Manufacturing Tech. Classroom of the Future

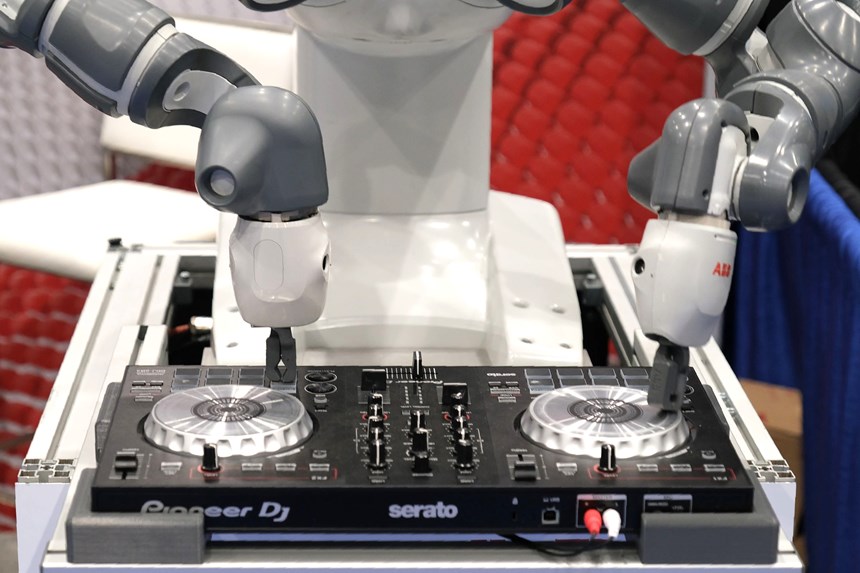

Interactive exhibits in the Smartforce Student Summit demonstrate smart, digital manufacturing technologies (Industry 4.0): additive manufacturing, augmented and virtual reality (AR/VR), automation and robotics, digital twin, generative design, and more.

In the ongoing effort to attract youth to manufacturing careers, IMTS 2022 continues to do its part by creating the industry’s “manufacturing technology classroom of the future” at the Smartforce Student Summit. The 12th edition of the event delivers content to provide thousands of students and educators with fun and engaging learning experiences centered around career and technical education (CTE). Taking place in the North Building, Hall C, the event runs Monday through Friday, 9 a.m. to 3 p.m. and Saturday, 9 a.m. to 1 p.m.

Interactive exhibits from leading manufacturers demonstrate smart, digital manufacturing technologies (Industry 4.0), additive manufacturing, augmented and virtual reality (AR/VR), automation and robotics, digital twin, generative design, and more.

Showcasing the technology and equipment that best suits the curriculum that schools need to be teaching is how Greg Jones, vice president – Smartforce Development at AMT – The Association For Manufacturing Technology, defines the manufacturing technology classroom of the future. “It’s one thing to teach CNC, but you really must have CNC equipment in those program labs,” he says. “And the same is true when teaching robotics, automation and smart digital manufacturing while providing the best kind of real industry robots and mechatronics in those classrooms.”

He adds that the Student Summit not only is about informing students of the technology and STEM (science, technology, engineering and math) career paths available, but it is also about selling products to the schools to properly outfit their program labs.

A 20-ft.-wide by 100-ft.-long display in the center of the event hall offers students a hands-on manufacturing experience. Autodesk and Haas Automation have partnered together on a manufacturing experience enabling students to design a part in Fusion 360 software, program that part for machining on a CNC mill or lathe, and measure the parts at the end of production. The CNC machines set up in the display area have robots or cobots integrated on them to demonstrate loading blanks and unloading finished parts onto and out of the machines.

A display in the center of the Smartforce Student Summit event hall offers students a hands-on manufacturing experience.

Recognizing how much students enjoy learning about robots, the Student Summit has plenty on exhibit for everyone, Jones says. In the mechatronics area, most of the robot manufacturers that are exhibitors at IMTS 2022 also have a display in the Student Summit. For example, Festo Didactic features a smart factory automation and Industry 4.0 education system that will include four robots in its display. And Boston Dynamics enables educators and students to engage and control three of its “Spot the Robot” dogs.

To educate students and teachers about industry happenings, job opportunities and career paths, the event is hosting the TechEd Podcast on-site this year. Matt Kirchner, host of the podcast, is interviewing subject matter experts from a range of companies as well as some of the school staff in attendance to create the live podcast during the week.

Career Connections is another new feature that enables the older students in attendance to apply for manufacturing jobs in real time. “Because about a third of our audience consists of college and engineering school students, we want to provide them with an easy way to connect to jobs and apply for them right away,” Jones explains. A QR code, available on signage at exhibit partner booths within the Student Summit and at some exhibitor booths in the show halls, makes it simple for students to scan and apply for jobs immediately.

While the Smartforce Student Summit appears to focus on students’ interests, educators are not left behind. Educator professional development sessions are available during the event. Several OEMs and some of the ManufacturingUSA Institutes are collaborating to offer these educational sessions for teachers who hope to expand their manufacturing knowledge and share it with their students.

Related Content

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreUnattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)