Keeping the Tradition

The attention that is given to advanced techniques such as turning materials of high hardness, ultra-precision turning and dry and high-speed turning may lead one to believe that traditional ISO turning techniques are at a standstill. The reality is that ongoing innovations keep traditional methods at the forefront.

It’s exciting to talk about new, advanced technologies that contribute to industry growth. But what about the old, reliable standbys that people so often take for granted? When certain products or methods are around for a while, they tend to be forgotten. However, that doesn’t mean they’re no longer useful. In fact, often overlooked modifications to these ideas keep them viable options.

Techniques such as multi-directional turning, for example, can offer more spectacular productivity improvements and cost reductions than the non-conventional alternatives, often with much lower starting costs. At the same time, the development of new carbide grades is blurring the boundary between ISO turning and other methods, such as precision turning of hard materials.

Increasing productivity and reducing costs have always been keys to successful business. In manufacturing, “productivity” can be viewed as the number of correctly finished products that are manufactured in a given time with the production facilities available. “Costs,” then, are an accumulation of expenditures that include the material costs, tooling costs, costs for the machine, wages and overhead for cooling, safety, infrastructure and so on.

If only tools are considered, quality improvement and higher cutting data offer opportunities for increasing productivity. Cost reduction can be achieved by adapting the tools and reducing the cutting data, resulting in longer tool life. Given that tooling costs account for only a small percentage of total costs, though, the increase in the tool life would need to be large to have a significant effect on the total cost. The situation is different for the cutting data: A nominal increase of 20 percent would lead to a substantial reduction in the production costs (as much as 10 to 15 percent) and also a clear increase in productivity. A considerable increase in the cutting speed, however, would decrease tool life, requiring more tools for an equal number of products produced. Higher-grade cutting tools and materials are thus required to reconcile these differences between budget and productivity.

The new generation of carbide grades, in that respect, plays a leading role. It is now possible both to increase the cutting data and to extend the tool life. Grades such as the TP1000 and TP2000, from Seco Tools Inc., have provided productivity increases of as much as 30 percent while reducing costs by as much as 20 percent.

Traditional Turning

Because of the relatively slow acceptance of new techniques, such as hard turning (sometimes called PCBN turning because the most optimum cutting material is usually PCBN), dry turning (turning with minimum lubrication) and high-speed turning, the turning technology in most engineering companies can still be termed traditional. Yet modifications to traditional methods have also proven to bring real productivity increases and cost reduction, even with low starting costs because no new machines and/or installations are necessary.

One method of increasing the efficiency of traditional turning methods is the use of a classification system for tooling to bring order to the enormous supply of carbide inserts. The Secolor classification model, developed by Seco, is one such system established to resolve the ambiguity of the existing ISO standard when determining suitable applications for carbide and chip-groove geometry. In this system, the choice of an insert is determined by the situation. For larger series, the technologically most suitable insert is chosen, determined by test series that measure cutting data and tool life during the application. A large stock of inserts is necessary to cover each situation. For smaller series, the whole range of use can be covered with a limited selection of inserts. Limited time does not allow for a test series, so stock and chip control become the focus.

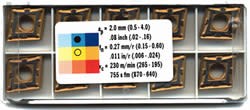

Applying a classification system in a turning operation allows quick, systematic selection of a suitable insert. A matrix matches the three basic types of material (steel, stainless steel and cast iron) against three machining conditions (finishing, medium turning work and rough turning work). For each of the nine basic applications thus defined, a basic insert is then proposed. Then, in a second phase, this choice is further optimized, where both the carbide grade and the chip-groove geometry are taken into account. With the Secolor system, the possible inserts are indicated on the insert packaging. The insert boxes show the range of application (within the nine fields of the matrix) and the basic cutting data (the recommended cutting speed, feed and cutting depth).

A second example of how significant productivity improvements can be achieved in traditional turning is through multi-directional turning (MDT). In MDT, one tool is used for all turning operations involved: facing and longitudinal turning, internal and external turning, parting off, profile turning, copying, grooving and thread turning. Inserts with such a universal function are subject to alternating stress, in all directions, requiring a perfect connection of the insert with the holder. This design promotes precise positioning (accuracy) when changing the insert and maximum stability of the insert in the holder. Stability is a crucial factor for safety, machining capacity, surface quality of the workpiece, avoiding vibration and repeat accuracy.

MDT is particularly applicable for small to medium series of complex workpieces with many different diameters, grooves and profiles. Typical examples are shafts of gearboxes, crankshafts, camshafts and fittings. For this type of complex workpiece, one MDT tool can replace a complete set of other tools, which results in machining cost savings. There is also a clear logistical benefit: The number of tools to be kept in stock falls drastically.

The Seco MDT system includes different basic types of toolholders and a choice of inserts: single- or double-ended; with and without chip-groove geometry; different nose radii; different geometries; different types of carbide; and different insert widths.

New Carbide Grades

MDT turning has established itself as a viable alternative in the ISO turning field, alongside long-known ISO tools. Yet these ISO tools continue to play an important role because they still represent the largest-cost item within the tooling budget. Further developments in cost control and achieving increased productivity continue to gain importance.

Chip-groove geometries should be addressed first, ensuring optimum chip formation and control. One element for increasing productivity without a proportionate cost increase is to turn with a high feed rate, and to ensure that the chip-groove geometry is adapted appropriately. Since the availability of turning inserts with wiper geometries, low feed rates are no longer necessary to produce good surface finish. It is now possible to use high feed rates for finish turning or to use low feed rates and achieve surface finish that is comparable to grinding.

The other element for high productivity is the selection of the most suitable carbide grade. Assuming chip formation is handled well, the carbide grade (and the cutting speed) can be used as the foundation for optimization.

Seco’s contribution in this area is the addition of the TP1000 and TP2000 carbide grades, aimed at the majority of applications in the ISO P-field. These grades are designed for higher wear resistance (higher cutting speed) and increased cutting edge toughness (higher feed rates). The substrate of these carbide grades is composed of a hard inner layer and a tough outer layer.

The optimized coating structure is composed of three functional parts and a number of intermediate layers. The inner base layer (titanium carbonitride) is responsible for a perfect adhesion and the basic cutting edge strength. The middle basic layer of aluminum oxide acts as an effective thermal barrier to permit higher cutting speeds, and the outer titanium carbonitride layer together with the titanium nitride top layer increase wear resistance.

Experience Counts

Although often obscured by more prominent metalworking operations, the turning industry continues to see significant developments. The productivity increases and cost savings that can be made are impressive.

On the one hand, there are a number of changes in technology, of which hard turning may prove to be the most important. On the other hand, there are a number of important changes in tool technology, including multi-directional turning. But the vast majority of turning operations, certainly in small series production, are still carried out with the traditional ISO tools. To make these tools and the corresponding cutting data profitable and to achieve an optimum turning process deserves attention. Recently developed chip-groove and point geometries and certainly the new generation of carbide grades form the impetus for a new wave of optimization.

While the opportunities for optimization continue to grow, the responsibility to take full advantage remains on the shoulders of the production people. They must have the necessary information and interest to convert the potential of the tools into real advantages, and they must be provided the opportunities to gain this knowledge.

Read Next

Tooling Up For Hard Turning

Hard turning isn’t hard to do. However, it does require an understanding of the process dynamics and a systematic approach to the tooling involved. This article looks at how proper preparation will deliver consistent, predictable hard-turning results.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More

.jpg;maxWidth=300;quality=90)