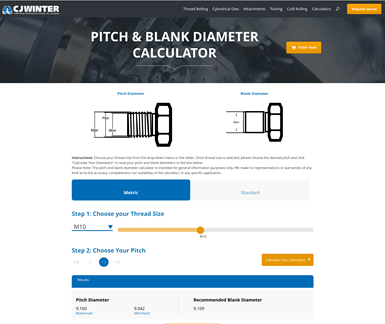

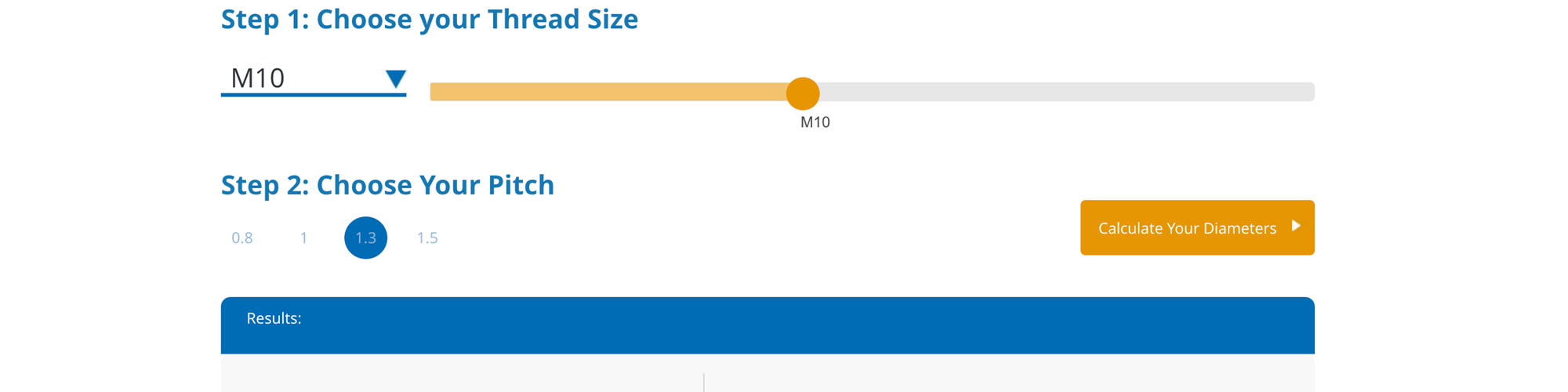

Users select the thread size and desired pitch to generate diameter and pitch values. (Photo credits: CJWinter)

When it comes to thread rolling, having the right tools can significantly streamline the process, ensuring accuracy and minimizing downtime.

Unlike subtractive processes, thread rolling does not remove material but instead moves and molds ductile metals quickly and precisely into the thread form using a cold-forming process. Thread rolling is completed using a thread rolling attachment on a multi-spindle, Swiss-type or CNC lathe. During the process, the tooth form of the thread rolls protrudes into the outside diameter of a cylindrical blank workpiece to reform the surface. The extreme pressure from the thread rolls causes the blank material to flow outward into the cavity between the thread rolls. This produces thread geometry that mirrors that of the rolls.

CJWinter, a provider of thread rolling solutions, simplifies complex calculations for engineers and manufacturers with an array of thread rolling calculators. These calculators, which are available on the company’s website, are designed to optimize thread rolling operations. Here are four:

Pitch and Blank Diameter Calculator. Determining the pitch and blank diameter is crucial for achieving precise thread dimensions. By selecting the thread size and desired pitch, CJWinter’s Pitch and Blank Diameter Calculator instantly generates the required blank diameter, along with the minimum and maximum pitch diameter values. This saves users valuable time and ensures accuracy in setup specifications, enabling smoother attachment installation and operation.

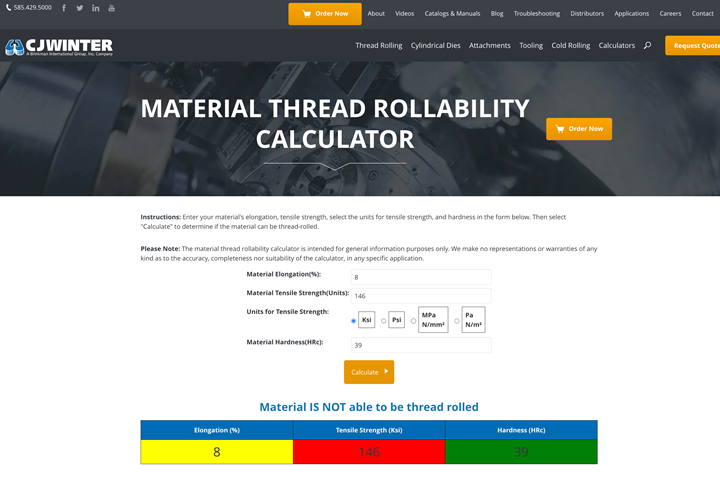

This calculator indicates whether the material is suitable for thread rolling.

Material Thread Rollability Calculator. Choosing the right material for thread rolling can be challenging. The company’s Material Thread Rollability Calculator simplifies this decision-making process by evaluating material properties such as elongation, tensile strength and hardness. With a simple input of these parameters, the calculator indicates whether the material is suitable for thread rolling. The color-coded results provide a quick visual assessment, enabling manufacturers to make informed material selections for optimal thread rolling performance.

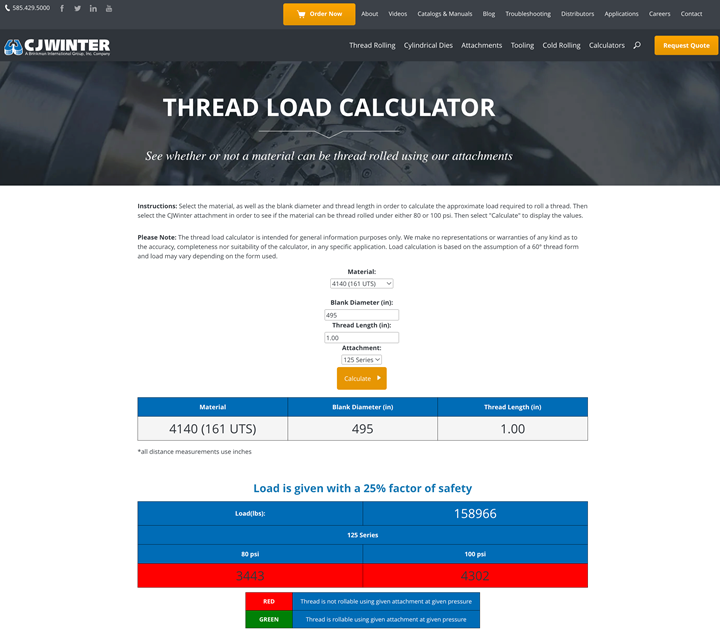

By providing load values at different rolling pressures, manufacturers can adjust parameters accordingly to achieve desired thread characteristics.

Thread Load Calculator. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. CJWinter’s Thread Load Calculator facilitates this by calculating the approximate load required based on material, blank diameter, thread length and the company’s attachment specifications. By providing load values at different rolling pressures, manufacturers can adjust parameters accordingly to achieve desired thread characteristics. The calculator’s interface and visual indicators are designed to simplify the process and enhance user experience.

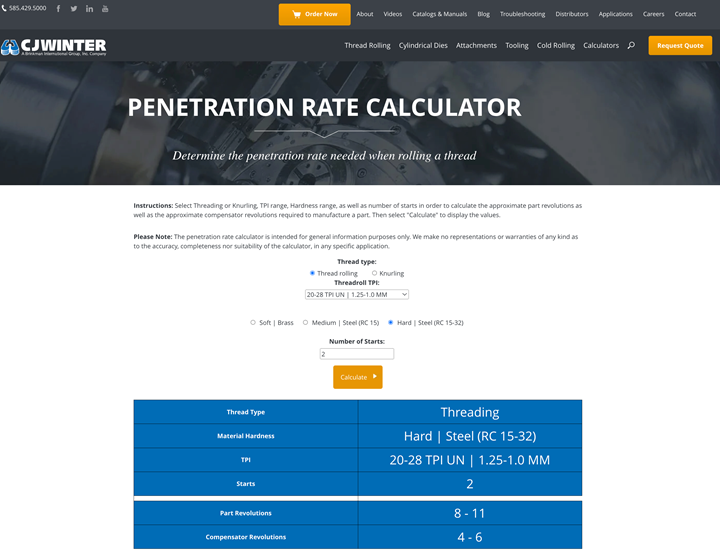

This calculator considers factors such as thread per inch (TPI), material hardness and number of starts.

Penetration Rate Calculator. Achieving the right penetration rate is vital for thread forming and knurling operations. The company’s Penetration Rate Calculator streamlines this calculation by considering factors such as thread per inch (TPI), material hardness and number of starts. By inputting these parameters, the calculator computes recommended part revolutions and corresponding compensator revolutions, optimizing production efficiency while maintaining quality standards. This tool enables manufacturers to fine-tune their processes for optimal performance and productivity.

By providing accurate calculations and intuitive interfaces, these calculators simplify complex tasks, reduce errors and enhance overall efficiency. As CJWinter continues to expand its knowledge database, users can expect ongoing advancements and improvements with the manufacturing processes.

Related Content

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreMicromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MoreBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.png;maxWidth=300;quality=90)