Micro Drill Cuts to New Depths

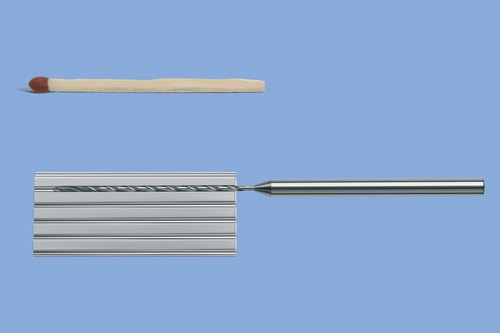

At the EMO show, Mikron Tool demonstrated a new addition to the company’s Crazy Drill line of cutting tools--micro drills capable of drilling deep holes from 0.1 to 1.2 mm in diameter in increments of 0.01 mm at depths as much as 30x diameter.

At the EMO show, Mikron Tool demonstrated a new addition to the company’s Crazy Drill line of cutting tools. Called the Flex Drill, it’s a micro drill capable of drilling deep holes from 0.1 to 1.2 mm in diameter in increments of 0.01 mm at depths as much as 30× diameter.

The drill combines the advantages of HSS (flexibility) with the tool life properties of solid carbide. The advantage being the drill is less likely to break in the cut because of positioning errors.

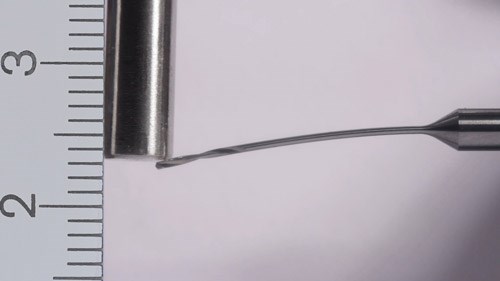

The concept is based on a new type of carbide alloy and a unique geometry. The design uses a flexible shank extension that allows it to flex significantly more than a solid carbide drill. This forgiveness simplifies deep hole drilling using small-diameter tools.

As many shops look to operate unmanned or lightly attended shifts, reliable small-hole drilling is a major criteria for successful operations in hole diameters less than 1 mm. HSS drills offer the flexibility to take lateral pressure from misalignment, but offer relatively short service life. Carbide on the other hand, has better service life, but is prone to breakage because of its lack of elasticity.

Mikon has combined the advantage of HSS with the tool life of carbide, it its new line of drills. In a demonstration in the company’s booth at EMO, a Flex Drill was bent off center by up to 0.6 mm with no breakage to show the elasticity of the design.

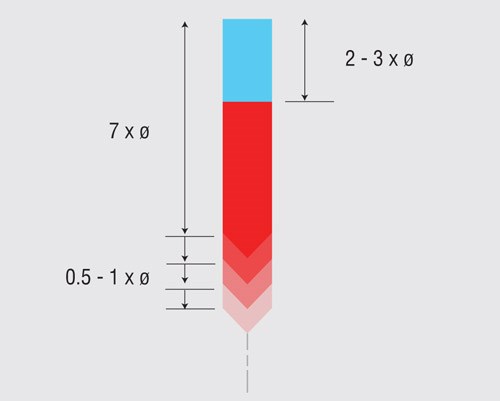

The company sees this new drill, capable of 20× to 30× diameter, as an alternative to gun drilling, EDM and or laser machining for creating micro holes. In operation, a pilot drill (3× diameter) is used to open the hole from a solid.

The pilot acts as a guide for the deep hole drill. This two-step process is designed to enable the shop to perform precise drilling with good reliability because of excellent chip flow from the drill geometry. The point angle for both the pilot and the Flex Drill is 140 degrees.

With the pilot hole in pace, the Flex Drill is fed in increments of 7× diameter using a peck routine until the final depth, up to 30× diameter is reached. This operation is easily performed on standard CNC machine tools.

The drill’s new flute geometry allows for strong chip compression by allowing space for the chips to flow up the flute. The 140-degree tool tip directs the flow of chips in an axial direction away from the cutting action, which functions to reduce the feed force and torque necessary for cutting while facilitating good chip breakage at the cutting tip.

When compared with other micro-drilling processes the company claims the Flex Drill to be

10× faster than gun drilling or EDM. In a test cut of ten holes that were 0.5-mm in diameter and 15-mm deep, the Flex Drill took 3 minutes to perform the operation versus 24.4 minutes for a gun drill and

30 minutes for EDM.

This new deep hole drill and its cutting process using a pilot hole and pecking routine is designed to be effective in numerous materials on standard machine tools. Aluminum, brass, copper and steel are examples of materials that have been successfully drilled using these new drills.

Deep hole drilling in small diameters has historically been somewhat of a “black art” with the impression being that special machines and close monitoring are required to be successful. With the new Flex Drill concept, much of that trepidation can be eliminated.

Now, deep holes less that 0.5 mm can be machined on standard machine tools using tried and true drilling techniques programmed into the machine’s CNC. The combination of HSS tool shank flexibility and the cutting tool life of carbide may well be something to consider if micro drilling is among the shop’s operations performed.

Among the successful applications of this micro drilling product has been the watch industry, medical parts manufacturing and machining of fuel injectors for the transportation industry. Even with the use of a pilot, the increased feeds and speed afforded by the carbide cutting characteristics of the Flex Drill make it competitive with most other hole making processes.

Related Content

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreMicromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More