Shorten Cycle Times for Tube Machining

Suhner, in cooperation with Wagner (a German manufacturer for OD thread rolling heads), has developed a special process that allows threading operations in short cycle times.

Prep operations for tubings and pipes generally require multiple manufacturing steps such as cutting, chamfering, face-off, turning and tapping, including thread milling or thread forming.

High part quantities, usually combined with the need for different manufacturing steps, demand efficient and time-saving production methods to help reduce time and cost. Special-purpose machines, such as rotary and linear transfer machines, typically offer the best solutions to help obtain shorter overall part cycle times.

Through its experience with operations on transfer machines, Suhner Industrial Products has worked to optimize a manufacturing process with standard or custom solutions for each machining application. One specific application is for large and long OD threads. These operations can be challenging for manufacturers when trying to obtain shorter cycle times because an OD threading operation by itself will dictate the overall machine cycle time.

Thread Rolling

Suhner, in cooperation with Wagner (a German manufacturer for OD thread rolling heads), has developed a special process that allows threading operations in short cycle times. A pneumatic cylinder-activated system is used to open and close the thread rolling head, which is equipped with multiple thread cutting or forming inserts.

The workpiece is fed from barstock material. After a cut-to-length operation, it is machined by three Suhner BEX15 machining units with special Weldon toolholders. Operations include OD, ID and face turning. All units are equipped with a 1.5-kW motor and high precision angular contact spindle bearings.

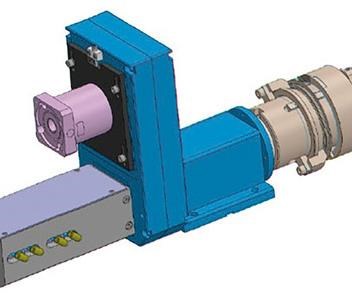

The station for an OD threading operation, which is accomplished with a BEX35-ISO40 machining unit equipped with a Wagner thread rolling head type Z27-2, is the most interesting station on this machine. In this operation, the thread rolling head is rotating and the workpiece is stationary. The feed motion for this station is done with a CNC slide unit. In order to synchronize the thread pitch, both the BEX35 spindle and the CNC slide are servomotor-driven.

As soon as the threading operation is finished, the Wagner thread rolling head, with integrated inserts, opens quickly to allow a fast return to the home position. Opening and closing of the head is accomplished by an internal BEX35 drawbar, controlled by a three-position pneumatic cylinder. This pneumatic cylinder is designed to make an additional stroke of 10 mm, allowing for head and insert adjustments or replacements, depending on thread size.

Depending on length, a typical OD thread rolling cycle time ranges between six and 10 seconds. Thanks to the application of CNC servo-driven spindle and slide components, customers can achieve very short change-over time, as well.

Process Components

Thread rolls. The rolling thread is the actual forming tool. The rolling profile is worked in as a parallel peripheral chamfer. Thus, having the same flank lead, various thread diameters for either left- or right-hand threads can be rolled with the same machine setup. Needle bearings or carbide nuts bear the threads. To tackle the numerous tasks involved, various types and qualities of rolls are available.

Roll holders. The roll holders support the thread rolls and fit at the inside of the cam ring. They differ according to the diameter range and the worked-in lead angles of the thread to roll.

Few roll holder sets cover the whole work range of a thread rolling head. Roll holders for regular and fine threads, trapezoid and special threads, and right-hand and left-hand threads can easily be replaced.

Thread rolling head. This component supports the roll holders, opens up after thread rolling and can be positioned precisely according to the rolling diameter. Constructing the proper head is relatively easy. It facilitates controlling the energies of cold forming. The size accuracy and permanent operation of the rolled threads, even with workpieces up to 1,700 N/mm2 of tensile strength, is therefore guaranteed.

Shank. As the connecting element to the machine, the shank isn’t fitted with operational elements of the rolling head mechanism. Thus, it can be replaced easily by thread connections. Various shank types for almost every tool fitting for different machines are available. Additionally, the shank serves as a die for a stop, if needed.

Flexible System

The axially working Wagner thread rolling head rolls the threads in a large working area, which is made possible by the fast and easy exchange capabilities of the roll holders. They differ in the working area size and the holder angle, ensuring that the threads with different profile shapes can be machined with left- or right-hand threads using the same head. Other shaping work such as beading, knurling, rolling-in and smoothing can also be achieved. The heads are suitable for rotating or stationary use.

The axial head is closed by radially turning the locking lever or locking roll or by an automatic locking device. The head’s opening mechanism will be activated when the feeding stops, and the rolls will release the workpiece.

Maximum productivity can be realized by the use of high precision thread rolls, which are held in place by the roll holders. These can be optimized to match the required pitch, diameter and shape of the rolling thread. The thread roll serves well as a shaping tool when the profile that must be rolled is machined as a parallel circumferential groove.

Read Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)