Leveraging ERP Software for Continued Growth

Shop management software has helped this toolmaker grow through streamlined operations and increased profit margins.

Running a small to medium size machine shop business can present many challenges. Alliance Broach & Tool (part of J&L Turning) in East China, Michigan, has faced a number of these challenges while building its operations and client base for more than 35 years. In spite

of the tough economic climate of recent years, however, Alliance has continued to grow—a lot, in fact.

“My father always said that if we were not growing the business we were on our way to being out of business,” says Mike Johnson, company president. Mr. Johnson’s father started the company in the family garage, along with Mr. Johnson’s mom, Helen Johnson, who is still involved in running the business. “As a young kid, I was always hanging around, learning to run the machines and helping to keep them clean,” Mr. Johnson says. “I eventually moved from one position to another, and as we started branching out to other products beyond our core business, I found myself managing more of the day-to-day operations.”

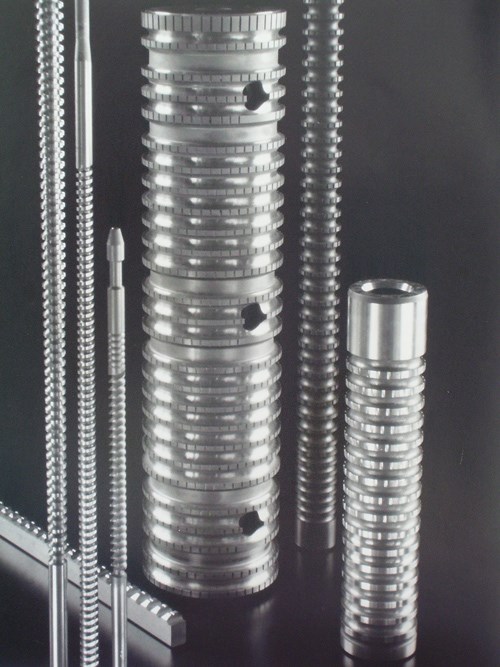

Alliance does highly customized broach manufacturing and reworking for a range of industries, from agriculture to aerospace, from automotive to medical, and from marine to heavy equipment. Each of the nine machinists on the shop floor is either a full-fledged toolmaker or an apprentice, and they operate various machines including an OD grinder, a lathe, surface grinders, spline grinders, thread grinders and broach sharpeners. The company has continuously expanded its operations and offerings to include highly specialized broaches of all types and specifications, including custom Spirex broaches and splines as large as 84 inches. “We are like custom cabinet makers,” Mr. Johnson says. “Everything we do is completely custom and done to the exact specifications of our customers.”

Keeping Order

Working with hundreds of customers both domestically and internationally, Alliance runs a tight, just-in-time operation. New customers and new markets are always top of mind. One of the tools that they have leveraged to manage both this growth and their costs is ERP (Enterprise Resource Planning) software from Realtrac. ERP software is a shop management tool that often can save companies—even very small firms—more money than any other tool on the shop floor.

The software allows Alliance to effectively manage its operations by providing up-to-date information at all times for quoting, costing and job scheduling. Many small shops believe that using a program such as Realtrac Performance ERP should be delayed until they are able to grow their business further. But these shops often miss out on significant cost savings by waiting. “We had a pretty quick return,” Mrs. Johnson says, validating this point relative to Alliance’s experience. “The improvement in our job planning, cost analysis and floor operations meant that within a matter of months, the software had paid for itself.”

Mr. Johnson says the time and money saved by effectively using ERP software has made a huge difference in his company’s profitability. “The saved history in our system helps us develop quotes more quickly and more accurately, and if I want to know the status of any item on the shop floor, that information is just a few clicks away,” he says. He estimates that through the years, the company would have had to add several additional administrative people to do the same sort of tracking and management that its Realtrac ERP software provides. “I know about a project, especially if there is a problem, before anyone from the shop floor comes to my office to talk to me about it. Even better, once we make an adjustment or resolve a problem, it is documented and we don’t have to revisit it later.” In an increasingly global marketplace, this type of efficiency is important for a shop of any size to stay competitive and keep the business growing.

A Day on the Job

Including Mr. Johnson, Alliance has four people involved in front office operations, directly involved in the use of Realtrac. All of the employees, though, are well versed in the shop side of the software—it acts essentially as a time clock that logs all data for a job.

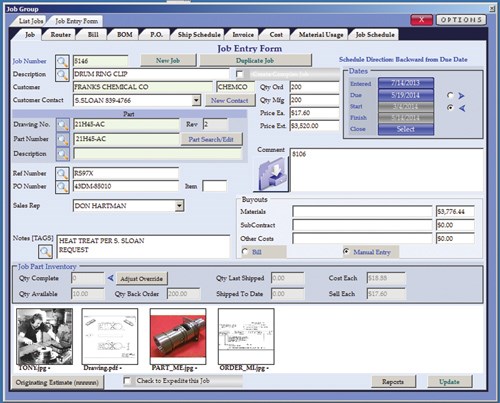

When a request for quote comes in to Mr. Johnson, he creates it in the ERP system. But if the RFQ is for a product similar to something the company has produced before, that previous job can be copied and adjusted as needed to tailor it to the new item to save time. He specifies the work process—the machines and the times on each operation. If something might require special attention, he is able to include notes to call it out.

Once the quote is accepted, the customer submits a purchase order and the office manager turns it into a job, giving it a number with a button push. All information is automatically transferred to the job, and the tracking sheet, print and notes are printed and placed in the job envelope.

“The quote is generally the extent of my involvement in the job,” Mr. Johnson says. “The jobs are fully planned before hitting the shop floor, and I spell out everything in the job packet for the operator. When the operator gets the job packet, he clocks it in. From there, the system tracks incoming inspection, the sharpening process, and any additional machining. It’s all tracked.”

A customer calling with questions simply provides the purchase order number and Mr. Johnson can retrieve all of the necessary information from his computer. He can see that it is in process, what operation it is in, and even provide an estimated completion/delivery date.

Mr. Johnson has been in the business for more than 30 years, so he knows the advantages of this efficient approach to job management. “Years ago, we did this manually. A lot of shops still do,” he says. “We would have to input an operator’s times to check to see how we made out on the job. In the past, there was no way to even find a job unless you went out into the shop looking for it. Now, a customer calls with questions about existing jobs, and I don’t even leave my desk.”

Better with Teamwork

Occasionally, Mr. Johnson and others at Alliance think of new ways that they feel their ERP system could potentially improve their processes. If they are not aware of how to get it done, they don’t hesitate to call Realtrac for help. Realtrac has often been able to come up with a solution that works with the existing features of the software. This open communication has been beneficial to both companies.

In March, Realtrac released its latest version of the software (Realtrac 10). But for several months before the release, Alliance acted as a Beta customer. “We offered to do that as a current satisfied customer,” Mr. Johnson says. “We devoted some extra time on the transition, running both the new and older version at the same time. This required entering all data twice, but it provided a legitimate, side-by-side comparison of the software and also helped to ensure that our operations continued as normal, keeping everything in a format with which we were familiar and comfortable.

“We have not officially upgraded to the new system yet, but we’re confident that when we do, it’ll be a simple process. The new version is easier to use and incorporates a lot of new features that will simplify data input.”

Roots of Change

Alliance isn’t the only company seeing positive results from Realtrac. In 1989, Bob Sakuta was running a ten-person manufacturing supplier for the automotive industry. Although business was solid, he knew he needed to bite the bullet and make further investments into the growth of the business.

He, too, implemented Realtrac software and has since seen an 8,000 percent increase in profits, allowing him to add four more companies to his portfolio. He was so impressed with the impact of the ERP system that Realtrac is one of the companies he chose to buy.

The software was originally built in the early 1980s by a machine shop owner, but it eventually went to the open market. Mr. Sakuta wanted it back in the hands of a machine shop owner who was more in touch with changes and current trends in the industry. He reached out to the owner and was able to purchase the company in 2012.

“I believe Realtrac is the main reason for our success,” Mr. Sakuta says. “I bought it out of passion, knowing it was good, but wanting to make it great.” Since that time, he has assembled a new group of programmers and a steering committee comprised of current users within his manufacturing group as well as existing customers to develop what would become Realtrac 10. This latest version is designed to assist a shop in its entire operation, from management to inventories to implementation through added functionality.

Features incorporated in Version 10 are designed to increase the functionality and flexibility of the system while maintaining speed and ease of use:

- Built-in business intelligence with a detailed messaging system

- Completely integrated job folders that include every piece of data needed for a job (purchase orders, job data, routers, bill of materials, and so on)

- Improved document handling, including the ability to attach any document to the job folder

- Streamlined searches for any document or process within or across job folders

- Touchscreen interfaces to leverage tablet PCs

- Remote Start mobile app for iOS 7

Saving More than Money

Any owner of a busy machine shop knows that running a smooth operation with tight scheduling and minimum inventory levels is absolutely vital to staying profitable and, in many cases, staying in business. Shops often rely on only two or three individuals to manage the operations. Good ERP software helps businesses to operate with less administrative head count, perhaps freeing up funds to hire additional productive floor personnel. A strong ERP system tracks the entire job and coordinates the work flow for all current projects, providing instant visibility to the entire team on the floor and in the front offices.

ERP systems also help firms prepare for audits and certifications. With a few simple key strokes, the documentation needed for almost any type of audit or certification process can be completed. This regularly saves dozens of hours that can be focused on producing parts rather than searching for and compiling documentation.

“We’ve been using Realtrac software since 1994, and I know it has saved us a ton of money,” Mr. Johnson says. Building efficiencies into every process means that even small and medium sized firms such as Alliance Broach & Tool get a very fast return on the investment they make into an easy to use ERP package. No matter how small a firm is or how complicated or streamlined the operations are, ERP software should be considered. It is no longer something that is just for big business or very sophisticated operations.

Related Content

Avoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read MoreDeacom Essentials ERP Software Helps Digitally Transform SMBs

Deacom Essentials gives manufacturers a cost-effective, tailored ERP software solution to gain better insights into operations in order to make informed decisions and scale their overall business.

Read MoreSustainability Analysis Tool Aids Data-Driven Decision-Making

Can increasing productivity and reducing carbon emissions go hand-in-hand? For its high-volume machining customers, Sandvik Coromant offers a tool for data collection and comparison to aid sustainability-minded process decisions.

Read MorePrecision Machining Technology Review: November 2024

Production Machining’s November 2024 technology showcase includes some of the latest technology from Vericut, Hurco, the L.S. Starrett Co., LNS North America, Fryer Machine Systems and MachineMetrics.

Read MoreRead Next

Software Helps Small Machine Shop Become Lean Manufacturer

This CNC machine shop searched for software that would help make the transition to lean manufacturing easier.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More