Fast ROI Convinces Shop to Add Robotic Automation

“If we get a job that requires a process we don’t normally do, we have very few other shops in the area we can call on, so we figure out how to do it ourselves. This often means adding new technology,” says Cody Dolce, owner of Glacier Tool & Die.

Stevensville, Montana, is not exactly a hotbed of manufacturing. In fact, Glacier Tool & Die is one of only a handful of manufacturing facilities in the area. That’s why family owners, Gary, Peggy and Cody Dolce, continue to add capabilities to their shop. As Cody explains, “If we get a job that requires a process we don’t normally do, we have very few other shops in the area we can call on, so we figure out how to do it ourselves. This often means adding new technology.”

Recently, the company won a defense contract to make the trigger/hammer assembly for the M16. The contract was for 65,000 pieces, with the possibility that the order could increase in volume. Within the first year, the order increased to 485,000 pieces.

A Well Rounded Shop

It is opportunities like these that make Glacier unique, and it’s the reason the company does fine blanking, surface grinding, turning, deburring and even wire EDM. In fact, for many years, the company had the only wire EDM in the state. Those aren’t the capabilities one typically expects to find in a 15-person shop.

In business since 1980, Glacier co-founder, Gary Dolce, was an early adopter of CNC machining, and when he learned that the U.S. government was looking for defense contractors to make parts for the M16 rifle, he decided to go after a contract. He bought an AR-15 rifle (the non-military predecessor to the M16), dismantled it and decided which parts he could make. He won the contract, and Glacier instantly evolved from a tool and die shop into a CNC production facility.

Pump up the Volume

Although Glacier Tool had built a number of custom fixtures, and production was running smoothly for the trigger/hammer assembly for the M16, the increased demand from his customer concerned Cody. “The additional volume placed a heavy demand on the equipment and our employees. It required two dedicated VMCs and three employees over two shifts,” Cody says. “I quickly realized we needed to find a way to meet production demands, make it easier on the operators and reduce the overall cost per part.”

That’s when they decided to explore automating the process with a FANUC robot they previously purchased, but had yet to use. “After we bought the robot, we couldn’t find anyone locally who could integrate it for us, so it never came off the skid. Knowing that we had a solid order for these parts through 2019, Glacier decided to take another look at automation. That’s when the staff contacted Okuma dealer Hartwig Inc., and it recommended an upgrade to an Okuma Genos M-460 CNC vertical machining center that had the performance specs needed and could be tended by the robot. Hartwig explained that Gosiger Automation was the systems integrator for all U.S. Okuma dealers and would work with the company to design an automated loading and unloading system.

Automation Integration

“Gosiger was willing to integrate the robot and a Flexomation part feeder that we also owned into the system,” Peggy says. “Other companies we talked to didn’t want to use our existing equipment. It also helped that Gosiger is an Okuma distributor and authorized FANUC integration partner, so they already knew the machine tool, robot and operating system, which made integrating the robot much easier.”

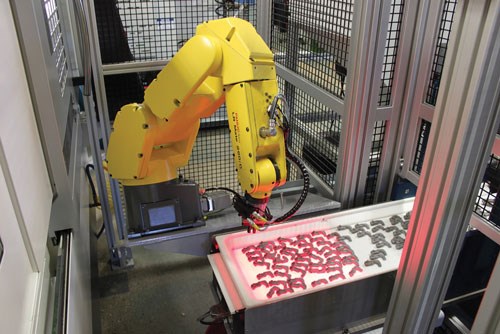

Gosiger Automation’s solution was to mount the six-axis industrial robot onto a fabricated steel base positioned to the side of the machine door, so it can reach around to load and unload parts. Equipped with iR-vison, the robot identifies and picks acceptably oriented parts from the feeder and corrects for radial orientation to enable fixture loading.

In operation, parts are loaded into the system in bulk where the machine vision system is used to eliminate the need for parts to be precisely located for robotic handling. The parts are placed into fixtures designed and built by Cody at Glacier Tool & Die, with input from Gosiger Automation that ensured they were automation-friendly.

In each machine cycle, there are three sequential part machining operations performed. The robot indexes the parts through the nests, loading a blank and unloading a finished part after each machine cycle, and depositing the finished parts onto a conveyor belt. Parts are handled efficiently by a Schunk component-based, dual-gripper, end of arm tool.

Seeing Results

When they originally bought the robot, Gary and Cody thought using it would be as easy as plug-and-play. Cody found out otherwise when he attended a robot programming workshop. “It’s not only a matter of telling the robot to do something; it also needs to communicate with the other parts of the cell. Gosiger Automation handled all of that, so we could get up to speed quickly. Our machine operator had never worked with a robot or an Okuma machine before, yet she quickly got the hang of it,” Cody says.

The system has made a huge improvement in Glacier’s productivity. It cranks out a part every 3 minutes with 16-second change out, never taking a break or a sick day. Now, instead of two VMCs, a day shift operator, night shift operator and two full-time inspectors, the company meets its daily quotas with the VMC, the robot and a part inspector. That also freed up two operators to work on other projects.

“With these cost savings, we’ll pay for the system in only 1.5 years,” Cody says. “That return on the investment made good financial sense for us and was possible in part by Gosiger Automation’s willingness to use our existing robot and feeder.”

Now, Glacier Tool & Die has added “automation” to its long list of “can dos” at this 15-person shop. Its accomplishments have paid off for the shop’s reputation and will earn it even more business down the road.

For more information from Glacier Tool & Die, visit glaciertool.com or call 406-777-5818.

Related Content

Reinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

Read MoreStarting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

Read MoreReplace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

Read MoreHigh-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)