Selecting the Right Milling Tool for Any Machining Task

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.

Modern high-performance milling cutters combine high cutting data with long tool life and, consequently, contribute to an increase in the productivity of manufacturing processes and to a more favorable cost structure. However, certain factors must be considered when selecting tools, particularly in the case of flexible processes such as milling. For example, non-productive process times can be reduced by changing tools less often. In the case of small toolchangers, the ability to process different materials with a single tool may be of benefit. To maximize the potential of the machine tool, the user generally should choose between using a special tool or a universal tool.

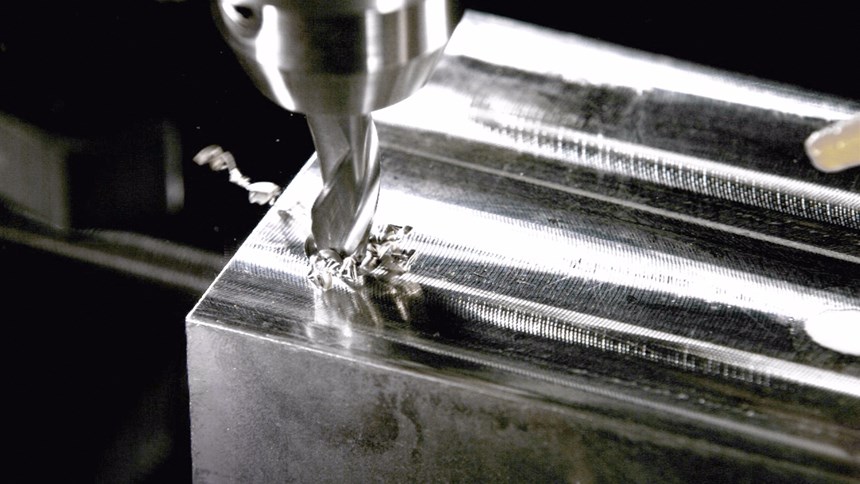

HPC milling cutters now have unequally spaced cutting edges and an uneven helical pitch because geometry is key to the performance of a milling cutter. This design ensures less vibration and contributes to smooth cutting action.

Milling Performance and Durability

During high-performance milling, tools should be designed for high process speeds and the resulting temperatures (which can promote premature tool wear). Such high temperatures also cause oxygen to become reactive, so coatings should be resistant to oxidation as well. The coating is supplemented by an optimized fine-grain substrate that increases both toughness and hardness simultaneously.

Edge preparation is also important. A homogenized, deliberately rounded-off cutting edge prevents the growth of cracks and chips, slows down wear and ensures slow and even abrasion. Milling cutters with these characteristics can be used for machining a variety of materials.

With these requirements in mind, the Hoffmann Group has designed its milling cutters from the Garant MasterSteel product line to complete various machining tasks, including side milling and milling of slots and ramps, helix milling and even drilling.

Side Milling and Slots

For users who primarily side mill components or mill slots, using universal machines with toolchangers to do so, conventional roughing end mills with four cutting edges work well. They can also undertake tasks that indexable insert tools are otherwise intended for, such as if the surface of the component also must be milled flat. The Garant MasterSteel HPC milling cutter eliminates the need to change tools and can reduce non-productive time and processing times when machining a general structural steel welded construction.

Full Slot Milling

A knuckle form roughing cutter works well for milling deeper, full slots with more than 1× diameter and for machining delicate components. Due to their knuckle form profile, these HPC milling cutters produce less cutting pressure and expose the component to less stress. The particularly short chip evacuation also increases process reliability.

Tools with a higher number of teeth increase process efficiency. Milling cutters with five teeth are particularly efficient if the feed per tooth can remain the same during the manufacturing process. These tools create 25 percent more feed compared with four-edge end mills and exhibit improved chip evacuation compared with six-edge end mills.

Ramping, Helix Milling and Drilling

When machining components, ramping, helix milling or drilling are often necessary for carving out pockets. However, conventional HPC milling cutters with four cutting edges often reach their limits because the chips must be discharged upwards efficiently and quickly, especially in the case of ramping, drilling and helical milling.

For this reason, the chip flutes on the end face must be large. Because of the design, the size of the chip flutes is more limited in the case of four-edge end mills than in the case of three-edge end mills. The Hoffmann Group has consequently developed a special milling cutter with only three cutting edges specifically for these applications.

To ensure efficient chip evacuation (important when ramping) a point geometry such as a drill has also been developed and moved back toward the shank. This design allows sufficient space to reliably evacuate the removed material away from the working zone.

Besides helical milling and drilling, the three-edge end mill can also be used for slots and side mills, covering all milling tasks without the need to change tools.

Roughing and Finishing

Modern HPC milling cutters leave behind such a smooth surface in some cases that the required finishing cut is no longer necessary. The new three-edge high-performance milling cutters from the Garant MasterSteel product line have been shown, for example, to eliminate the chatter marks that otherwise would occur when machining a fragile component made from 16MnCr5 steel.

For components produced using processes such as additive manufacturing or modern casting processes (near net shape), a finishing cut is all that is required for the final machining of functional faces, which can be performed using a seven-edge HPC finishing cutter. At a constant feed rate per tooth, a seven-edge end mill produces around 17 percent higher rate of advance than a classic six-edge mill.

With HPC milling cutters, the differences in quality regarding the geometry, the coatings, the carbide substrate and the edge preparation affect the tool life and the general performance. Design features such as the number of cutting edges and the shape of the end face play an important role in the machining task. Ultimately, advanced cutting tools can substantially shorten primary processing and non-productive times and significantly increase productivity by eliminating tool changes and superfluous work steps.

Related Content

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read More4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

Read MoreWhat Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreRead Next

When to Consider Customized Cutting Tools

What is the real cost of choosing standard or customized tooling if time is money and efficiency translates into profits? It’s a question many shops face regularly.

Read MoreMilling Hard-to-Machine Materials on a Micro Scale

The idea of a tool that effectively controls heat with a special grade of carbide, a new coating and internal channels that deliver cooling through ports in the shank where the milling flutes begin, is worth a look.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)