Shop Combines Automated Grinding and Swiss Turning

Many shops are increasing the scope of their machining capabilities. This Ohio shop has added cylindrical grinding to its 24-hour Swiss-type operations.

When Copen Machine’s customers started requiring higher volumes and quicker turnarounds, the company’s grinding suppliers couldn’t keep up. As a result, the president of the company, Travis Copen, decided to bring some of the high-volume grinding operations in-house. He thoroughly researched advanced CNC grinders, focusing on those best suited for automation.

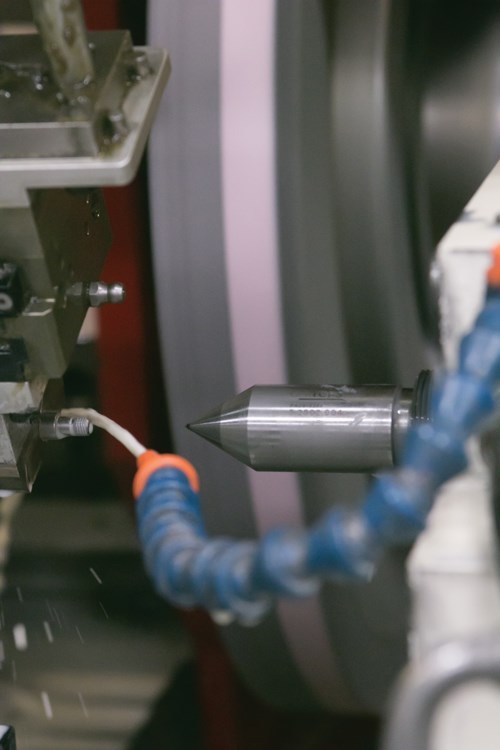

Copen Machine’s first grinding machine was a Studer S22 CNC production cylindrical grinder from United Grinding North America. The machine offers a maximum grinding length of 800 mm and a center height of 175 mm.

“We kicked the tires and liked the fact that the machine was solidly constructed and fully enclosed,” Mr. Copen says. “The enclosure is optimal for automation. Parts can move in and out of the machine without having to open it. That capability increases process consistency, which is the key to successful unattended operations.

Founded in 1978, Copen Machine has grown from a garage job shop with a single manual knee mill into a full-service machining and fabrication provider specializing in high-volume precision parts. The company achieves high-volume production through 24-hour-a-day operation of CNC Swiss-type turning machines in conjunction with automated CNC cylindrical grinding operations. About a third of parts produced on Copen Machine’s Swiss-type machines require precision grinding.

Now located in Kent, Ohio, the company offers a range of machining services. Its major customers include those in the commercial food processing, firearms and physical security industries. The company processes a variety of materials, from steel and aluminum to plastic, titanium and super alloys. However, stainless steel parts comprise the majority of the company’s production.

The company has three facilities. The main plant houses CNC Swiss machining and CNC cylindrical grinding. A second one houses conventional CNC turning and milling, and the third handles fabrication and manual machining.

Into High Volume

High-volume CNC Swiss machining has always been Copen Machine’s strength. Its main facility houses 18 Citizen CNC Swiss lathes continuously producing annual part runs in the millions, 6 days a week in a lights-out environment.

In 1994, the company added CNC capability with a custom-modified boring mill. With the new equipment came new customers and additional equipment. Customer demand for smaller precision parts in larger volumes prompted the purchase of the company’s first CNC Swiss-type lathe in 2003.

As key customers continued to experience rapid business growth, demand for Swiss machined parts accelerated, creating a need for increased capacity. Copen went from machining 100,000 parts a year for a particular customer to more than a million a year.

The Need for Automated Grinding

With Copen’s growth came the need for more automation as well. After buying its first grinder, Copen Machine worked with robotic integrator Matrix Design for the S22 cell that consists of the grinder, a FANUC 100i robot and a gantry loader. The robot takes parts from manually racked trays and loads them onto the gantry that delivers the parts into the grinder.

“We needed the ability to load 1,000 parts at a time into the machine so it would be able to run for a significant number of hours,” Mr. Copen says. “The grinding and robotic loading process can be below 30 seconds per part. Our lot sizes for automated grinding range anywhere from 1,000 to 50,000 parts. For us, it’s not practical to set up an automated 100-piece run of basic OD ground parts.”

He added that the plan was to automate the grinding process immediately with lights-out operations being the goal from the start. The company replaced the standard coolant filtration arrangement and instead installed a deep bed filter to remove large amounts of material produced by continuous operations. There is also a larger mist collector that features a high-efficiency particulate arrestance (HEPA) filter to absorb mist that could negatively affect humidity and air quality in the temperature controlled facility. Key personnel are also present in the plant to check on cell operation, troubleshoot problems and pull parts for SPC inspections.

Striking a Balance

While the automated S22 added significant production capacity, the production output of the Swiss machines outpaced the grinding cell. Consequently, Copen Machine added two more Studer Universal Grinders—an S31 and S33—and is in the process of automating both machines.

Part precision requirements at Copen Machine dictate grinding strategies. Typical machining size tolerance is ±0.0002 inch. Grinding tolerances may be half that, surface finish requirements as fine as 4 Ra and roundness/cylindricity tolerances are 0.000050 inch or better. Parts are machined from barstock as small as 0.125 inch in diameter. Some production shafts exceed 12 inches long.

Tight tolerances and the possible flexing of longer parts often require OD grinding between centers. Parts usually feature multiple diameters and interrupted cuts. The shop step dresses its grinding wheels to produce multiple diameters. Interrupted cuts, on the other hand, pose a bit more of a challenge.

“We run parts that require that we hold both tight overall tolerance as well as even tighter roundness tolerance. On top of that, they may have an interrupted grind surface,” Mr. Copen says. “To handle this, everything has to be right. It’s impossible to grind over a milled flat and hold 0.000050-inch part roundness unless you have a strong, solid machine. That’s why we went with Studer grinders. Their mineral-casting Granitan bases are rigid and provide optimum thermal stability. At 18,000 lbs, the machines do not move.”

Some Lessons Learned

The S22 grinder at Copen Machine features a 24-inch-diameter wheel. The bigger wheel has a large surface area and offers longer life between dresses. Mr. Copen says a company that is interested in high-volume CNC grinding should consider a machine with a larger wheel. He added that he always avoids using machines that have anything less than a 20-inch wheel.

The company employs aluminum oxide wheels and dresses them with rotary diamonds on the S22 grinder and with stationary diamonds on the other two Studer machines. There is virtually no dresser wear.

Careful dressing techniques are necessary because the 630 stainless steel that is the company’s mainstay workpiece material will quickly load up any wheel, according to Mr. Copen. He added that the steepest learning curves involve selecting the proper wheel, finding a feed rate conducive to grinding gummy stainless steels, then establishing dress frequencies that will maximize process reliability.

Copen Machine develops reliable parameters through comprehensive testing—first trying different grinding wheels, then tweaking the process through continuous improvement. “You have to be very patient when grinding,” Mr. Copen says. “You take small, controlled steps and document everything you do. You have to dim the lights before they can go completely out for lights-out grinding.”

Mr. Copen added that maintaining a customer’s desired part surface finish is to a large degree determined by the grinding feed rate and dressing frequency, which also affects wheel life. “If you grind too fast, you are going to load the wheel and need to dress it more. On the other hand, if you grind more slowly and less aggressively to prevent wheel loading, you are going to burn the part surface,” he says.

Once he has determined appropriate grinding and dressing parameters, Mr. Copen relies on Studer integrated software that provides grinding parameters, modules for wheel contact detection and automatic wheel balancing along with other functions that ensure trouble-free grinding. Additionally, the software aids in automated operations through monitoring of wheel wear and the condition of machine components. Because many of the parts that the company grinds are similar, Copen Machine stores, then slightly modifies grinding programs whenever possible to keep part change-overs typically within 2 hours.

All three of the shop’s grinding machines have in-process gaging that is especially valuable on long production runs. Mr. Copen says that in the company’s high-volume environment the carbide contacts of the in-process gaging system exhibited rapid wear. Installing diamond contacts remedied the problem.

Continuous preventive maintenance, according to Mr. Copen, is imperative when it comes to high-volume, lights-out automated grinding operations. “You can’t skimp on routine maintenance because machines are only as reliable as you keep them,” he says. “Diligent preventive maintenance comes with a cost, but it is something you must do.”

Maintenance activities include daily inspection for dirt and sludge buildup and overall cleanliness of automation grippers and machine coolant. Proper coolant pressure and fill levels are also inspected. Weekly checks should cover automation belts/conveyors and other components, while monthly checks focus on machine lubricants and hydraulics.

Mr. Copen says preventive maintenance is a team effort, with operators performing some of it on a daily basis. “The key is cross training at every level. The automation dictates the volume of production we are able to get, and the maintenance helps us to achieve it.”

Smooth running, trouble-fee automation provides high-volume throughput along with process and part consistency. “Automation has added about 35 percent to our existing capacity,” Mr. Copen says. “We don’t automate to eliminate jobs. We do it to increase capacity and enhance job opportunities. Automation takes the pressure off our machinists so they can focus on quality.”

In addition to producing high volumes of top quality parts quickly, Copen Machine has established procedures that enable it to meet demanding customer delivery requirements, including shipments within 24 hours and servicing of Kanban systems. Mr. Copen says, “It comes down to the ability to produce high-quality components consistently. You can make a million good parts in our niche, but one bad part can cost you a customer.”

Related Content

The Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MoreEmag Grinding Solutions Provide Precise Gear-Profile Grinding

The G 160 and G 250 gear-profile grinding machines provide short chip-to-chip times, intelligent axis concepts as well as thermal and mechanical stability.

Read MoreLissmac Grinding Machine Provides Versatile Surface Finishing Performance

The EBSC grinding machine is capable of processing both tri-dimensional and flat parts, allowing for broader applications across various industries.

Read MoreStuder S100 Grinding Machine For High-Precision, Flexible, Reliable Grinding

The machine is well suited for a wide range of internal, surface and external grinding applications, making it well suited for the entry-level market.

Read MoreRead Next

A Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)