Video: How to Choose the Best Ultrasonic Cleaning Unit

Blackstone-Ney Ultrasonics covers ultrasonic cleaning beyond cavitation and implosion in this webinar.

If you already know the basics of ultrasonic cleaning and are ready for a deeper dive into its technical aspects, you will likely find this webinar titled “Ultrasonic Cleaning Beyond Cavitation and Implosion” to be helpful for gaining knowledge about how to choose the best ultrasonic cleaning unit for your application. The late John Fuchs, technology specialist, and Josh Kramlick, director of global sales, both from Blackstone-Ney Ultrasonics, a division of Cleaning Technologies Group, present on this topic and touch on:

- 19:05: Appropriate tank size and shape

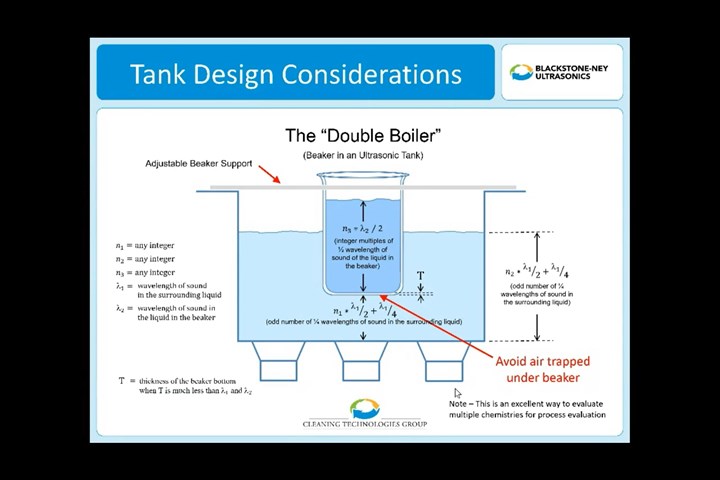

- 24:00: Advanced system configurations with a double boiler

- 27:28: Baskets and fixtures

- 35:11: Amplitude effect on cavitation

- 42:30: The effect of higher power and frequency

Thoughts about turbulation, verification of ultrasonic performance and degassing are also included in this video located on ’s YouTube channelProduction Machining.

When designing a double boiler tank, multiple wavelength separation between the inner boiler and the outer boiler tank must be considered to ensure good energy transmission for cleaning. Photo credit: Blackstone-Ney Ultrasonics.

Related Content

-

In-line Monitoring for Automated Immersion Cleaning Systems

Ecoclean’s Acoustic Performance Measurement (APM) system provides in-line measurement of ultrasonic frequency and power in fully automated immersion cleaning systems on a batch-by-batch basis or at defined time intervals, such as once a shift, day or week.

-

Parts Cleaning Sector Shifts Energy Toward Regulatory Changes

With changes in EPA regulations regarding the use of some popular cleaning fluids, cleaning suppliers and end users are readjusting business strategies and/or cleaning processes to meet new requirements.

-

3 Common Filtration Questions Answered

Learn about the variety of filters for removing particulates from a cleaning fluid, how to determine cleaning fluid life and more.