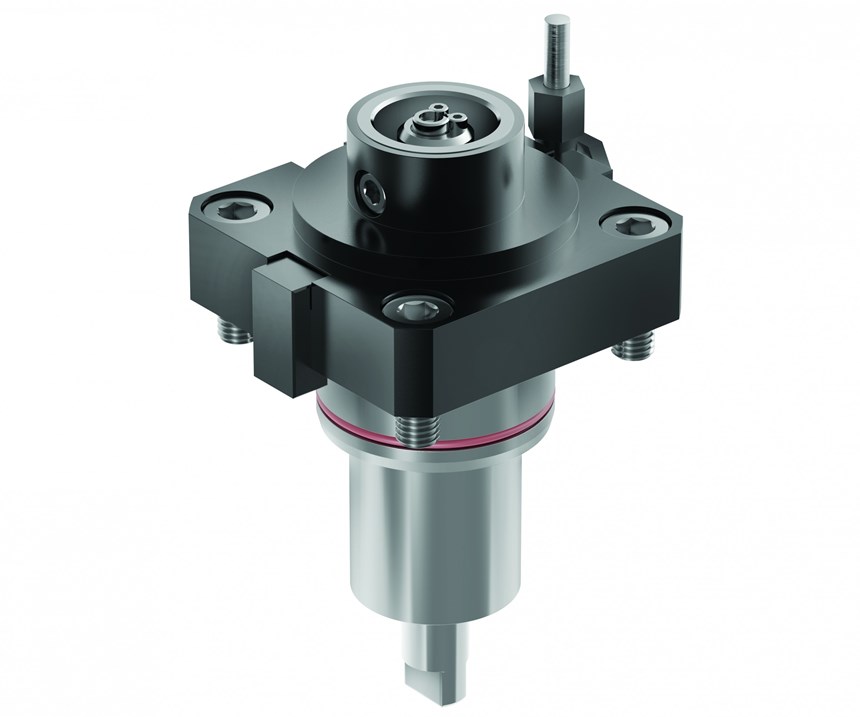

Turret-Adapted Clamping Unit Provides High Clamping Forces

In place of the standard turret tooling available on CNC lathes, the KM product line of turret-adapted clamping units from Kennametal and EWS Tool is designed to improve shopfloor efficiency.

As machine tools become increasingly complex and the need to produce parts in less time grows, CNC lathe owners and managers must look to the latest technologies to improve shopfloor efficiency. Sometimes, however, that improvement can be done by looking to the past. Kennametal, has done that with a new KM product line of turret-adapted clamping units—a spin on the almost three-decades-old KM quick-change tooling system.

Kennametal has partnered with EWS Tool Technologies to manufacture and support this series of KM adapters. Together, the two companies plan to redefine how shops will tool up the turrets on their DMG MORI, Okuma, Mazak, Haas, Doosan, Nakamura, Hwacheon and Hyundai lathes, with more to come.

Embracing Change

Quick-change tooling might not be an obvious choice for everyone. It might be too expensive or not worth the hassle that comes with implementing new technology. That might be why some machine shops choose to take the path of least resistance and use the standard turret tooling that came with their CNC lathes. “I spoke to a lot of customers at the last IMTS and EMO shows, and my best estimate is that 80 percent of them do not use a quick-change tooling system,” says Michael Schuffenhauer, manager, tooling systems at Kennametal. “I was very surprised, and to me, it indicates a tremendous opportunity for these shops to become more competitive.”

Turret adapted clamping units support this opportunity by replacing the standard block-style turret tooling with quick-change capable adapters made for a shop’s specific brand of CNC lathes. This applies to both Mazak VDI- and BMT-style turrets, whether they are rotating or static, and for toolholders with axial, radial and even angular orientation. Consequently, quick-change can be easier to implement, reducing both tooling costs and concerns about toolholder rigidity.

Building Bridges

“Available machining time is one of the key contributors to any manufacturing company’s productivity,” Mr. Schuffenhauer notes. “Reducing setup is a big part of improving this metric—something that quick-change tooling systems excel at. But there’s also the downtime that comes during tool changes, when the operator spends 10 minutes looking for the screw that fell into the chip pan, for example, or the time lost by having to touch off a drill in the middle of a job. KM eliminates this non-productive time, and turret adapted-clamping units are the bridge between the system’s quick-change capabilities and the machine tool.”

Offset and inline clamping unit models are available, as are ones for right- or left-hand placement. The list of KM adapters includes hydraulic chucks, ER collet holders, shell mill adapters and ID and OD turning cutting units. The clamping unit interfaces a range in size from 32 to 63 mm (KM32 to KM63). The turret-adapted clamping units are suitable for applications on a lathe, mill-turn machine or multitasking center producing parts from tiny medical screws to bearing hubs large enough for a tractor trailer.

Doing the Math

Mr. Schuffenhauer adds, “KM uses a pair of hardened steel balls that sit within a tapered tool shank. As clamping force is applied, the tail end of the taper expands while the toolholder is pulled back against the locating face. Together with a small amount of interference at the gage line, this three-point contact provides extremely precise radial and axial positioning and repeatability, as well as high clamping forces.”

Jay Verellen, Kennametal director of global product management, tooling systems, points to the ROI calculator on kennametal.com as a way to quantify improvements in machine utilization and alleviate any concerns about cost. He notes that a potential positive return on investment (ROI) in as little as three to six months is not unusual, and that the company’s customer application support (CAS) team is ready to help customers ensure they are getting the value they seek

“It’s not a terribly complex calculation,” he says. “Enter a few inputs such as hourly rate and number of setups per shift and it’ll make sense pretty quickly.”

But shops should also consider the less tangible effects of KM. “Setups and in-process tool changes are simpler, so having a less skilled operator isn’t a scary proposition,” Mr. Verellen says. "They add flexibility as well, not only in the variety of tools and adapters that are available, but in the ability to help keep the customer happy. If you can set up a machine in five minutes, it becomes much easier to meet their changing demands without losing your shirt.”

For more information from Kennametal Inc., call 724-539-5000 or visit kennametal.com.

Related Content

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MorePiezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.

Read MoreTungaloy Grooving Toolholders Provide Stable Turning

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Read MoreMonaghan Compensation Chucks Convert Standard ER Holders

Diatool ER Hydraulic Compensation Chucks enable users to convert standard ER holders to a repeatable, steerable hydraulic chuck for more precise machining.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More