New Cleaning Methods for Alternative Manufacturing Processes

Tyler Wheeler, product line manager at Ecoclean Group, covered the current manufacturing trends and how cleaning technologies are evolving to keep up with the cleaning demands of these trends.

Keeping abreast of manufacturing trends can be difficult and overwhelming. But when they are explained in detail in a 50-minute webinar that can be accessed any time and any place, it’s often a good idea to take advantage of the information in this easy format.

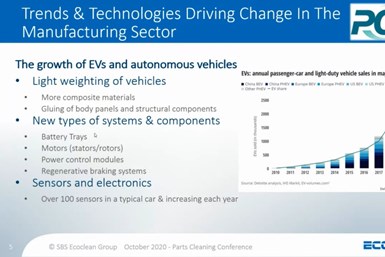

Ecoclean Group’s product line manager, Tyler Wheeler, presents, “New Cleaning Technologies Developed to Address New Manufacturing Processes.” In it, he covered the current manufacturing trends

and how cleaning technologies are evolving to keep up with the cleaning demands of these trends. He explained that with the development of additive manufacturing as well as the use of bonding and coatings the cleaning industry has had to adjust processes to fulfill cleaning requirements.

Here are some of the major points Wheeler makes during the presentation:

- The causes of these manufacturing trends

- Additive manufacturing cleanliness, including powder removal

- Surface cleaning with steam

- Wet and plasma cleaning for bonding and coatings

- Roughing, eroding and decoding

- Laser cleaning and surface preparation

- Cleaning electronics with carbon dioxide

- Cleaning with air

- Combination cleaning for different applications

To watch the video presentation in its entirety, click here.

Related Content

-

Overcoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

-

Environmentally Friendly Model 550 Versatile Parts Washer

PMTS 2023: This washer is useful in a variety of applications, including tool rooms, maintenance operations, low production and precision cleaning.

-

Kyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.