Shrink-fit collets can speed setups for CNC lathes that have live tooling stations while enabling those machines to perform more aggressive milling operations.

Haimer’s Power Clamp Preset i4.0 offers shrink-fit technology for ER collets for live-tool lathes. Photo Credit: Haimer USA

Shrink-fit toolholders have traditionally been used only on milling machines or turn-mills with a B-axis main spindle, offering advantages such as high tool clamping forces to enable more aggressive cuts. Now, the technology can be applied to live-tool lathes, realizing the same benefits in the form of shrink-fit ER collets from Haimer USA that work with the company’s shrink-fit machines.

Haimer USA has started to focus on the turning market recently and, as a result, has developed a shrink-fit toolholding process for collets that was designed with the added benefit of a built-in tool length presetter. The two processes are combined to save the operator time at the lathe during setups, and provide high accuracy, gripping force and balance repeatability in the machine tool.

Heat Up, Cool Down, Preset

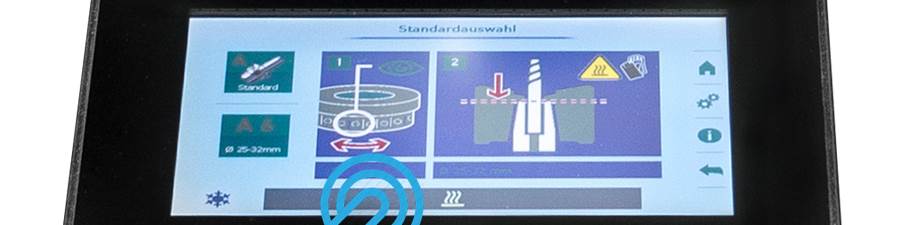

The shrink-fitting process for ER collets begins with a shrink-fit machine having an induction coil, such as Haimer’s Power Clamp Preset i4.0, and a specially designed, solid shrink-fit collet. With the tool presetting functionality on the shrink-fit machine, the operator sets the stick-out length of the cutting tool from the collet to the end of the tool. Then, he/she scans a data matrix code that is printed on the collet. The code produces information on the machine’s display that tells the operator where to position the heat induction coil. Next, the operator moves the coil down onto the collet, which starts the heating cycle, reaching as high as 350°C.

Within three to four seconds, the collet bore opens enough to be able to insert the cutting tool. When the operator inserts the cutting tool into the collet, he/she also lifts the cutting tool to the height gage stop disc that was set prior to beginning the shrink-fit process.

Then, the operator moves the collet configuration to the air cooling system, which evenly distributes cool air and a small amount of mist that cools down the metal in about 30 seconds. The system’s sensor measures the temperature, and a light turns green when the toolholder assembly has cooled. The tool is always clamped the same way with a runout accuracy of less than 0.003 mm.

Fast and Easy Tool Changes

Time savings is one of the major advantages of integrating shrink-fit technology because the process of presetting the tool is done on a shrink-fit machine — not at the lathe. Therefore, offline tool changes with solid shrink-fit collets take about 1 minute while the machine tool is still running, the company says. This is a much faster time compared with standard ER collets

The shrink-fit machine’s 7” touch display is water-, scratch- and impact-resistant, and offers a user-friendly interface with language selection. Photo Credit: Haimer USA

with slits that need to be cleaned by the operator once the old tool is taken out of the bore. Plus, once the new tool is put in the collet and the assembly is installed in the lathe, the operator must measure tool length. With these extra steps involved, the time can take up to 3 minutes with a standard ER collet.

Brendt Holden, president at Haimer USA, explains another disadvantage to using ER collets in a turning center. “In some cases, the door is left open on the machine during a tool change,” he says. “So the temperature is changing, which is a negative because by the time the new tool is installed the first parts might be scrapped because of the change in temperature.”

Expanding the List of Benefits

Besides reduced setup times and low contamination, shrink-fit technology offers high runout accuracy, high rigidity and high clamping force.

Time savings is one of the major advantages of integrating shrink-fit technology because the process of presetting the tool is done on a shrink-fit machine and, therefore, not at the lathe.

“Another disadvantage to ER collets is that there could be tool slippage,” Holden explains. “The tool can actually move because of aggressive cutting. With shrink-fit, you get high clamping force, so slippage is not going to happen.” This eliminates the need to reduce speeds and feeds as one might have to do with conventional ER collet toolholders, which increases cycle times.

Shrink-fit technology also provides consistently repeatable accuracy and balance repeatability because the holders have no collet nuts. Repeatable uniformity in the tooling setup and its results are another advantage because the technology does not leave room for errors or inconsistencies.

Designed for solid carbide tools with an h6 shank tolerance, shrink-fit collets are available in various lengths, and are suitable for driven units and spindles with an ER interface.

Haimer | haimer-usa.com

Related Content

Flexible, Quick-Change Tool Adapter System for Live Tools

The system significantly reduces inventory and changeover time for lathe users.

Read MorePSZ Turn Modular Quick-Change System for Swiss Lathes

Sumitomo’s PSZ Turn system provides good ergonomics and efficiency by offering a fast, reliable process and convenient cassette changes.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MorePiezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More

.png;maxWidth=300;quality=90)