Using Grinding Instead of Turning in Series Production

By grinding the entire workpiece contour in a single operation, the Grindstar can produce large batch sizes economically, making it an alternative to turning for the automotive industry.

The Grindstar machine uses a method that enables the entire workpiece contour to be ground in a single processing operation. Junker’s experts adapt the system to meet the specific needs of each customer, from profiling through coating of the grinding wheels to the individual machine settings.

When manufacturing small components with diameters between 2 and 20 mm, the Grindstar grinding machine from Junker is designed to offer an economical alternative to turning. Its ability to produce batch sizes of 200,000, combined with its short cycle times and long workpiece service life, can drive down costs per workpiece by as much as 25%, according to the company. The Grindstar’s high productivity also makes it a particularly interesting alternative for large-scale series manufacturing in the automotive industry.

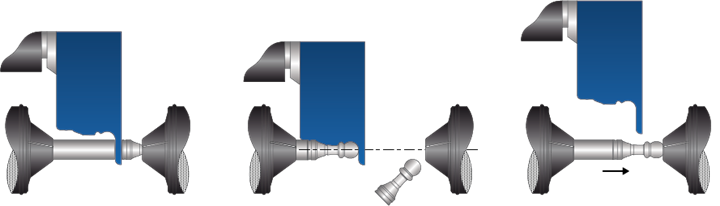

The machine uses a method that enables the entire workpiece contour to be ground in a single processing operation. In addition, because grinding involves lower cutting forces than turning, the Grindstar can quickly grind workpieces. The system also enables users to coordinate the workpiece, the abrasive and the machine for efficiency. These factors act together to increase the machine’s productivity so that it is as much as three times faster than a lathe, according to the company.

Revving Up Production

The high piece numbers and fast turnaround times demanded by the automotive and supply industry are a natural fit for the Grindstar’s strengths. Every work step, from material cutoff to profiling and ejection, takes place in a single machine, enhancing process reliability and minimizing machine downtime. As a result, the machine is said to be able to achieve an availability level of more than 96%, along with a long tool service life, according to the company. The Grindstar also has a special cooling system that helps ensure the grinding wheels work precisely and to a consistent standard of quality for as many as six months or a production volume of more than 300,000 pieces.

The use of grinding instead of turning can have a number of benefits. The Grindstar can improve dimensional accuracy and surface quality while eliminating the creation of burrs and chip impressions.

The Grindstar’s use of grinding instead of turning can have a positive impact on the quality of workpieces by improving dimensional accuracy and surface quality. It also eliminates the creation of burrs, and the company guarantees that workpieces that come off the Grindstar are burr-free. Additionally, unlike turning, grinding does not produce chip impressions.

The machine contains two profile grinding wheels that do not require dressing. The lubrication method’s flushing system prevents particles being deposited on the grinding wheels, eliminating the need for the reworking processes frequently required when turning. This reduces production time and can save companies the need to invest in additional machinery, such as surface grinders or polishing equipment.

The Grindstar has the flexibility to work with a range of materials. It can grind high-alloy tough steels, hardened materials and ceramics. It is also compatible with materials like curable plastics and glass fiber-reinforced plastics that meet the automotive industry’s increasing demand for lightweight technology. The grinding wheels are available with CBN and diamond abrasives, and Junker can help its customers choose the grinding wheel specifications that are best suited for which materials.

The Grindstar’s short cycle times and long workpiece service life can drive down costs per workpiece by as much as 25%, according to the company. Its high productivity makes it well-suited for large-scale series manufacturing in the automotive industry.

According to Junker, the Grindstar is more than just a grinding machine—it is a concept that can be adapted by the company’s experts so that it meets the specific needs of each customer. From profiling through coating of the grinding wheels to the individual machine settings, the company uses its in-depth expertise to plan the entire production process. This can eliminate the need for customers to perform laborious and costly test runs.

Related Content

3 Common Filtration Questions Answered

Learn about the variety of filters for removing particulates from a cleaning fluid, how to determine cleaning fluid life and more.

Read MoreApplying a Healthy Approach to Employee Investment

Service Center Metals’ on-site health center offers its employees and their families free same-day health care and, in return, the employer is gaining many benefits including a healthier workforce and attracting potential employees.

Read MoreImportant Machining Factors of Carbon Steels

Learn the factors that contribute to carbon steels and their machinability as well as the 1214 steels, 1215 steels and 1018 steels, other grades, and more.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)