For Plateau Honing, Consider Ball Style

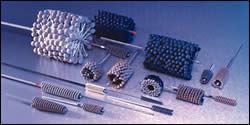

The ball-style hone is a specialized abrasive tool that is instantly recognizable by its unique appearance. For engineers in the automotive, aerospace, manufacturing and machining industries, this application-engineered hone, characterized by the small, abrasive globules that are permanently mounted to flexible filaments, is a flexible, low-cost tool for sophisticated surfacing, deburring and edge blending.

The ball-style hone is a specialized abrasive tool that is instantly recognizable by its unique appearance. For engineers in the automotive, aerospace, manufacturing and machining industries, this application-engineered hone, characterized by the small, abrasive globules that are permanently mounted to flexible filaments, is a flexible, low-cost tool for sophisticated surfacing, deburring and edge blending.

Plateau Honing

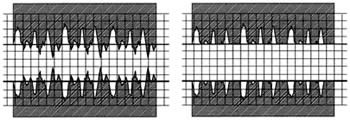

One example of such an application is “plateau” honing, a process by which cylinder walls are subjected to a bore-finishing procedure that increases the life of both the cylinders and the piston rings. The goal of plateau honing is to create a metalurgically stable microstructure on the wall of a cylinder bore. The process removes loose, cut, torn and folded material within the cylinder, created by grinding or boring. This amorphous zone typically consists of microscopic peaks and valleys. Flexible honing removes the peaks while leaving the valleys. The result is a more solid cylinder wall structure that can retain lubrication in the valleys—a critical benefit for improving start-up of a cylinder and piston by reducing metal-to-metal contact.

“The trouble you run into is that no two plateauing scenarios are alike,” explains Jim Huffman, director of engineering, Salem Tools Inc., a provider of engineered manufacturing industry products and value-added services in Salem, Virginia. “Frequently, there’s a finishing problem. The bore is either too smooth or too rough.” Engineering a ball-honing tool that is application-specific will significantly reduce problems like these.

Flexibility in Honing

Brush Research Manufacturing Co. (BRM) is a privately-held industrial brush maker in Los Angeles, California, that has been in business since 1958. Its Flex-Hone tool, a ball-style hone for which the company is best known, was originally designed for cylinder finishing, deburring and deglazing.

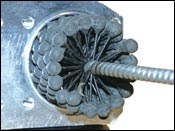

The tool’s design makes it especially useful for this original purpose as well as numerous other applications that call for the use of a resilient, flexible and soft-cutting honing solution. Its independently suspended, abrasive globules both self-center and self-align to the bore and self-compensate for wear, all of which facilitate close-tolerance finishing work.

The applications for which the ball-style hone is suitable range from very simple operations, such as golf club shaft finishing, to the complex finishing jobs common to machining and manufacturing. This versatility stems, in part, from the fact that the product is available with a range of abrasives and grits.

According to the company, this type of honing tool should not be viewed as a commodity, but as an engineered tool individually designed to yield maximum value in a specified application. Many criteria may be considered relative to the job-to-be-tackled—among them the size of the tool, the type of abrasive used and the grit/grade. It is for this reason that BRM custom designs tools to meet the specifications of customers.

Applied in Pistons

Total Seal Inc. (Phoenix, Arizona) is a manufacturer of performance piston rings staffed by racing and performance engine enthusiasts. The rings are subjected to rigorous testing, a process partly involving cylinder ball honing.

“We recommend the ball hone to our customers,” says Technical Manager Keith Jones. “There are over-the-counter hones available, but most are 120-grit silicon carbide, and that won’t work for everything. With the genuine article, you get a variety of media and precisely the grit you need.

“The object in honing is to achieve a prescribed set of roughness/finish numbers,” Mr. Jones explains. “For this purpose, the use of the right media and grit are essential. A failure to employ both in the case of engine cylinder wall finishing can detrimentally affect the operation of the engine. Should the cylinder surface end up too rough, too smooth or out of the range of recommended finish numbers, the pistons may not seat.”

Brake Applications

Miller Industrial Products Inc. (Jackson, Michigan) is an automotive industry job shop specializing in the machining of disc brake motors and brake drums for cars and trucks. “We’ve incorporated Flex-Hones into our brake machining operations,” says President/General Manager Bill Miller. “The machining of the inside of a brake drum must be very precise. You have to work to exact tolerances and custom-engineered hones to meet that requirement.”

The shop employs ball-style hones to resurface the inside of auto brake drums to create a non-directional surface finish and limit “brake hum,” which can be very annoying to motorists, Mr. Miller explains. In years past, this was accomplished with grinding, a tedious job entailing much effort and long man hours. Since that time, Mr. Miller has adapted the technology to do finishing work on brake rotors as well. At the moment, several machines are fitted with ball-style hones, a conversion facilitating the processing of many thousands of disc brake rotors per day.

Related Content

Overcoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

Read MoreIn-Machine Probing Possibilities for VTLs

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

Read MoreSimulated Complete Machining of EV Aluminum Inverter Cases

At EMO 2023 in Hannover, Germany, FANUC presented an automated manufacturing cell simulating the complete production and measurement of aluminum electric vehicle (EV) inverter cases.

Read MoreT&H Lemont Reaches Quality Assurance Milestone

The company’s quality management system has provided a solid year with no defects, rejects or recalls.

Read MoreRead Next

Expanding On Honing Options

While available both in horizontal designs and vertical designs, three different machining methods are used for honing operations. The most common method, effective on a range of diameters and materials, uses multistroke machines to hone with one or more abrasive stones attached to a single rotating spindle.

Read MoreFlexible Honing Tool Finishes Cylinder Cavities

Not much metal finishing equipment that is used in factory production setups is also readily available and applicable to situations where precision secondary finishing is also required in the field.

Read MoreDiverse Applications for Ball-Style Honing

A ball-style hone is a specialized abrasive tool that is characterized by small, abrasive globules that are permanently mounted to flexible filaments. It is designed to be a low-cost tool for sophisticated surfacing, deburring and edge blending.

Read More