Efficient High-Speed Roughing

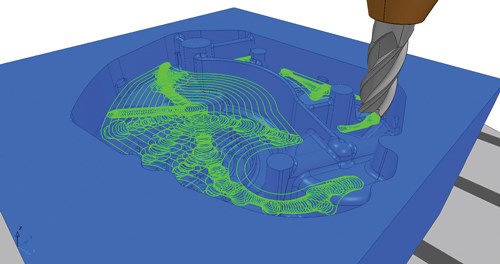

The Vortex roughing strategy produces tool paths with a controlled engagement angle for the complete operation.

Efficiency is key to getting the most from any machining process. Conventional roughing strategies, though, typically only achieve the optimum cutting conditions during a straight-line cut. Any internal corners within the model significantly increase the engagement angle of the cutter. To protect the cutter, this increase needs to be balanced by setting a lower feed rate. The user then has the choice of using this lower rate over the whole tool path, which increases the machining time, or varying the feeds and speeds as the cutter moves around the model, and so increasing wear on the cutter.

The Vortex strategy, developed by Delcam, produces tool paths with a controlled engagement angle for the complete operation. This technology has been developed specifically to gain the maximum benefit from solid carbide tooling, in particular those designs that can give deeper cuts by using the full flute length as the cutting surface. It can be used for two- and three-axis roughing, three-plus-two-axis area clearance and for rest machining based on stock models or reference tool paths.

Like other Delcam roughing strategies, Vortex tool paths are calculated to provide efficient machining by following the shape of the part and by keeping air moves to a minimum. This method is particularly important for rest machining operations.

Positive Results

The benefits of using the Vortex strategy will vary depending on a number of factors, including the material and shape being cut and the machine tool and cutting tools being used. A series of trials run by the company on a variety of machine tools within its Advanced Manufacturing facility has shown time savings often surpassing 40 percent, with the cycle time for one sample part being reduced from 121 minutes to 34 minutes (71-percent savings).

Other examples include a reduction of 67 percent when cutting a number of pockets in a stainless steel part, a 63-percent time savings on a titanium part, and a 58-percent savings when cutting an aluminum component.

Unlike other high-speed roughing techniques that aim to maintain a constant theoretical metal removal rate, the Vortex strategy produces tool paths with a controlled engagement angle for the complete operation. This maintains the optimum cutting conditions for the entire tool path that would normally be possible only for the straight-line moves. As a result, the cutting time is shorter, while cutting is undertaken at a more consistent volume-removal rate and feed rate, thus protecting the machine.

Extended Tool Life

Because Vortex tool paths have a controlled engagement angle, tools should never be overloaded, thus achieving the maximum tool life. Shock loading caused by changes in the contact angle is minimized, preventing chipping of the flutes. In addition, the stability of the cutting conditions gives consistent edge temperatures, prolonging the life of the tool coating and preventing heat damage to the surface of the part. Finally, the ability to use stepdowns of as much as two or even three times the tool diameter spreads the tool wear evenly over the cutting surface of the tool, again contributing to longer tool life.

Vortex is fully integrated with PowerMill’s step-cutting strategy for area clearance. This approach minimizes the terracing that can result from using a large stepdown by moving back up the part after generating the initial area clearance program and generating automatically extra tool paths to remove additional material at intermediate slices. It optimizes the amount of material that can be removed with a single tool, while helping to maintain a more consistent removal rate by increasing the feed rate for the intermediate slices.

“Anyone using the Vortex strategy will be able to hear the difference immediately,” says Mark Forth, product manager for Delcam’s Advanced Manufacturing Solutions. “Conventional roughing produces a sound of varying pitch, which indicates that the optimum cutting conditions are not being used and could even be a sign of tool overload or chatter. In contrast, Vortex roughing gives a constant pitch, showing that the tool is operating under consistent conditions. Users will also be able to see the difference in the regular size and thickness of the chips produced, providing further evidence of the consistency of the cut.”

Related Content

Mastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.

Read MoreMastercam Software Improves Programming Flexibility

IMTS 2024: Mastercam introduces Mastercam 2025, with features including Mastercam Deburr for automated edge finishing, finish passes, mill-turn support for Y-axis turning and automatic license update notifications.

Read MorePrecision Machining Technology Review: December 2024

Production Machining’s December 2024 technology showcase includes some of the latest technology from Hexagon, Kennametal, SmartCAM, Horn and SMW Autoblok.

Read MoreHexagon AI-Powered CAM Software Streamlines Part Programming

The ProPlanAI CAM programming tool is designed to help machine shops achieve operational excellence at scale.

Read MoreRead Next

Software Speeds Prototype Production

Using Delcam’s PowerMill and PowerShape software enabled a prototype manufacturer to turn CAD data into a validation part in less than 24 hours.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More