Evaluating Shop Management Systems

Organized shop processes, thorough knowledge of potential system capabilities and careful planning by the right company personnel are keys to acquiring the most suitable shop management system.

Selecting the right shop management system for a shop can be a challenging task. Most manufacturing companies today that are looking for a solution are on their second or third generation system. Some are using many different applications, such as Excel, Word, Access and other databases, along with an off-the-shelf accounting package, to assemble the pieces of a shop management system that works for them.

The bar has been raised when it comes to shop management solutions. Companies are no longer merely enamored with the fact that these systems exist. They are looking for integrated solutions where they can use the majority of the functionality. People are tired of purchasing these expensive systems, taking the time to implement them and then ending up using only about 25 percent of the capabilities.

Before choosing a system, a shop needs to think carefully about the conditions of the existing shop processes and what will be required from the system to streamline the business.

Organized Processes

If a shop’s current business processes are a mess, a new shop management system will be very difficult to implement and may only compound the existing problems. Functions such as estimating, quoting and order entry should be structured with consistent methodology, and jobs should be tracked from beginning to end. Often, shops use many different applications for these functions, and if the applications are not linked to allow communication between them, there is a risk of redundancy.

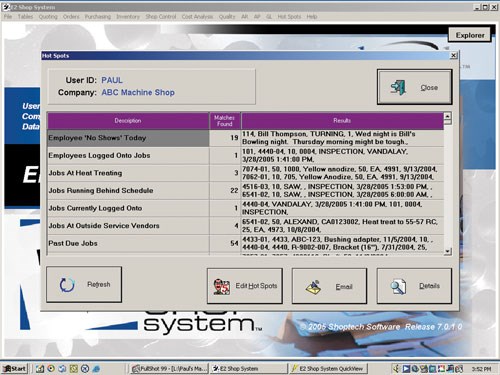

Personnel should have quick access to a list of open jobs and active customers. Billing should be up to date. When a job ships out, the invoice should follow closely behind. This link from manufacturing to front office operations is a key to accurate job costing. The same is true with purchasing. Purchase orders, receiving and billing must be accurately matched.

It is good to examine the business processes and consider changing them before selecting a new shop management system. Each existing process should be studied to be sure it is truly needed and if improvements can be made. Opportunities for growth and improvement will surely be missed if current processes are simply automated without re-evaluating their effectiveness.

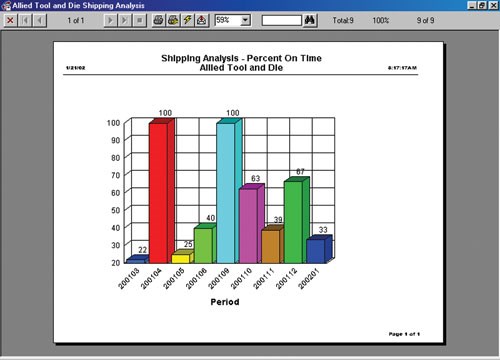

A good place to start is by establishing a clear set of goals and objectives. The shop should know what problems it can resolve now and what it is looking for the new software to correct. Examples might include resolving scheduling concerns, establishing accurate job costing, improving on-time delivery, integrating sales and production, and developing a thorough accounting system. However, the goals need to be realistic. It takes time, planning and an understanding that a new shop management system is not a magic wand that is going to solve every problem.

It is unlikely that any given software product will do 100 percent of what a shop is looking for, so once the desired features and functional requirements of the software are identified, the shop should look to address at least 90 percent of the issues. The key is finding the system that best fits the type of business while not spending too much time trying to find the “perfect” system. Some systems are more suited for screw machine houses. Others might be better for a fabricating environment. There are many highly capable systems in the manufacturing world, but only a select few will fit the specific needs of any given shop.

Within 60 to 90 days of using the new software, the company should be able to do basic operations such as entering orders, shipping and billing. Estimating, scheduling and data collection might be further down the road. Just getting the system up and running allows the shop to see some results in terms of time savings and then be able to justify implementing the next steps.

Shopfloor Knowledge

The shop floor is the heart of the business, and that’s where it should be determined what functionality is needed from the shop management system. Better information coming off the shop floor will help everyone in the office make better business decisions in a more timely fashion. Getting more profitable work in the shop is the name of the game, and the key is accurate job costing. A busy shop floor does not necessarily translate into higher profit margins. The shop must be busy with the most profitable jobs possible.

Accurate costing will get back to the estimators so they can clearly see what jobs were successful and which ones were poor performers. They will then know not to accept the same bad job down the road. A real-time bar coding system on the floor, for example, can eliminate a lot of guesswork by allowing estimators to obtain an accurate job history. It can help them identify areas of miscalculation and where they need to re-evaluate the manufacture of particular items from an engineering standpoint.

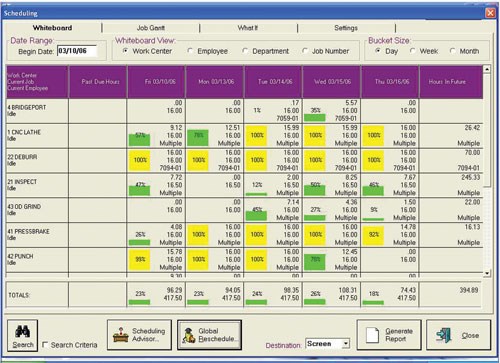

Throughput, scheduling and reduction of labor for a given job are what shop management personnel look to address most. They want to try to get as many jobs through the shop as possible to reduce the number of days in-house, from the time an order comes in to the time the job ships. With the right data, the shop can easily analyze which jobs perform best under the given criteria.

Shops are busy, but typically they spend the majority of their time on the jobs with the lowest profit margin. This type of work can bog a shop down, keeping it from capitalizing on the profitable jobs. A suitable shop management system can provide accurate costing, even broken down by types of work, so a shop can determine what types of jobs to take in the future based on which ones bring in the most profit.

Evaluation Team

Because of their direct relationship to the profitability of the company, the shop management personnel are the most critical players in selecting the new system. They are the ones who make the decisions on how to efficiently get more jobs through the shop. What happens on the shop floor is what determines profitability, but it is not uncommon for the knowledge accumulated there to take a back seat to the business decisions of the financial and IT personnel. The shop foreman, purchasing manager and estimators, though, must be involved in the decision.

Yes, the IT department (or consultants performing this function) can play a big part in determining what hardware or network is needed to run the system. The IT department should also be concerned with the tools that were used in developing the new system. They will have the best knowledge about whether the system under consideration is up to date using the latest tools and if it is a mainstream package. They will have a good idea of whether the software will be around and manageable down the road and if training will be readily available. But IT will not be familiar with the direct implications of the features and functionality on the shop floor, and therefore, should not drive the decision of which solution is the best fit.

The moral of the story is to look at the big picture in what the new system can do for the business. It is only human nature for the people involved within a company to be concerned solely with how the new system will affect their own job. But in the long run, it is the people who make the biggest difference in the company who should determine the direction.

Software Demonstration

Before making a purchasing decision about the system, a shop should make sure that the software vendor takes the company’s shop-specific data through the software. While a demonstration with sample data can provide a good overview of the capabilities of the system, it does not show how it will actually perform on the job. The demonstration needs to be geared toward solving the shop’s specific needs, with real customer data.

That’s not to say that the customer should take control of entering the data during the demonstration. The software is complex enough that, without training, the customer may not be able to make a reasonable judgement as to its effectiveness. But if the customer’s job information, purchasing information and scheduling requirements are plugged in by a trained operator and analysis from the software is effectively presented to him, he can then see whether the software can help. The sales person should ask as many questions about the requirements of the shop as the shop is asking about the software.

An integrated system that brings all elements of shop management together is modular by nature. As such, it is important that the entire system was developed and tested in-house by the vendor. A shop management system with a core developed by the vendor, and an array of bolt-on modules contributed by external sources can lead to confusing and inconsistent operational methods. From one level of functionality to the next, the software should have the same look and feel and architecture as the original, core package. The modules, then, become an advantage to the buyer, providing the option to purchase only the necessary functionality, with the opportunity to add on later with little or no learning curve to contend with.

Closing The Deal

After seeing the software demonstration, it’s time to check the references. It is always nice to visit other shops on-site to see how they are using the system. But more importantly, it is imperative to talk to people who are in the exact same industry, doing the same type of work. It makes little sense for a buyer to visit a mold shop down the street if a screw machine shop identical to his is easily accessible over the phone.

The vendor should supply a detailed quote of what the customer will receive and what options are available. Each module should be listed with its matching price, giving the customer the opportunity to purchase only what he or she needs. Other modules can be added down the road when the shop is ready to implement them.

Implementing the right manufacturing software can significantly improve a company’s use of available information, as well as increase productivity and profits. As long as a shop has organized and efficient processes, the appropriate people in line for software evaluation, and the opportunity to use real data in testing to solve specific problems, a well-suited shop management system should be within reach.

Related Content

Avoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read MoreERP Software Enables Manufacturers to Maximize Operational Efficiencies

PMTS 2023: JobBoss2 from ECI Software Solutions assists manufacturers with decision-making and reveals opportunities for growth and cost savings.

Read MoreShopGuru Software Supports Organized CNC Machine Operations

IMTS 2024: ShopGuru’s digital work instruction software offers a robust, secure solution that can enhance machining efficiency and accuracy.

Read MorePaperless Parts' AI-Powered Automation Tool Streamlines Quoting

Wingman is powered by a secure AI model developed to extract critical information from quote packages so that estimators can work faster, automate administrative aspects of setting up quotes and minimize the risk of missing important details.

Read MoreRead Next

Shop Management Software Helps All The Shop's Managers

Here’s a case where free shop management software proved so valuable to a company that it purchased three more seats of it in a short amount of time.

Read MoreChanging Shop Management Software Takes Teamwork

Manufacturer’s hardware platform and shop software upgrades bring added flexibility, simplicity and speed to the network and its processes.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)