Sustainable Metalworking with Minimum Quantity Lubrication

Companies involved in metalworking operations have an obligation to develop sustainable manufacturing solutions.

Companies involved in metalworking operations have an obligation to develop sustainable manufacturing solutions. Some might think this is a bold statement. While the idea of sustainability is becoming better defined and understood, many manufacturers are still not taking the necessary steps to implement newer, proven technologies that foster sustainability. But these capabilities are within closer reach than many of these manufacturers may realize.

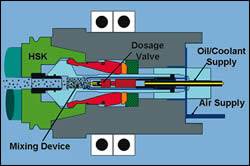

One such technology is minimum quantity lubrication (MQL), which eliminates large quantities of water and oil-based coolants and replaces them with a small quantity of lubricant mixed with air. This air-oil stream is precisely metered and delivered to the cutting tool’s edge. The philosophy behind MQL (also known as near dry machining) is based on a simple principle—more is not always better. Use only what is needed for the application, because enough is as good as a feast.

Manufacturers applying MQL are reaping many sustainable advantages. Their workers are safer, with both short and long-term benefits. Operators, skilled tradesmen and engineers are no longer exposed to the toxicity, bacteria and fungi risks that come with traditional “wet” machining. The small amount of oil used for MQL is generally based on vegetables or esters, which are less harmful to humans. Our environment is cleaner because no used cutting fluids are left behind that require stringent disposal (this benefits everyone and helps change the “dirty” perception of manufacturing).

Oil and other wastes present significant disposal concerns and implications to our environment. While legislation and regulations specify mitigation to the environment, enforcement of this legislation is challenging, expensive and difficult. Metal chips produced during MQL machining are almost dry and are much cleaner than conventional approaches. Near-dry chips are easier to recycle and more valuable as a recycled material.

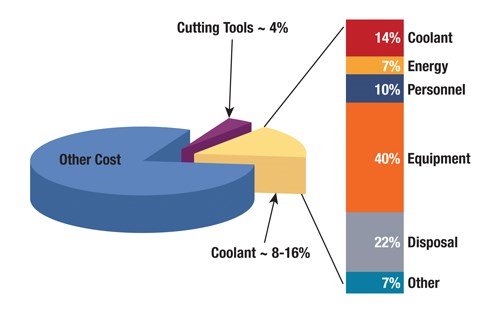

Most manufacturers still associate sustainability with higher costs. However, when the investment and operating expenses of “wet” manufacturing systems are broken down, the actual cost of these conventional systems becomes more apparent. Transferring, recycling and pressurizing coolant results in significant costs for coolant supply, filtration and mist collection equipment. Operating “wet” equipment produces increased and ongoing lifecycle costs in the form of energy consumption, chemical maintenance, water make-up, disposal of used cutting fluids, and then starting the cycle of waste/recovery all over again by replenishing consumed fluids.

Considering all of these benefits, why aren’t more manufacturers implementing MQL technology?

As an industry, we should behave more responsibly to implement sustainable manufacturing processes and systems in our factories. But often we hide behind the myth that sustainability adds cost. In the case of MQL, sustainability has proven to pay for itself, yet far too few manufacturers are insisting on MQL solutions. And the same can be said for other sustaining technologies. Perhaps the hesitation stems from fear of new technology or the cultural change associated with it.

These hurdles pose a real challenge for our industry. Until we answer them and have the courage to change our behavior, we cannot embrace a new idea like sustainability. So, what is the worst thing that can happen? The answer is that we may miss the next real technology opportunity to restore American manufacturing leadership—and no one can afford that.

— FFG MAG

Related Content

The Case for Higher-Performing Metalworking Fluids

Machine shops have the opportunity to enhance their profitability by choosing the proper metalworking fluids for each machining application.

Read MorePrecision Machining Technology Review September 2023

Production Machining’s September 2023 technology showcase includes some of the latest technology from Lyndex-Nikken Inc., Kurt Workholding, Master Fluid Solutions, Rego-Fix Tool Corporation and Jorgensen Conveyor & Filtration Solutions.

Read MoreVomat Coolant Filters Provide Precise Temperature Control

The company’s filters ensure a continuous supply of clean oil for microtool grinding applications.

Read MoreHeavy-Duty Synthetic Coolant for Machining, Grinding

PMTS 2023: Fortech’s TechKool FT4000 synthetic coolant is formulated to reject tramp oil that can cause smoking or misting and premature spoilage of coolant.

Read MoreRead Next

Understanding MQL

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More