Living Large In A Materials World

He lives and breathes aluminum, stainless, carbon steel and brass because that’s what has brought him this far. However, his methods for winning in business show he’s not your typical material guy.

Craig Yarde has built Yarde Metals (Southington, Connecticut) on the principles of sharing the wealth for the satisfaction of his associates—the 600-plus employees throughout the organization who are devoted to the business philosophy and work hard each day for the good of the company and themselves. It has paid off big time in continual growth to the tune of an average of almost $300 million in sales in each of the last 3 years. Employee morale at Yarde is high—very high. The formula for this winning combination comes from ownership that cares about its employees and views happiness and job satisfaction for each individual as the key to success for the company. It’s a formula that can work anywhere.

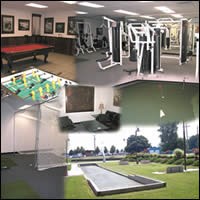

When employees walk through the front doors each day, they’re greeted with an atmosphere resembling an entertainment facility more so than a typical place of employment. Surrounding the lobby is a museum of memorabilia, with old mill photos, books and other antiques that represent the metals industry. Just beyond the main entrance is an indoor café where food service is offered for breakfast, lunch and dinner. That’s only the beginning. There’s a reason why people throughout the Hartford area are vying for positions in this company. Throughout the day, employees can take advantage of such amenities as full exercise facilities (a 1,000-square-foot fitness center with a complete line-up of treadmills, weight machines and free weights and a separate aerobics/Pilates room with a personal trainer on staff), a massage room, a full-size putting green, an indoor driving range, a Bocce court, a dog run, a horseshoe pit, a basketball court and a gazebo equipped with a grill. The company even has a designated nap area—a room with low-level lighting and two couches—to allow any employee a chance to get away from the stress for a while and regroup.

The employees are firm believers in the strategy of implementing a comfortable work environment and sharing the profits. They are happy to work hard and provide an all-out effort to ensure customer satisfaction, and they are rewarded for going the extra mile. They might not see the reward on the next paycheck, but they see it when they look forward to going to work, and they see it when their efforts turn to profit and the semi-annual profit-sharing checks come in that award as much as 49 percent of an employee’s income. A tour through the facility with Craig provides a first-hand look at what the emotions are really like there. Each employee receives a warm hello from Craig and returns it with the same. The sincerity is apparent, as everyone is on board with these proven strategies of success.

Early Days

In the early 1970s, Craig began working for a stainless distributor who was making a lot of money picking up materials from the docks and reselling. It was a time when foreign materials were starting to come into the country, and the Japanese were bringing in low-priced garden-variety grade. Craig saw an opportunity to make some money in the industry, and he began his own business out of his basement in 1976 with $1,000 from the sale of his motorcycle.

When he first started, he knew if he could get at least one order a week, he could survive, and anything over and above would help grow the business. He would deliver orders with the family station wagon, dealing mainly with companies who could pay quickly, as he delivered the bill by hand with the materials. It was his aggressiveness that made the difference. His goal was to out-service all competitors and do whatever he had to do to make the customer happy.

After a year in business, Craig partnered with his brother, Bruce, and moved the company into a small, rented factory. By 1986, they were able to move into an 85,000-square-foot facility to accommodate the growing product line, services and sales, but it took about 15 years to accumulate enough retained earnings to the point where the company could start leveraging what they had and reinvesting to grow the business.

Today, the company holds about 45 million pounds of inventory, including a good variety of hard-to-get items. With its own machining department, the company can supply non-standard sizes and shapes, create a tube from a bar or make a hex out of a round. Each day, 700,000 pounds of material go through, with 100 trucks running as many as 1,700 items a night. However, it took time and the right blend of hard work and positive attitudes to achieve the current levels of performance.

Making The Grade

According to Craig, the screw machine industry was the beginning of the company’s success. “Although we now sell to any industry, brokering stainless and aluminum rods to that small niche is what gave us the foothold.” Even today, almost 25 percent of Yarde’s business is supplying screw machine companies, and many of the philosophies that Yarde applies would be well suited for this industry.

“In the screw machine industry, there’s a lot of labor, and how a company taps into that labor is the key,” Craig says. “How can a company get more productivity, and what is that productivity worth?” Craig feels that to get the most out of the labor, a business owner needs to be up front with the financial position of the company and be willing to reinvest in the employees. “If you’re the owner, you deserve to get a return on your investment. You started the business; it’s yours, and you put everything at stake. But ‘profit’ shouldn’t be a dirty word. If the company is making money, the profits should be celebrated and, to whatever extent possible, shared.”

It’s with these principles that Craig started what he terms the Yarde Zone www.yardezone.com, a business philosophy of open-book management that recognizes the value of each individual in the organization. The playing field is leveled throughout the organization, financial records are available to all employees, profits are shared and employees are “wowed” by various lifestyle amenities and a fun work environment.

Craig states that one of the strengths of the Yarde Zone is the labor element. “A lot of companies have different forms of compensation. Some involve labor to a certain extent, but most focus on the front-office people. If they don’t take care of the labor, though, they don’t get anything out the door. Even with the best sales department in the world, if the labor does not have the right attitude, they can find a lot of ways to slow the process down. The chemistry is what makes it work.”

In this can-do environment, everyone is an owner and feels a strong need to service the customer. The teamwork has led to unbelievable growth for the organization. In the last 3 years, Yarde has gone from $150 million in sales to $385 million, and Craig says that the business philosophy is as much to thank for that growth as the strong economy. “It’s hard to measure people’s happiness. You can measure pounds out the door or dollar volume, but how do you quantify trust, effort and job satisfaction? To me, the best indication is the bottom line, and our growth of sales and profits since implementing consensus management seems to provide the answer.”

In Transition

Craig and the other associates at Yarde apparently are not the only ones impressed with the company and its management style. In mid-July, the company announced its sale to Reliance Steel & Aluminum Company (Los Angeles, California). A chain of events initiated by the recent retirement of Craig’s brother, Bruce, led to a tough decision for Craig. “The company had taken out a lot of debt over the last 3 years to support our recent growth,” Craig says. “We had leveraged pretty much everything we had. With a large credit line coupled with my brother’s portion of the company, a downturn in the market would have put everyone in the company at risk.” Although it was his preference, Craig felt it would be selfish to keep the company private, so he moved forward with the sale to Reliance.

If an offer such as that from Reliance was not available, though, Craig says he would not have sold the business. Consistent with his business philosophy, his concern was with the best interest of the entire staff. Reliance retired the company’s entire debt and also paid the Yarde brothers the $100 million value of the company—in real dollars, not company stock. This deal allowed the Yardes to split an additional $9 million among the associates. Meanwhile, Reliance plans to keep the same business philosophy in place at Yarde while expanding it to a billion-dollar company within 5 years.

Even during negotiations for the sale of the organization, Craig kept his associates informed. He did not feel comfortable dropping a bombshell at the last minute. His management style has been greatly appreciated and is proving to be Yarde Metals’ strongest asset. The associates recently showed their appreciation by placing a full-page ad in a recent edition of the local newspaper to thank the Yarde brothers for sharing their success. The ad concluded with the words, “Please know that the values you have taught the Yarde Metals ‘family’ will continue to live within each of us—at work, in our homes and in our hearts.” It’s clear that taking care of who Craig calls his “most important customers,” his associates, will continue to drive the success of the business well into the future.

Read Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More