“Component quality” is a buzzword often mentioned in gear manufacturing. However, at Humbel Gear Technology in Switzerland, it is particularly important. The gears and transmission components developed and produced here are used in applications including motor sports and prototypes to enhance electric drives—extremely challenging fields with small batch sizes. A “standard” measure of component quality is not enough in these cases.

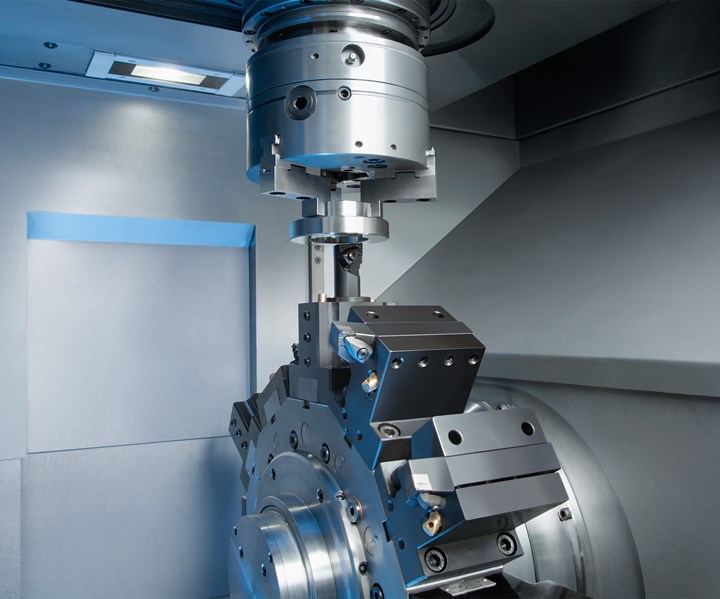

The VL 4 vertical turning center from Emag features a turret with 12 posts that’s suited for driven tools and is designed for short indexing times.

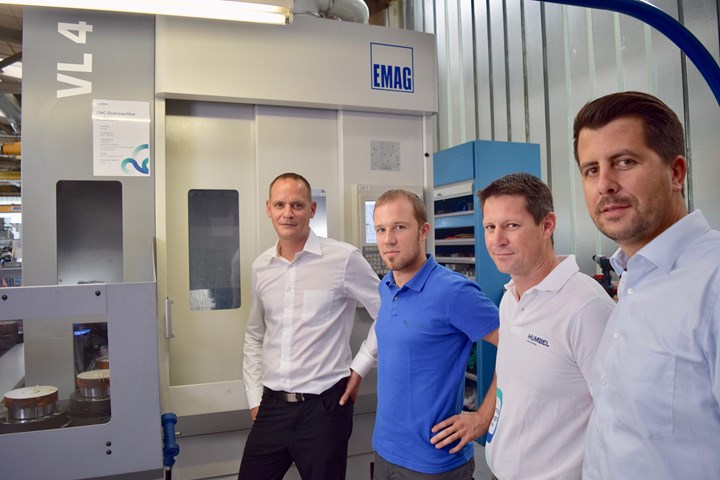

Humbel recently expanded its machine inventory to include a VL 4 vertical turning center from Emag. According to the company, the machine’s automated pickup spindle provides a boost in productivity while the machine’s other features ensure the required component quality in the main machining operation. After only a few months in operation, the Swiss specialists said they were “surprised by the machine’s stability and performance.” It has helped the company fulfill its mission to produce precision gear and transmission components and could help the company add new business in the future.

‘Humbel’ Beginnings

Humbel Gear Technology was founded in 1928 as a “gear factory.” The business, which is still family owned, has a main location in Kradolf, Switzerland, along with two subsidiaries in Romania and the Czech Republic. When asked to describe the company’s particular expertise and selling points in a nutshell, Alex Humbel, general manager, doesn’t think twice. “‘Precision’ is the deciding word for us,” he says. “At our main location in Switzerland, we produce very sophisticated gears and transmission components, which really require the highest quality.” Its customers operate in demanding industries that require precise parts, including Formula 1 and Formula E, aerospace, various fields of mechanical engineering, and electric car prototyping. Perfect surfaces and high component stability are essential—not massive unit volumes. Batch sizes of 200 parts are the higher end for the Swiss location.

The VL 4 performs various machining processes on the blanks, including turning and drilling, on a range of components.

The company distinguishes itself with a strategy of vertical integration. It performs all processes for gear production, including turning, gear cutting, grinding, cubic machining, electrical discharge machining and hardening. “We have developed into a highly specialized, full-service provider and, in addition to customer and application-specific manufacturing, we also offer gear development,” Mr. Humbel says.

Investing in New Equipment

In April 2018, the Humbel Group added an Emag VL 4 with O-belt automation and a FANUC CNC control unit. Emag’s sales partner, Suvema AG, headquartered in Biberist, Switzerland, provided targeted advice regarding equipment and configuration. Suvema has experience with the equipment, having handled the sales of Emag manufacturing systems in the alpine republic since 2016. “We highly value comprehensive service and also know the requirements of the local production industry,” explains Daniele Corso of Suvema AG. “Based on this, we are able to more effectively introduce Emag technology to the market.”

Humbel Gear Technology produces precise gear and transmission components using vertical turning machines such as the VL 4 from Emag (shown here with Alex Humbel, managing director at Humbel Gear Technology; Thomas Vollenweider, head of the turning epartment at Humbel; Pascal Wanner, technology and engineering at Humbel; and Daniele Corso of Suvema AG).

The fact that the company invested in Emag equipment is not surprising. “We have already been using Emag technology for quite some time,” Mr. Humbel says. But the choice of machine, a VL 4 compact vertical turning center with a pick-up spindle for automation, might be.

The VL 4 is part of Emag’s modular standard series of machines that are built on a common machine base and enable customers to use a range of technologies including turning, gear hobbing, chamfering, grinding and induction hardening. It includes a base made from Mineralit polymer concrete for vibration damping and process quality. The machine base supports a compound slide rest equipped with an X axis and a Z axis, which enables the working spindle to move.

The working spindle is the heart of the VL series’ pick-up automation system. The machines include a parts storage unit, from which the pick-up spindle loads and unloads itself independently. This lowers non-productive time, so there are as little as a few seconds between machining processes. An optional measuring probe can be installed directly alongside the loading position, enabling time-optimized measuring of the parts.

The VL series of machines is available in five sizes to cover a range of possible parts. The smallest, the VL 2, is designed for chucked parts with diameters as large as 100 millimeters. It is followed by the VL 4, VL 6, and VL 8 machines, each of which can handle an additional 100 millimeters in diameter. This enables the series to cover workpieces ranging to 400 mm in diameter.

Each VL machine is equipped with a tool turret with as many as 12 driven tools for machining chucked parts. This turret is designed to be dynamic, with fast indexing to cut non-productive time to a minimum, which in turn reduces cycle times. The machines can also be equipped with a Y axis in the turret for machining complex shapes, expanding the possible applications of the machines.

A Centralized Automation Solution

Blank pieces are fed into the system on a conveyor belt from which the pick-up spindle loads and unloads itself automatically.

The VL series of pick-up turning centers were developed for the production of precise chucked parts and are most often used to process large batch sizes. However, Humbel uses it to soft machine flange components in lots of 50 to 200 parts. So why did the company decide to invest in this machine? “Above all, it is the integrated pick-up automation system that convinced us,” Mr. Humbel says. “This approach enables us to increase our productivity even with smaller unit volumes. At the end of the day, once the machine has been configured, the overall process requires little manpower and still runs reliably.”

The system’s ease of use was another draw for the company. “The Emag automation solution is designed in as simple a manner as possible,” Mr. Humbel adds. “Many alternative automation concepts from other suppliers seem more complicated to us than the Emag solution and therefore also fault-prone.”

Turning Provides the Basis for Quality

Many of Humbel’s customers operate in demanding industries that require precise parts and small batch sizes, such as Formula 1 and Formula E, aerospace, various fields of mechanical engineering, and electric car prototyping.

Humbel also considers required component quality when investing in new equipment. If the company’s turning centers can establish an ideal basis in the main machining operation, it benefits the processes that follow. “If we obtain a high quality at this stage, it is easier to design the subsequent grinding processes and thus to guarantee perfect results,” says Pascal Wanner, who is responsible for implementing the Emag machines at the Humbel Group. “We are able to guarantee this initial quality in the process with the VL 4.”

The machines are also helping Humbel deal with some of the challenges it faces regarding the materials it uses. For example, the motor sport components are manufactured from high-alloy case-hardened steels, which are relatively difficult to machine. In this and similar contexts, the specialists benefit from the machine’s other features. These include the Mineralit polymer concrete base, which reduces vibrations during the milling process and ensures longer tool lives; the main spindle, which is fastened to the front of the machine with a compound slide rest to enable dynamic movement in the X and Z axes; and the 12-post tool turret, which is suited for driven tools and is designed to reduce indexing times. “The machine’s stability and performance surprised us,” Mr. Wanner says. “Our infeeds and feed rates are actually higher than we expected.”

The Machine Fits the Strategy

The gear and transmission specialists at Humbel are so satisfied with the overall performance of the VL 4 that the company has invested in additional Emag machines for its subsidiaries, including a VL 3-DUO turning center and VL 8 for the Romanian location as well as a VL 8 and a VMC 450 (yet to be delivered) for the Czech location.

The machines have proved so successful for the company that they could potentially help open doors to new business. “Especially in Switzerland, our strategy remains to produce particularly sophisticated components,” Mr. Humbel says. “However, we do not only consider ourselves to be a manufacturer of single parts, but we also have an eye on complete transmission assemblies for the future—for example, in the areas of motor sports and e-mobility. The flexibility and cost-effectiveness of the VL 4 open up all kinds of opportunities for us.”

Humbel Gear Technology | humbel-gears.com

Related Content

5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

Read MoreReinventing the Wheel with Robot-Automated CNC Multitasking

One race team discovers how to efficiently manufacture a new wheel nut design for the next-generation NASCAR stock car with the help of a CNC mill/turn and a built-in robot.

Read MoreNomura DS Showcases Turning and Milling Machines Engineered with Excellence

Gosiger offers the comprehensive line of Nomura DS machine tools at competitive prices.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read MoreRead Next

Vertical Turning Upside Down

Using the main spindle for double-duty machining and workpiece load/unload makes sense. It’s a simple idea that has grown in sophistication from turning to multitasking. This article looks at the state of the art using inverted vertical turning for precision volume production.

Read MoreHard Turning with Inverted Vertical Turning Centers

When it comes to the machining of hardened surfaces, hard turning is a particularly efficient solution that, compared with grinding, offers a radical reduction of machining times and investment costs.

Read MoreCombining Hard Turning and Grinding

A combination machine that is capable of both turning and grinding work in a single setup might provide the capabilities a shop needs to address an ever changing work flow.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)