Reliable Cleaning for Large Lot Sizes

A solvent cleaning process that is well matched to the job’s requirements can provide a quick, efficient and ecological solution.

When workpieces are mass produced in a chip-forming process, the parts are usually cleaned within batches, frequently with the help of solvents. This manufacturing step often results in a production bottleneck. If chips and residual processing media are not removed from the parts, the entire production process can appear inadequate to the customer. If cleaning is time-consuming and cost-intensive, production capacity, efficiency and yield are reduced.

Reconciling quality, throughput and cost requires the right solvent and a system concept whose process technology is well matched to actual process requirements as well as an optimized cleaning basket that is well suited for handling the parts. Selecting the best equipment and process for an application requires a close look at the component geometry, material, type and degree of contamination, processing status and required degree of cleanliness.

Using the Right Solvent

The solvent that is used has a decisive effect on cleaning results. Solvents used commonly for machining processes include non-halogenated hydrocarbons (HC) such as isoparaffin and modified alcohols, as well as chlorinated hydrocarbons (CHC) such as perchlorethylene (per), trichloroethylene (TRI) and methylene chloride (MC).

Hydrocarbons and modified alcohols are distinguished by their chemical compositions, which provide them with both non-polar and polar characteristics. The primary application for non-polar HC cleaning agents is degreasing because they have shown particularly good performance in dissolving animal, vegetable and mineral oils and grease. But modified alcohols usually have better degreasing capabilities than pure hydrocarbons. Cleaning agents based on modified alcohols that demonstrate lipophilic and hydrophilic characteristics are suitable for difficult applications such as cleaning lapped parts, sintered metals and top quality, high precision small parts.

Because hydrocarbons and modified alcohols are highly volatile and combustible substances that, as a rule, are used at temperatures above the flashpoint in industrial applications, their use requires systems technology including appropriate explosion and fire protection.

Non-combustible chlorinated hydrocarbons are very good grease solvents, have minimal surface tension and are chemically very stable. As a rule, they allow for effective removal of non-polar oils and slightly polar grease from components with complex shapes—without corrosion, oxidation, discoloration, burning, dulling or other surface impairments. CHCs are preferred where critical oils (chlorinated and highly sulfurous oils) are carried-over into the cleaning medium along with the parts to be cleaned. Because of their evaporation rates, chlorinated hydrocarbons offer advantages in drying when compared with HCs and modified alcohols. Generally speaking, they dry faster and more completely, making them preferable for parts with critical drying characteristics. This quick drying is often essential in parts with complex geometries and capillaries.

Matching the System to the Application

Hydrocarbons and modified alcohols, as well as CHCs, are now used in fully closed, single-chamber cleaning systems with integrated distillation units that recondition the solvent. These systems allow for recirculation of the utilized solvents. The cleaning process can be laid out in several stages that can vary based on the application. Commonly, the process will include cleaning, vapor degreasing, rinsing and drying. It’s also possible to integrate several solvent tanks, for instance, for coarse and fine cleaning, as well as for parts preservation.

A trend towards cleaning systems that are operated under full vacuum has become apparent. The process engineering advantages and low-temperature distillation capabilities of these systems clearly has driven this development. As a result, the solvent is subjected to less stressing, and its service life is increased. Furthermore, vacuum operation with combustible solvents (HCs and modified alcohols) eliminates the need for additional explosion protection.

If oil or grease is carried over into the cleaning process by the parts to be cleaned, external bypass distillation should be used. This second distillation circuit allows continuous removal of oil and grease. A mixture of grease and solvent is continuously drawn into the bypass distillation unit from the bottom of the system distillation unit and is concentrated under vacuum, and the separated grease is discharged automatically.

Various filter systems, such as bag filters and tube filters, are available for removing particulate contamination from the solvent. A combination of various filters may make good sense, depending on the degree of cleanliness required. Particularly in the case of multi-shift operations, laying out the filters as a double system can be advantageous. This format allows switching from one system to the other while production is running, and the currently unused filter system can then be cleaned. Where large volumes of parts need to be cleaned, automatic feed equipment represents a further option for optimizing workflow.

Short Cleaning Cycles

Immersion processes can be used for workpieces with complex geometries resulting from drill holes, undercuts, blind holes and so on. Contaminants that adhere to parts are removed in the immersion bath primarily by the medium’s chemical cleaning effect. This effect can be boosted by swinging or rotating the cleaning basket. Other physical process, such as ultrasound and flushing under pressure, can be applied in varying degrees to effectively remove particulates and further shorten cleaning times.

The cleaning effect of ultrasound, which can achieve high degrees of cleanliness in very short periods of time, is based on cavitation. The bath fluid is acoustically irradiated by an ultrasonic generator and a matching vibration system. Oscillations produced in this way cause the formation of minute hollow spaces within the fluid that collapse immediately. Strong currents and turbulence develop and “blast” the contamination away from the workpieces to be cleaned. Generally speaking, the lower the frequency, the more energy is released.

In the case of pressurized flow cleaning, pumps draw fluid out of the cleaning bath and subsequently inject it back into the bath at high pressure levels through nozzles located underneath the fill level. This flow results in strong currents that cause turbulence at the edges of the components to be cleaned, thus removing the contamination. When the fluid flows past blind holes and recesses, a suction effect is generated that draws out contamination.

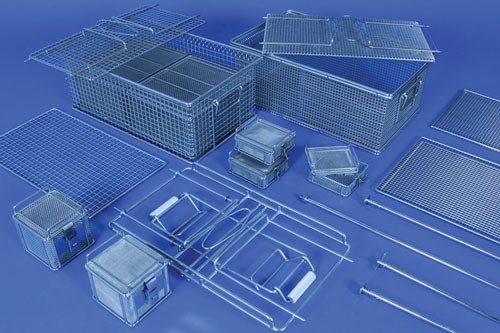

Don’t Forget the Cleaning Container

In addition to the selected chemicals and process technology, the cleaning container can play a vital role in quickly and effectively processing bulk or individually positioned parts through the cleaning system. Good accessibility to parts in the basket is a prerequisite for quick and reliable removal of contamination. Only in this way are the workpieces uniformly exposed to the cleaning agent so that the mechanical washing process can develop its full effectiveness and wash out film-like contamination and particulates as efficiently as possible. This efficient cleaning is made possible through the consistent use of round wire. Unlike closed containers or baskets made of perforated sheet metal, cleaning baskets made of round wire are also distinguished by significantly better draining characteristics, resulting in considerably less carry-over of contamination and cleaning agent.

Related Content

Overcoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

Read MoreCorrosion Prevention: How to Avoid the Enemy of Metal Parts

This chemical reaction that is a constant, indiscriminate and costly enemy of metal parts is preventable, but intentional measures must be taken and become an essential process within a company’s walls.

Read MorePMTS 2023 Product Preview: Parts Cleaning

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

Read MoreKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreRead Next

Simple, Effective Parts Cleaning

After trying an array of parts cleaning methods over the years, this shop has implemented an environmentally friendly, relatively simple system to clean every part it produces.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More