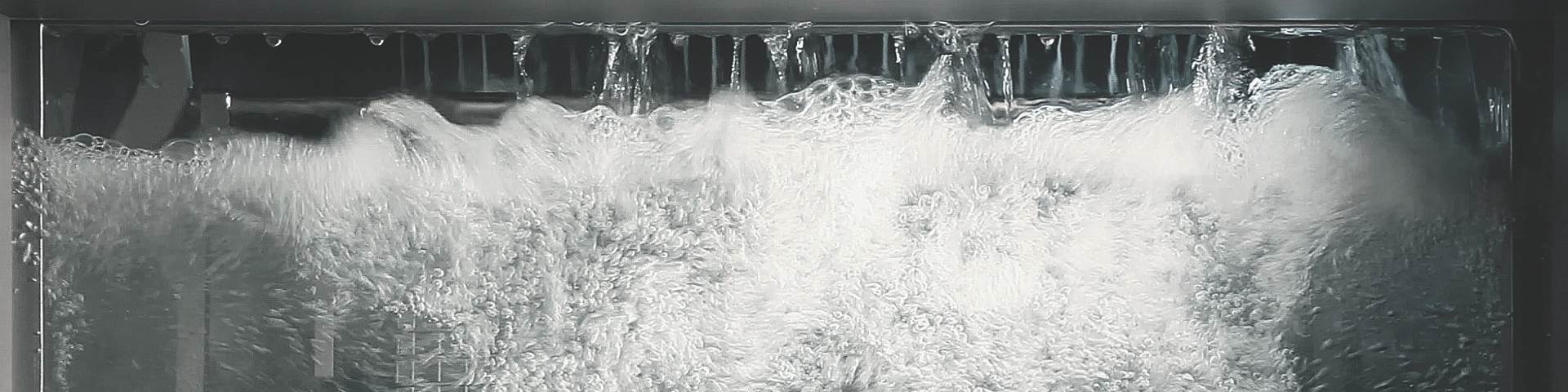

There are many ways to get your parts this clean. Research your options in the Parts Cleaning Knowledge Center. It contains everything you need to know about the science behind manufacturing cleaning.

Continual learning is part of our growth process and what makes us excel in our careers. To help with this, Production Machining has added a new Parts Cleaning Knowledge Center to IMTS spark. The knowledge center consists of updated articles written by manufacturing cleaning industry professionals who work for cleaning equipment OEMs and educational organizations. These articles include:

- Trends in industrial cleaning. Cleaning technology is being developed that is more effective for cleaning and drying complex metal parts that contain small recesses or holes.

- Cleaning processes. There are many cleaning equipment methods that will accomplish your goals, but knowing which one is ideal for an application is discovered with the help of cleaning equipment OEMs and/or professionals who specialize in solvent or cleaning agents.

- Corrosion protection. Learn about the different types of corrosion, as well as corrosion protection, post-cleaning corrosion prevention, and how to maximize cleaning and rust preventative programs.

- Cleaning regulations. Understand cleaning standards and regulatory trends and how to follow these regulations.

- Quality assurance and inspection for cleaning processes. Discover the most appropriate cleaning test for an application, cleaning compliance for automotive suppliers and more.

Informative videos are sprinkled throughout the knowledge center as well as white papers and other helpful links to educational materials.

While you are there, don’t forget to check out the Parts Cleaning Series’ on-demand webinars. Watch and learn at your convenience!

Related Content

-

Strengthening Manufacturing Workplaces Through Active Listening

A good strategy to weather the storms of manufacturing market upheavals and unpredictable factors is to commit to continuous, active employee listening.

-

2023 Emerging Leaders Strengthen Their Staffs, Solve Problems

Superb critical thinking, top-notch leadership skills and a passion for building a strong team are a few of the common traits held by this year’s five Production Machining Emerging Leader award winners.

-

New Thinking from the New Generation for the New Year

“We have to learn to think in a new way.” –Albert Einstein

.jpg;maxWidth=300;quality=90)