Articles

Let Us Make Buying Easier

Providing quick access to supplier contact information, the Buyer’s Guide is designed to set up readers for a smoother and more effective buying experience at any time throughout the year.

Read MoreBenchmark Your Business with Top Shops

Shops that fill out the Top Shops survey before Feb. 10 receive a customized report that they can use to help improve their businesses.

Read MoreProduction Machining Activity Contraction Slows at Year End

The Precision Machining Index moved higher in the last month of 2019, registering 47.6. December’s relatively higher reading compared with the prior month’s indicates that business activity contracted at a slower rate in the latest month.

Read MoreMeet Cate Smith, PMPA’s New Executive Director

Cate Smith was recently named the executive director of PMPA. She brings to the table a range of experience relating to professional association management.

Read MoreWebinars: Listen to Top-Rated Precision Machining Discussions on Hot Topics

Listen to webinars on 3D metal printing, shopfloor management, next gen development and simulation processes for additive manufacturing.

Read More3D Printing vs. CNC Milling for Prototyping

Many factors, such as price, part size and material come into play when deciding whether 3D printing or CNC milling is the best method for making a prototype.

Read MorePMPA Tech Talks—Listen, Discover and Connect

PMPA Tech Talks cover important topics such as operations, benchmarking, metallurgy and digital security.

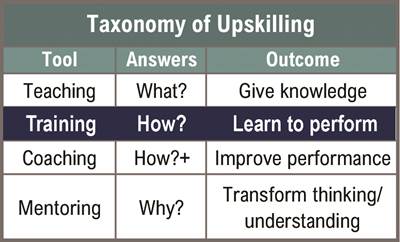

Read MoreWorkforce Development—Training Shows How

To expand on his “Workforce Development—What We Can Do Better” article, Miles Free explains the Who, What, Where, When, Why, How and How Many of one of the four upskilling tools—training.

Read MoreR.F. Mau Uses Conservative Approach to Grow

Brian Adams, fourth-generation president of R.F. Mau, and vice president/general manager, Tony Gemignani, discuss the past, present and future of the company.

Read MoreHow to Reduce Steps Required in Nonferrous Surface Finishing

The finishing of parts made from various copper and aluminum alloys traditionally require many distinct and separate process steps. Hubbard-Hall’s Mike Valenti explains how both come with their own unique needs .

Read MoreGetting Ready for Lights-Out Manufacturing

Lights-out manufacturing has the potential to save money while increasing capacity, but shops need the right equipment and to address potential challenges before implementing it.

Read MoreDeburring Difficult-to-Machine Materials

A wheel brush with nylon filaments that will not break off or deform can remove burrs from hard materials, such as 4140 steel.

Read More

.jpg;maxWidth=300;quality=90)