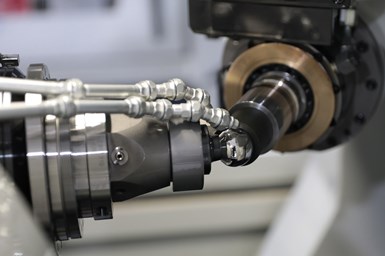

After grinding, a honing operation improves surface finish before a final buffing operation. An automatic wheel measurement process helps ensure that each honing operation starts from the correct infeed position.

Photo Credit: ANCA

Medical industry experts estimate that orthopedic hip surgeries will increase at a rate of 5% year-to-year until 2026. This is no surprise, given the growing aged population around the world. With this trend, an increased demand for devices and components to support these procedures as well as equipment to produce them will emerge. One example is the ANCA machining process for femoral ball grinding, developed jointly with grinding wheel manufacturer Tyrolit. This process is said to deliver quality and consistency in the finished femoral ball, using specialized machine control and technology on the ANCA MX7 Linear CNC grinding machine.

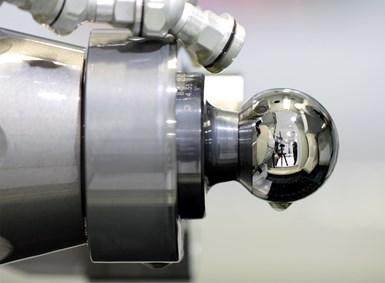

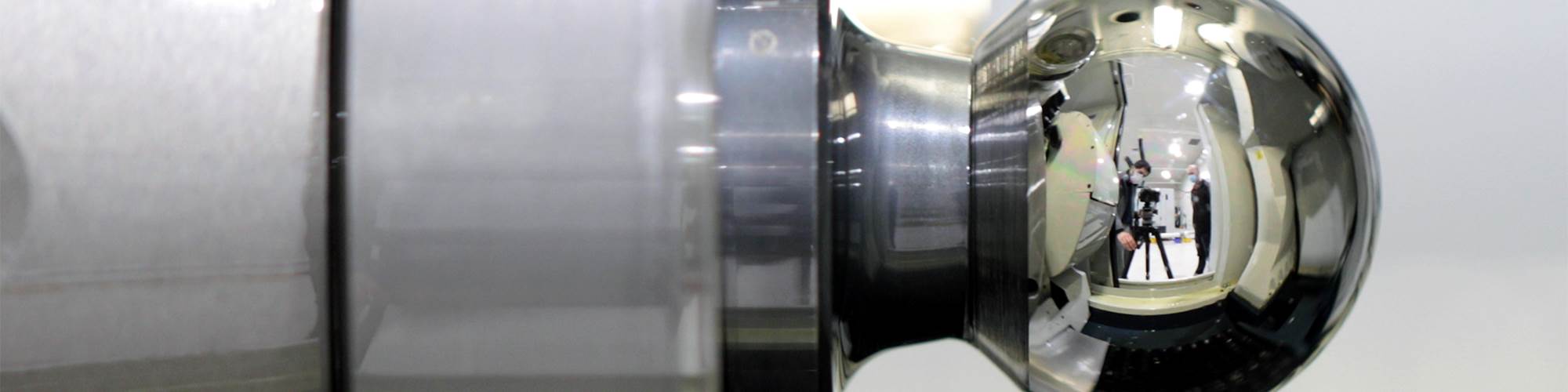

Effective performance of femoral balls used in hip replacement implants demands consistency of roundness, size and surface finish. To achieve this, ANCA has developed a process on its MX7 Linear machine that applies a series of sequential grinding, honing and final buffing operations in the same work envelope. The result is a surface finish on the ball of less than 0.01-micron Ra and part roundness of less than 3 microns.

The first step in the process is grinding the initial part accurately to size. Using plated CBN grinding wheels, excess material is removed from the rough turned part. This operation makes upstream processes easier by relaxing the tolerance demands for the part during grinding.

Next are a series of fine honing processes that produce incremental improvement in the surface finish. Application engineers from ANCA and Tyrolit combined to develop a process that delivers stable production results on the femoral ball.

The surface finish of finished balls is less than 0.01-micron Ra.

Although Tyrolit wheels have been specifically developed for the femoral ball applications, wear naturally occurs during the production process. According to ANCA, it was well positioned to meet this challenge as it is the designer and manufacturer of its own LinX linear motors as well as the CNC and servo drive system that control the machine and grinding wheel movement. ANCA system engineers developed a new control algorithm for this application which enables an operator to program the desired forces applied by the honing wheel on the femoral ball. With this programmed force, the wheel feeds into the ball at a constant rate as it wears. The three different Tyrolit wheels being used can be programmed with their own unique grinding force parameter to achieve a mirror surface finish and consistent part size tolerance.

A final buffing operation delivers a mirror finish on the working surface of the femoral ball. Photo Credit: ANCA

Additionally, an automatic wheel measurement process was developed to help ensure that each honing operation starts from the correct infeed position. This is said to deliver process consistency regardless of the wheel wear after each honing operation.

A final buffing operation is the last step, creating a mirror finish on the working surface of the ball. This is critical for ensuring mechanical friction and wear are minimized in the final hip implant.

The surface finish of finished balls is less than 0.01-micron Ra. Photo Credit: ANCA

The surface finish of finished balls is less than 0.01-micron Ra. Photo Credit: ANCAThe ANCA MX7 Linear has a six-wheel pack changer that enables all the grinding, honing and buffing operations to be performed in one setup. In addition, the tooling used for femoral ball production can be easily changed for cutting tool manufacturing applications. As a result, rather than purchasing a dedicated machine for femoral ball production, manufacturers can use their machine for other CNC grinding applications that complement their market and business model. For example, grinding of surgical rotary cutters, drills and reamers as well as femoral hip rasps are all possible on the same MX7 Linear machine.

Related Content

Lissmac Grinding Machine Provides Versatile Surface Finishing Performance

The EBSC grinding machine is capable of processing both tri-dimensional and flat parts, allowing for broader applications across various industries.

Read MoreEmag Grinding Solutions Provide Precise Gear-Profile Grinding

The G 160 and G 250 gear-profile grinding machines provide short chip-to-chip times, intelligent axis concepts as well as thermal and mechanical stability.

Read MoreShould You Bring Tool Regrinding In-House?

In some situations, the potentially high investment in an in-house tool grinding process can be justified with a relatively fast ROI. (Includes video.)

Read MoreStuder S100 Grinding Machine For High-Precision, Flexible, Reliable Grinding

The machine is well suited for a wide range of internal, surface and external grinding applications, making it well suited for the entry-level market.

Read MoreRead Next

10 Tips to Get the Most Out of a Grinding Machine

Following these 10 steps can help grinding shops produce high-quality tools, increase productivity, reduce breakdowns and extend machine life.

Read MorePreparing Tool Grinding Machines for IoT

Internet of Things (IoT) doesn’t require scrapping existing tool grinding machines, but investing in new technology, such as communication networks and automation, is necessary.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)