Video: The Advantages of CNC in a Cleaning/Deburring Process

This on-demand webinar from Sugino Corp. offers information on CNC waterjet for cleaning and deburring parts, pressure pumps and nozzle options for the system as well as how to add value to the process.

Combining waterjet cutting and CNC machining center technologies into a multi-purpose cleaning and deburring station brings consistency, repeatability and flexibility to a parts cleaning process. Don Reeder, general manager – sales, marketing and strategic development at Sugino Corp., presented on this topic in his on-demand webinar, “Benefits of CNC Waterjet for Cleaning and Deburring Parts.”

According to Reeder, with cleanliness standards increasing in difficulty each year, CNC-based cleaning machines will likely become the process of choice for OEMs and tier suppliers around the world.

The on-demand webinar covers the following points:

- The many benefits of using a CNC cleaning system

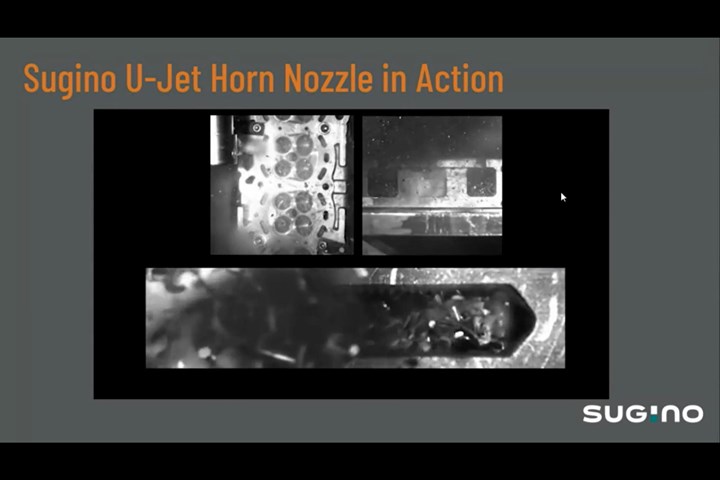

- Videos that illustrate how the CNC system cleans and deburrs

- High-pressure pumps and nozzle options

- Adding value to the process

- How Sugino Corp. can help build the right system for any application

Watch the webinar in its entirety here.

Related Content

-

Overcoming 3 Common Challenges With Automated Particle Counting

Facing difficulties while performing particle analysis is normal but should not be discouraging. Here are some ways to handle the most prevalent issues that can arise.

-

Cool Clean’s Omega 1500 Provides Powerful, Portable Cleaning

PMTS 2023: By selecting the appropriate nozzle and making the necessary propellant pressure and temperature adjustments, the Omega 1500 can clean to a variety of surface cleanliness levels.

-

Industrial Cleaning Shop Zeros In on Precision

This parts cleaning company is elevating its efforts to become a technical cleanliness expert, which presents an exciting, yet sometimes arduous, journey. The ongoing education of the team as well as significant investments in equipment and processes attribute to this shop’s success.