Practical Deburring Provides Cost Savings

Because Jagemann Stamping was using manual deburring, which is not a controlled process, can cause injury and is costly, the company decided to search for a new deburring process.

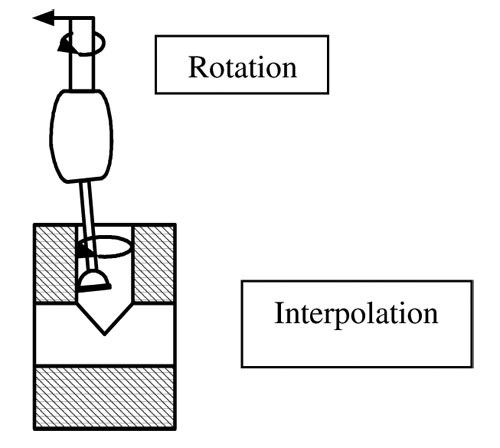

This video illustrates the live Orbidrive deburring process.

Striving to satisfy customers is a way of life for any shop. So when Jagemann Stamping (Manitowoc, Wisc.) wanted to automate an ID helical deburring operation on a two-axis lathe, they knew the solution was not easy.

"We were making tubular parts with cross-holes, and deburred them by hand with a manual deburring tool," says Rob Bartz, a mechanical designer. Manual deburring is not a controlled process, can cause injury and is costly.

As a manufacturer of deep-drawn metal stampings since 1946, Jagemann’s high-speed transfer presses are capable of producing stamping from aluminum, steel, stainless steel, brass and pre-coated steels. Raw material thicknesses used by the company vary from 0.010" to 0.15". Jagemann also offers heat treating and surface treatments along with assembly, pressure testing, polishing and custom packaging. This second-tier supplier has a customer base that is more than 50 percent automotive.

Because the company is dedicated to producing high quality products, finding the appropriate solution to the deburring problem in a timely manner was critical to the project’s success. While looking into several options, management made it clear that, most importantly, the company wanted an automated deburring operation that offered consistency, quality and robustness. A three-axis machine was considered, but the Orbidrive interpolating unit from J.W. Done ultimately fulfilled the company’s wishes. "J.W. Done offered a new solution for our application in order to automate the deburring," Mr. Bartz explains. "The Orbidrive provided the capability equal to a three-axis spindle at a fraction of the cost and complexity."

The Orbidrive is designed to use J.W. Done’s Orbi-tool technology, that allows cross-hole deburring to be done at the spindle. To accomplish this, the Orbitool is required to move in a thread-milling-like routine, also known as helical interpolation. However, high-production equipment such as screw machines and transfer machines often lack this three-axis capability. The Orbidrive was developed to remedy this problem. This attachment mounts on a one-axis spindle and performs all the necessary functions to accomplish deburring with Orbitool without having to retrofit a three-axis machine.

The Orbitool is designed to mount into a toolholder on a lathe or machining center and operate basically like a conventional cutting tool. It removes burrs from the intersection of holes and can be tailored to leave a minimally broken edge or blended radius. An Orbitool consists of a hemispherical shaped cutter and a disk fixed on the end of a shaft. The cutter and disk resemble an upside down bowl on a saucer. The disk is larger than the cutter, which is a key to the tool’s operation. The other key feature is the Orbitool’s flexible assembly, which allows it to reach any edge created by the intersecting holes. In operation, the tool is partially inserted in one of the intersecting bores, close to the intersection. The tool is then moved laterally until the disk contacts the wall of the bore. This contact causes the Orbitool to deflect slightly.

At this point in the process the cutter is rotated and fed down into the bore using a helical interpolation routine. As the disk approaches the edge of the bore’s intersection, it falls off the bore wall and allows the cutter, which is under load from the deflected flexible coupling, to machine the burr. Like a cam follower, the disk traces the contour of the cross-hole intersection, so only the burred areas come in contact with the cutter. When the operation is complete, the cutter is moved to the center of the bore, clear of the wall, and retracted.

Now that this new equipment is installed, the quality, cost and effectiveness of the deburring operation has improved and stabilized. Mr. Bartz says the real benefits are in the robustness of the process; the tool life of the Orbitool allows for the cutting of tens of thousands of holes. He adds that the cost of the

Orbidrive installation has paid for itself.

The operators are able to adjust the deburring program and change out the tool without involvement from engineering. No news is good news from the internal customer as well," he adds.

"Cross-hole deburring is a new process for us, and the Orbitool has worked for two parts so far. In the future, this tool will be useful in deburring IDs of other drilled holes," Mr. Bartz explains.

Because of the Orbitool/Orbidrive, Jagemann can ensure superior quality of cross-holed deburred parts.

Read Next

Ban The Burr—A Look At ECD

Deburring is a consideration, and often a problem, for all manufacturing engineers. The burrs resulting from a metalworking operation may be tolerable; however, burrs are always present.

Read MoreBolt On Deburring

Burrs are a nemesis for most metalworking shops. And cross-hole burrs are among the worst cases that shops encounter. For most applications, deburring must be done off-line as a secondary operation.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)