Thread Grinding with ‘A’ Axis

With several factors propelling a surge in demand for parts with technically complex external and internal threads with large pitches, the need for better accuracy and efficiency has created challenges.

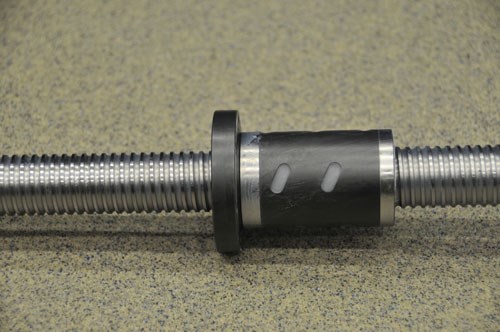

With several factors propelling a surge in demand for parts with technically complex external and internal threads with large pitches, the need for better accuracy and efficiency has created challenges. Investing in special grinding machines has typically been the first choice for such parts, but another option is now available. Studer (represented in the U.S. by United Grinding) has introduced the S41 and S22 cylindrical grinding machines with an A axis, allowing highly accurate grinding of recirculating ballscrews, thread gages, and thread rolls with large pitches. The A axis is a step toward complete machining in a single clamping when grinding such parts as recirculating ballscrews and worms. Other applications include multiple-start threads, internal and external thread gages, thread rolls, step drills, and general keyways with large pitch.

Previous Studer grinding machines used axis-parallel thread grinding processes, which, according to the company, covered about 75 percent of all desired thread types. The new process with the A axis is designed to address the remaining 25 percent by using a tilting grinding wheel adapted to the thread pitch angle.

Addressing a Need

Company specialists regularly received inquiries about methods for producing threads with a large pitch. Most of these customers did not have large enough batch sizes for these specific threads to justify the purchase of a special thread grinding machine, so Studer began planning the A-axis machine. Antonio Bottazzo, sales manager, says, “We had been planning the A axis for a long time, but then were able to develop it within a year due to the increasing market requirements.” Now, both the S41 and S22 grinding machines feature an additional A axis module for complex thread grinding.

Aware of some customer concerns, Erhard Kämpf, head of form and thread grinding at Studer, says, “The question arises regarding whether the cylindrical grinding machine with modular A axis can compete with a special machine.” He goes on to highlight the advantages. “The decisive advantage over special machines is that these are universal cylindrical grinding machines. Not only can they perform thread grinding perfectly, but they can also, depending on the grinding head variant (S41), perform complete machining operations. In other words, the workpieces are completely manufactured in a single clamping. This means that in most cases the process is both more precise and quicker.”

Increased Productivity

One of the first companies to use the A-axis machine is a manufacturer of cutting tools. The company previously manufactured its tools in a complex production process on four grinding machines. Today, the same processes are performed on an S41 machine with a swiveling wheel head and an integrated A axis. The machine performs a combination of cylindrical and thread grinding quickly within the specified tolerance limits. Not only does this grinding combination increase precision and productivity, but it also significantly reduces the processing time of the tools in production.

Productivity is the basis for cost effectiveness. An additional benefit of the S41 to increase productivity is the ability to be equipped with two A axes. Particularly advantageous in high production applications, one grinding wheel can be used for rough grinding (from solid) and the second can be used for fine grinding.

The A axis is also designed for internal thread grinding. Internal threads are particularly challenging if the bores are long. The StuderThread software is capable of compensating for angular pitches, which cannot be fully tilted because of the risk of collision between the wheel arbor and bore.

The new A-axis functionality may be especially appealing to customers who previously had to commission an external thread grinding specialist to produce components with complex thread geometries with large pitches. The A axis on the S22 and S41 now allows such components to be ground in-house in a single clamping. It is designed to provide a cost-effective solution by providing high productivity and flexibility.

Related Content

Carbon Fiber Spindles Aim to Eliminate Grinding Variance

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

Read MoreThe Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MoreShould You Bring Tool Regrinding In-House?

In some situations, the potentially high investment in an in-house tool grinding process can be justified with a relatively fast ROI. (Includes video.)

Read MoreGrinding Options for Dental Burrs and Rotary Instruments

Equipment to grind dental burrs continues to evolve. Here are five options for grinding these types of workpieces.

Read MoreRead Next

Beating the Competition by Not Making Products

An emphasis on process rather than creating products is the goal for some metalworking companies these days.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)