Have you ever wondered: “Is there a search engine for 3D models?” It seems there is. And, it can be valuable to machine shops and manufacturers as well as product designers.

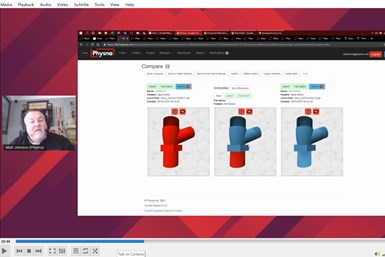

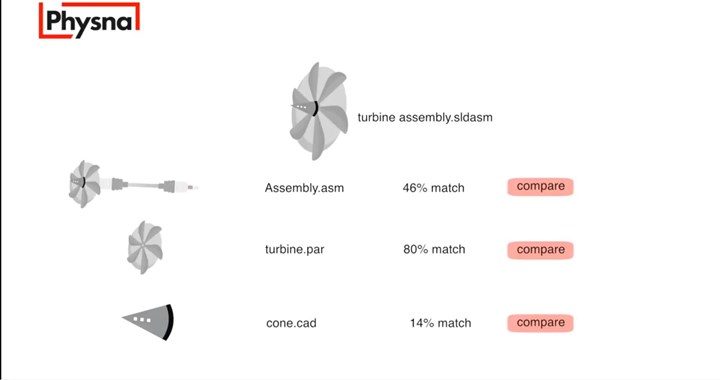

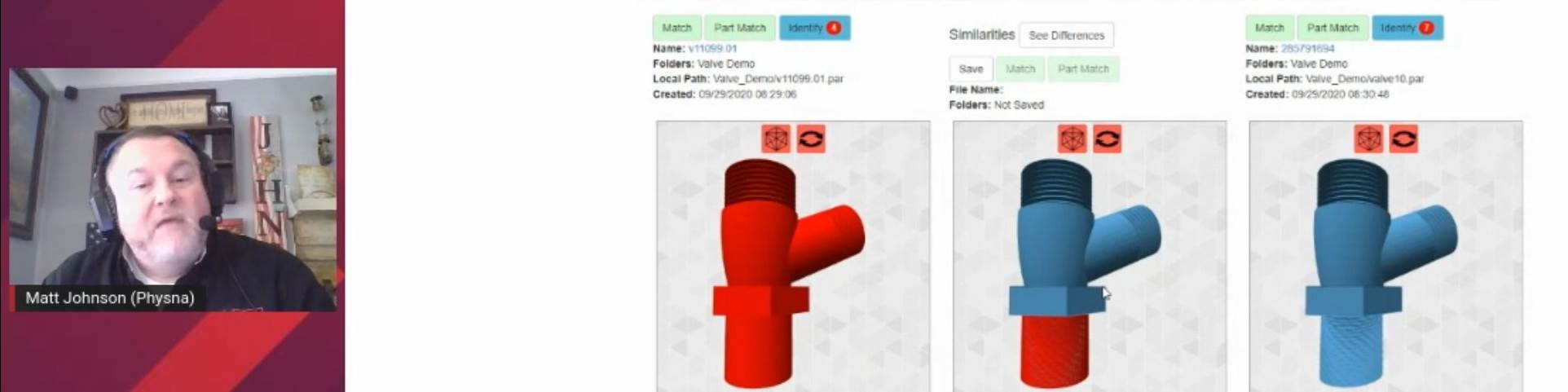

Cincinnati, Ohio’s Physna aims to bridge the gap between physical objects and digital code by analyzing CAD models and other 3D models to create a codified representation of a model — the “physical DNA” of that model. This digitized model enables Physna to show the detailed similarities and differences between models — even incomplete models or those with different file formats — as well as see all components in complex assemblies including parts contained in other parts.

In other words, it uses artificial intelligence to break down the structure of 3D models, analyzes them and determines how models are related to each other. The goal is to save engineering and product design teams many hours per person per year, reduce procurement costs, and enable anyone to immediately recognize parts and how they can be used.

But, machining operations can also benefit through faster quoting and tooling creation.

Physna uses artificial intelligence to break down the structure of 3D models, analyzes them and determines how models are related to each other.

Because it is challenging to capture and describe all the aspects of this technology in an article, I had the following discussion with Matt Johnson, Physna application engineer, who not only explained its value but also provided a demonstration showing ways designers and manufacturers might use it:

Related Content

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAD/CAM system. Here’s how the company succeeded despite the newness of it all.

-

Who Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

-

CAM Software’s Place Serving Emerging Trends

SolidCAM aims to align its product development and customer engagement strategies to address the evolving needs and challenges of the manufacturing industry.

.jpg;maxWidth=300;quality=90)