Watkins Manufacturing Inc.

Watkins Manufacturing has been doing business in the Cincinnati area since the late 1800s. The company manufactured a variety of products during its long history as a job shop. In the 1960s, Watkins developed a unique cutoff process for internal use.

Watkins Manufacturing has been doing business in the Cincinnati area since the late 1800s. The company manufactured a variety of products during its long history as a job shop.

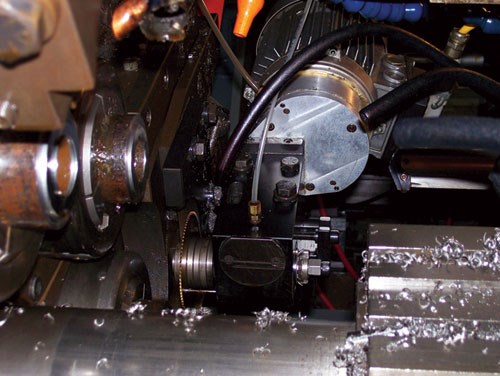

In the 1960s, Watkins developed a unique cutoff process for internal use. The process uses a rotating, circular saw blade to cut off, groove, mill and form barstock while the barstock is rotating. The self-contained, motorized attachment that drives the saw was originally known as the Kerf Cutter, a name that refers to the space that is left after a cut has been made.

The method was such a breakthrough that Watkins eventually ceased being a job shop and began manufacturing its rotary saw cutting system for sale to other job shops and OEMs. Today, the attachments are known as Watkins SAW-lution Systems, according to Natalie Greulich, the company’s marketing director.

In 1986, Ms. Greulich’s parents, Friedhelm ("Fritz") and Freia Greulich, purchased Watkins Manufacturing, including the SAW-lution System line of products. Ten years later, the company built its current plant, a 15,000-square-foot facility in Evendale, Ohio, a Cincinnati suburb. There, Watkins continues to conduct research and engineering to improve its systems and advance this cutting process.

"The process continues to gain in popularity as advances in technology and know-how allow it to be used in virtually all cutoff applications," says Ms. Greulich. "It can be used on steels, aluminum, brass, plastic and rubber. It will also cut thin-walled tubing, as well as irregular shapes such as hexes, squares and interrupted shapes.

"In turning applications, chip load is lower when using a rotating saw versus a single-point tool," Ms. Greulich continues. "Because only one tooth is cutting at a time, it removes a small amount of material. Advantages of the system include material savings, faster cutting times, closer tolerances and better finishes. The process is not just for cutting off. Most grooving and forming applications will benefit from the use of a saw rather than a single-point tool.

"The modular design of the SAW-lution System allows easy adaptation to many turning machines," Ms. Greulich states. "Standardized attachments and parts are available to fit most multi-spindle and single-spindle automatic screw machines. CNC turning machines with live tooling can also be outfitted with an arbor and a saw. Most of our customers are screw machine companies and many of them are PMPA members."

Watkins Manufacturing has been a PMPA technical member since 1996. "We have several people here that are very active in the PMPA on the local and national levels," says Ms. Greulich, who is the current chairperson for the local PMPA district serving southern Ohio and southern Indiana. Both she and her father have served on a number of PMPA committees over the years.

Watkins regularly sends its people to district meetings, the National Technical Conference, the PMPA Annual Meeting and PMPA Management Update. The company is actively involved in PMPA suppliers’ nights, with staff members visiting other districts to participate. "We were attending the suppliers’ nights before we became a PMPA member," Ms. Greulich says. "That led to our joining the association.

"At the PMPA suppliers’ nights, each supplier has a table-top display, so it levels the playing field," Ms. Greulich explains. "It allows us to compete with the bigger companies. Suppliers’ nights are also designed to be more educational than sales-oriented. So you end up having some good conversations with customers and other suppliers.

"I think one of the nicest things about the PMPA is that there are so many opportunities to get involved and to share know-how," Ms. Greulich continues. "The people here at Watkins are active in many different ways, through the Listserve and at the meetings. We also have given technical presentations on cutting with a saw. With PMPA, we have the opportunity to get to know our customers without that sales pressure. We’re not just walking into their locations once each quarter to sell.

"Because we are a small company, being a member of PMPA allows us to network with the people we specifically cater to," Ms. Greulich sums up. "It gives us credibility, especially on a national level, and allows us to have a voice alongside the bigger companies. Being a PMPA member really helps establish ourselves as the authority in our field."

Related Content

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)