From Setup to Final Pass: CNC Tool Management

Tech Brief

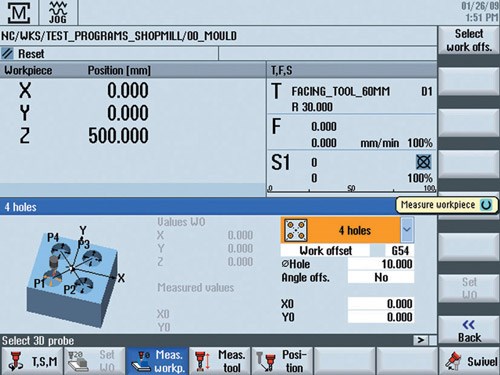

With today’s high-powered and graphic-intense CNC, operators have everything under control, all on one screen.

With today’s high-powered and graphic-intense CNC, operators have everything under control, all on one screen. In the “old days” (about 10 years ago), tool management was a challenge for even the most talented operators and programmers.

That’s because the sophistication of the internal CNC power had outdistanced the graphical capability of the information displays. When a tool was needed to redo a section, it might have taken several minutes to recall the program, find the right tool number, identify the proper path and redirect the operation. Over the course of even a relatively short run, this was a time problem and a frustrating situation for even the best operators.

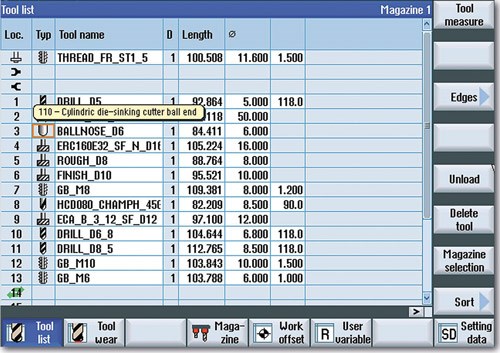

Today, tool management is much easier because of the significant advancements made in the operator interface on the high level CNC. The optimum conditions for tool management should include all the following and be accessible on a single screen: an intuitive program, so all tools would have an icon representation for quick identification; a well-arranged, easily viewable single screen presentation of the tool data with readable tool names, not only numbers, so a particular job could be identified; tool life tracking, with meaningful information on the proper change-over time; and simple load/unload functions for tool magazine allocation and sufficient memory to allow all of the tools on the most sophisticated machines to be monitored from a single file. End of tool life messaging should be automatic, as well.

A real helper for turning tools would also be having both the primary and secondary cutting edges indicated with quick access to full data records. In this way, process stability can be greatly enhanced with a quick viewing of a single screen, instead of switching from screen to screen.

There should also be a function onboard the CNC to allow a single button push to route a tool to the proper magazine location, plus an alert for manually placing a missing tool into a location during the cycle for uninterrupted machining. Otherwise, there is the need for having an automatic swap-out for a worn tool.

Whether an operator is using the scratch method or a tool measurement system during setup to determine the tool geometry, having that geometry automatically stored in the CNC tool offset memory is another desirable function.

The highest powered CNC gets a user nowhere, unless the operator can quickly and easily set up the part, shape a blank without extensive, additional programming and then manage the tools used in a most efficient manner.

We often get asked if the workpiece can be set up easily, regardless of the program’s length or detail. That day has also arrived, because today’s sophisticated CNC should allow users to simply trace an edge, corner or bore hole and then have the control determine the proper clamping position, including the workpiece’s basic rotation, even on sloping surfaces.

A workpiece can be face-milled or face-turned simply by setting the relevant parameters in setup mode. Then operators select cycle start and then begin cutting. The operator can also use this type of feature for one-touch boring of chuck jaws.

Best of all, every feature above should now be available in an affordably priced CNC.

Related Content

Lone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

Read MoreCAM Software’s Place Serving Emerging Trends

SolidCAM aims to align its product development and customer engagement strategies to address the evolving needs and challenges of the manufacturing industry.

Read MoreTech College Alum Returns to Teach CAD/CAM at Alma Mater

New part programming developments continue to be added to the Tri-County Technical College curriculum and solutions for Swiss-type lathes might soon be included.

Read MoreMastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.

Read MoreRead Next

Integrated Tool Management with CAD/CAM Connection

By enabling efficient management of tool data, measuring and inspection equipment, the company’s established software is said to optimize and standardize the entire process of tool preparation and production planning.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More