an automated video metrology system designed to give quick and accurate measurement feedback for turned and molded parts. The Discovery immediately inspects the backlit shadow profile of parts manually or automatically placed within its view. Its InGage control software enables quality engineers and machine operators to quickly analyze parts. Inspection data is displayed, stored and sent for process control in any manufacturing or lab environment.

.jpg;maxWidth=300;quality=90)