What's New and What's Next for Parts Cleaning

Three companies weigh in on what’s trending in parts cleaning right now. Keep up with the industry and find out more about the Parts Cleaning Conference at IMTS 2022.

Parts cleaning is a process most manufacturers are faced with at some point, whether it is done prior to a finishing process or before sending out a complete part to a customer. Regardless, it is a necessary operation that behooves most machine shop managers to stay abreast of the latest cleaning technologies and trends.

I spoke with three parts cleaning exhibitors at IMTS 2022 to get their input on what they are showcasing in their booths as well as the trends they are experiencing in the industrial cleaning segment.

Proceco Ltd. (Booth 121207) features its Typhoon-MB-S power spray-type belt parts washer designed for automatic processing and cleaning of workpieces in a continuous process. This conveyor part washer is especially useful for high-volume precision cleaning of parts and can be customized to a user’s needs. The Typhoon-SI spray immersion washer, also displayed at the show, is well suited for precision aqueous cleaning of machined components. Basket or fixture rotation during immersion and power-spraying is said to ensure precision cleaning and complete removal of contamination. The company’s multi-stage, customizable cleaning systems can meet virtually any cleaning process requirement in metal manufacturing, component maintenance and overhaul, the company says.

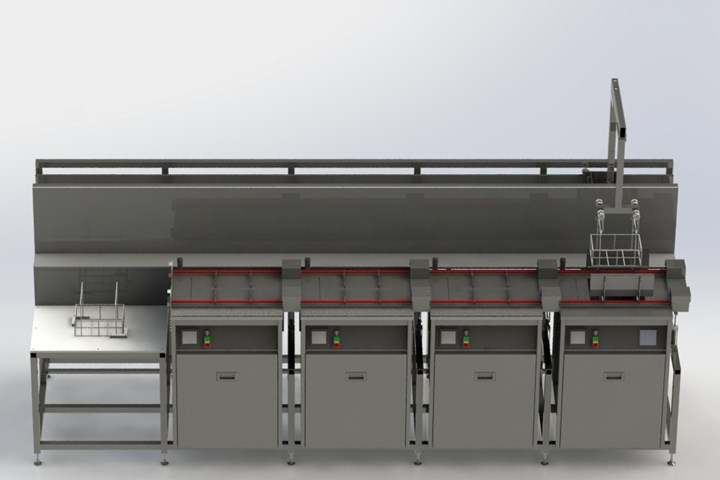

Offering flexibility and typically a shorter lead time, Miraclean Ultrasonics (Booth 121015) features its plug-and-play tanks. These individual, freestanding tanks can be customized for straightforward cleaning needs, including parts cleaning, rinsing and drying. Wet tanks can be ultrasonic or static and can include filtration and/or spray off. Multiple tanks can be modularized and linked together for water feed and draining. The system can be automated as well, which is the configuration shown in the company’s booth, with an attached PLC. As a division of Chautauqua Chemicals Co. Inc., Miraclean also supplies water-based cleaners, passivation chemistries and inhibitors.

Finding the appropriate detergent for a cleaning application is critical. Alconox (Booth 121340) can guide attendees in making this decision by helping them choose critical cleaning detergents based on efficacy, personal and environmental safety and meeting regulations.

Alconox provides offerings for any type of cleaning application and experience level. The company can educate customers and attendees on how to create the most efficient cleaning processes and help answer the question “How clean is clean?”

Also offered in the booth is its new citric acid-based passivation solution called Citrasteel that has cleaning capabilities as well. And its pH level meets national effluent standards.

“Many of our customers are leaning on us to ask about validation and to steer them in the right direction,” says Jeff Phillips, senior director, science and marketing at Alconox. “They ask about issues ranging from good passivation processes, how to remove difficult substances from parts, how to test for detergent residues and monitor the cleaning process. We strive to make sure your critical cleaning process is working within predetermined parameters.”

Cheryl Larkin, northeast regional sales manger for Miraclean, explains much of what the company builds are custom precision parts cleaning systems for complex applications. The systems tend to require longer lead times in terms of design, engineering and construction.

These plug-and-play tanks from Miraclean Ultrasonics provides flexibility and faster equipment lead time, plus a lower price point than the company’s more customized systems. Photo credit: Miraclean Ultrasonics

That’s why Miraclean is showcasing the plug-and-play system. It provides flexibility and faster equipment lead time, plus a lower price point than the company’s more customized systems, she says.

Automation is another trend she has seen over recent years. “Automation gives you greater process control, takes away concerns about operator error, and it’s trackable with data logging as well,” Larkin explains.

Electric vehicle (EV) component cleaning is another industry trend, according to Yoly Ramos, marketing manager at Proceco. “The whole industry is working toward this trend,” she explains. “Since 2020, we’ve had requests for cleaning systems with really stringent specifications for EV, and we’ve been developing systems that have surpassed our customers’ expectations.” She also says demand is increasing for ambient cleaning as well as for systems that meet tighter cleanliness specs in the remanufacturing industry. As a result, Proceco is constantly engaging in extensive research and development to meet these customer needs.

Parts Cleaning Conference at IMTS 2022

Cleaning processes and equipment are constantly evolving. While striving to stay abreast of the industrial cleaning industry trends and regulations, attending the 9th edition of the Parts Cleaning Conference (PCC) can be a boon to your cleaning knowledge. This year, the one-day conference on Tuesday, September 13, is co-located at IMTS and held in the East building. So, while visiting the cleaning exhibitors’ booths in the same building, attendees can take advantage of an education in parts cleaning efficiencies and technology. It is not too late to register onsite by scanning the QR code (and filling out the registration form at the link) on the event door at Room 353 in the East building.

The two-track event enables attendees to choose the topics that suit their interests, including “Solvents and Chemistry,” “Technology and Processes,” “Analysis and Special Applications” and “Challenging Substrates.”

The event begins at 8 a.m. with a “grab and go” breakfast and speaking engagements starting at 9 a.m. Lunch is included. The conference wraps up with question-and-answer sessions at 3:30 p.m. for each track, followed by a 4 p.m. reception for all PCC attendees and speakers.

Related Content

PMTS 2023 Product Preview: Parts Cleaning

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

Read MoreCool Clean’s Omega 1500 Provides Powerful, Portable Cleaning

PMTS 2023: By selecting the appropriate nozzle and making the necessary propellant pressure and temperature adjustments, the Omega 1500 can clean to a variety of surface cleanliness levels.

Read MoreSita’s CleanoSpector Measures Part Cleanliness

PMTS 2023: Handheld measuring device checks for cleanliness of parts to assure product quality as well as prior to follow-up processes.

Read MoreVersatile Sandblasting for Deburring Intricate Geometries

PMTS 2023: Comco’s MicroBlasting sandblasting systems can deburr, texture and clean small, intricate parts.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More