Reengineering of a CAM Engine

Software suppliers are doing their part in meeting the programming demands of multitasking operations for complex parts.

As part requirements continue to increase in complexity and the trend for smaller lot sizes forces shops to rethink their approach to adding machine tools, multitasking machines are playing a more significant, growing role on the shop floor. Software suppliers are doing their part in meeting the programming demands for this shift as well.

At IMTS 2014, Gibbs and Associates (a Cimatron company), developer of GibbsCAM software for programming CNC machine tools, is introducing GibbsCAM UKM (Universal Kinematic Machine), the engine behind the upcoming release of GibbsCAM 2015. This CAM engine is completely reengineered, taking a new approach to how it will relate to machine definitions and machine tools. It blurs the line between the definition of mills and lathes.

Bill Gibbs, company CEO and president, says, “CAM systems were designed based on the way mills and lathes were originally created to move. Mill-turns and multitasking machines started merging the two. GibbsCAM UKM was created from the ground up with no limitations. It can handle any number of axes in any direction, with multiple tools cutting simultaneously. With this software, users can program and accurately simulate virtually any machine today.”

A Closer Look

The benefits of the engine extend throughout the entire product line, not just those areas relating to complex machines. Improvements to rendering and machine simulation help to give customers the confidence that what they see on the computer screen is what will happen at the machine. Machine simulation and post processors are built on the same kinematic model, optimizing the programmer’s time and ensuring complete accuracy.

The new UKM architecture is backward compatible, so current post processors and machine simulation models for GibbsCAM will continue to provide a return on investment. In addition, customers will be able to program and simulate the most complex machines on the market, including machines from Bumotec, Citizen, DMG MORI, Doosan, Matsuura, Mazak, Nakamura-Tome, Okuma, Star, Tornos, Willemin-Macodel, and others.

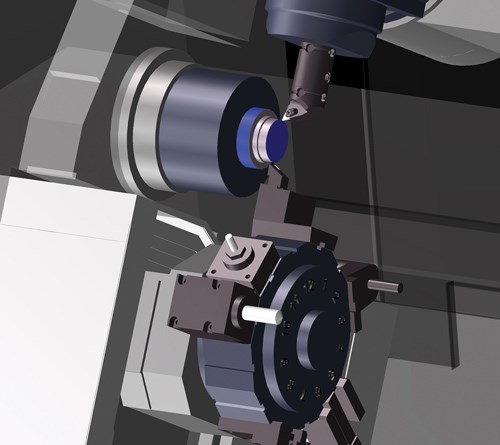

Significant changes have been made to the tooling functionality of GibbsCAM 2015. In addition to new tool types being added (barrel, dovetail, convex tip, E-style ISO insert, and tools defined by solids), the software now has dynamic 3D viewing of tools and toolholders in the tool dialog, allowing users to accurately visualize the tools they are selecting for the job.

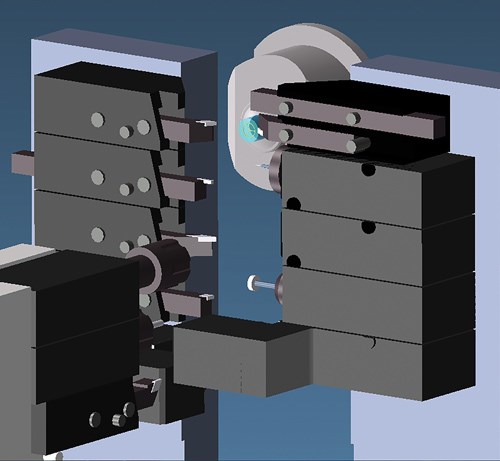

An entire new category of tooling called Intermediate Tooling has been added. This feature allows for items that are neither tools nor fixed parts of the machine, such as fixtures (chucks, tailstocks, steady rests) and toolblocks (adapter blocks, holders for toolholders, and so on). Programmers can create libraries of toolblocks for easier setup of complex machines and can share those libraries across different parts, saving time and reducing errors.

The Big Picture

The software is designed for significant improvements for a range of programming and machining processes, from geometry creation to toolpath strategies, including additional high speed machining (HSM) strategies. New functionality has been added to aid in the importing and machining of hole features. Holes are now treated as fully associative features of solid bodies, including those imported from SolidWorks, Solid Edge, Autodesk Inventor, or CATIA V5. Compound holes (holes with multiple segments that might each be tapered or threaded) are now supported, as well.

New geometry tools include improved spline editing and contour tracing capabilities. Improvements to machining include new adaptive roughing capabilities, pre-drilling and background processing for VoluMill, and many new capabilities for the Tombstone Management System, a comprehensive system for programming parts on a tombstone.

The current GibbsCAM product line supports two- through five-axis milling, turning, mill-turning, multitask simultaneous machining and wire EDM. The software also provides fully integrated manufacturing modeling capabilities that include 2D, 2.5D, 3D wireframe, surface, and solid modeling. It is compatible with Windows 7 and Windows 8 and is certified for Windows Vista.

Related Content

Mastercam Software Improves Programming Flexibility

IMTS 2024: Mastercam introduces Mastercam 2025, with features including Mastercam Deburr for automated edge finishing, finish passes, mill-turn support for Y-axis turning and automatic license update notifications.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAD/CAM system. Here’s how the company succeeded despite the newness of it all.

Read MoreIntegrated CAD/CAM Software for Maximum Efficiency

PMTS 2023: This software solution is said to enable users to take advanced mill-turn and Swiss-type machining to new levels of speed, efficiency and simplified programming.

Read MoreRead Next

Seeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More